Feed-forward compensation control system and method for improving passive leveling system of hydraulic machine

A feed-forward compensation and control system technology, applied to presses, manufacturing tools, etc., can solve the problems of high energy consumption of the main cylinder, reduce the pressure of the lower chamber of the leveling cylinder, and affect the leveling effect, so as to meet the energy saving requirements and reduce the Lower cavity pressure, effect of ensuring tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

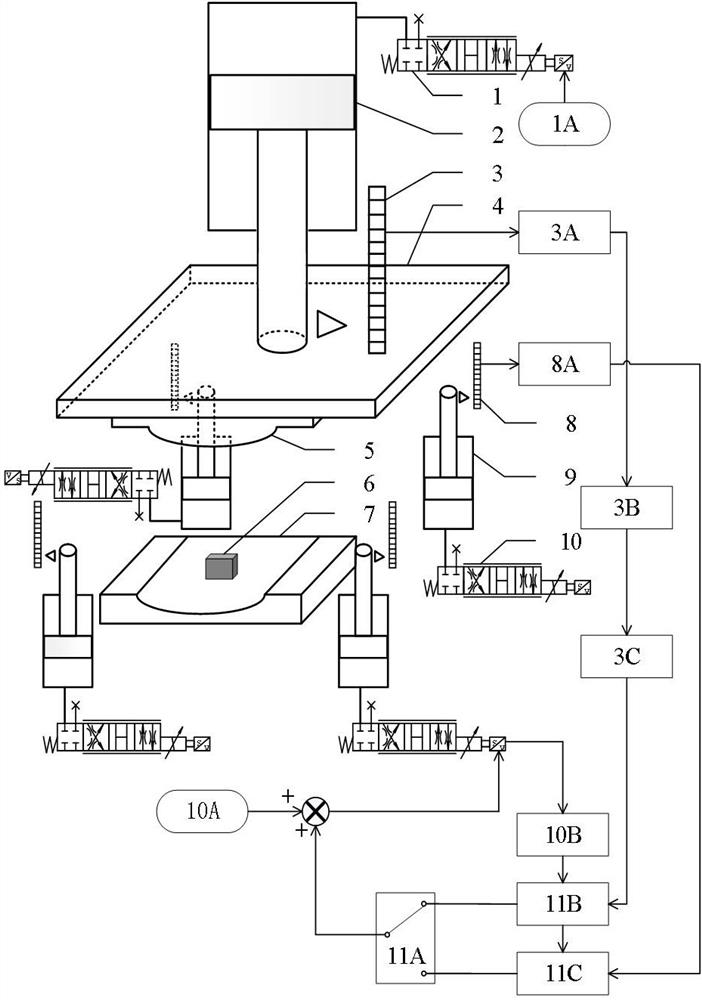

[0036] figure 1 Schematically represents the working principle of the present invention.

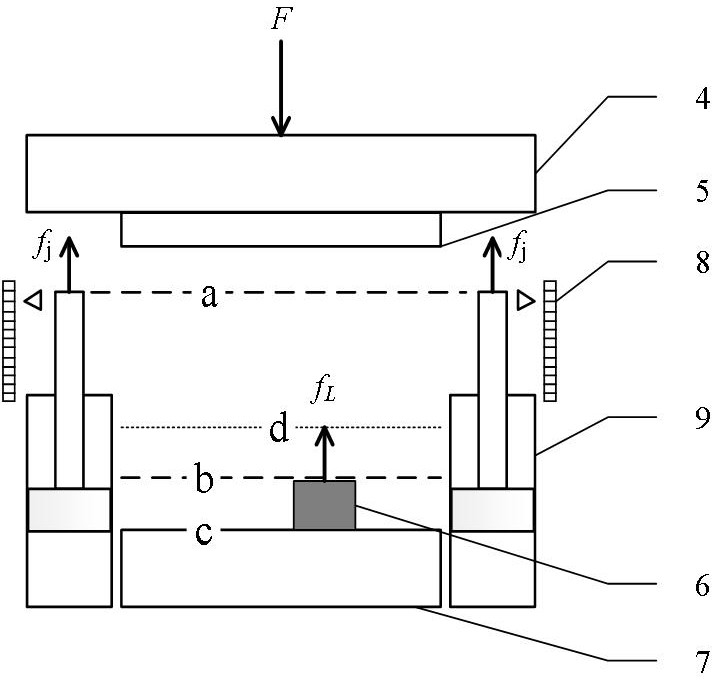

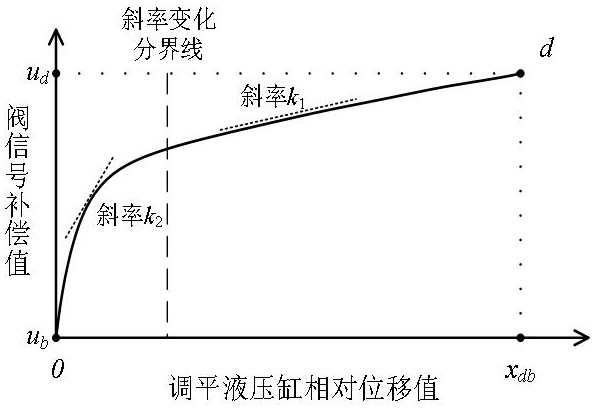

[0037] In this embodiment, the system composition of the hydraulic press includes a master cylinder drive system and a passive multi-hydraulic cylinder leveling system, wherein the direct drive objects of the master cylinder drive system are the movable beam 4 and the upper mold 5, the actuator is the master cylinder 2, The displacement variation of the master cylinder piston is the displacement variation of the movable beam and the upper mold. In the stage of multi-cylinder leveling, by giving the master cylinder control valve 1 a movable beam position control signal 1A, the feedback displacement 3A of the movable beam monitored by the displacement sensor is controlled according to the target displacement for closed-loop position control. The actuators of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com