Multi-head switchable stamper machine capable of supplementing printing ink

A stamping machine and stamping technology, applied in the field of stamping, can solve the problems of unclear stamping, time-consuming and laborious manual stamping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

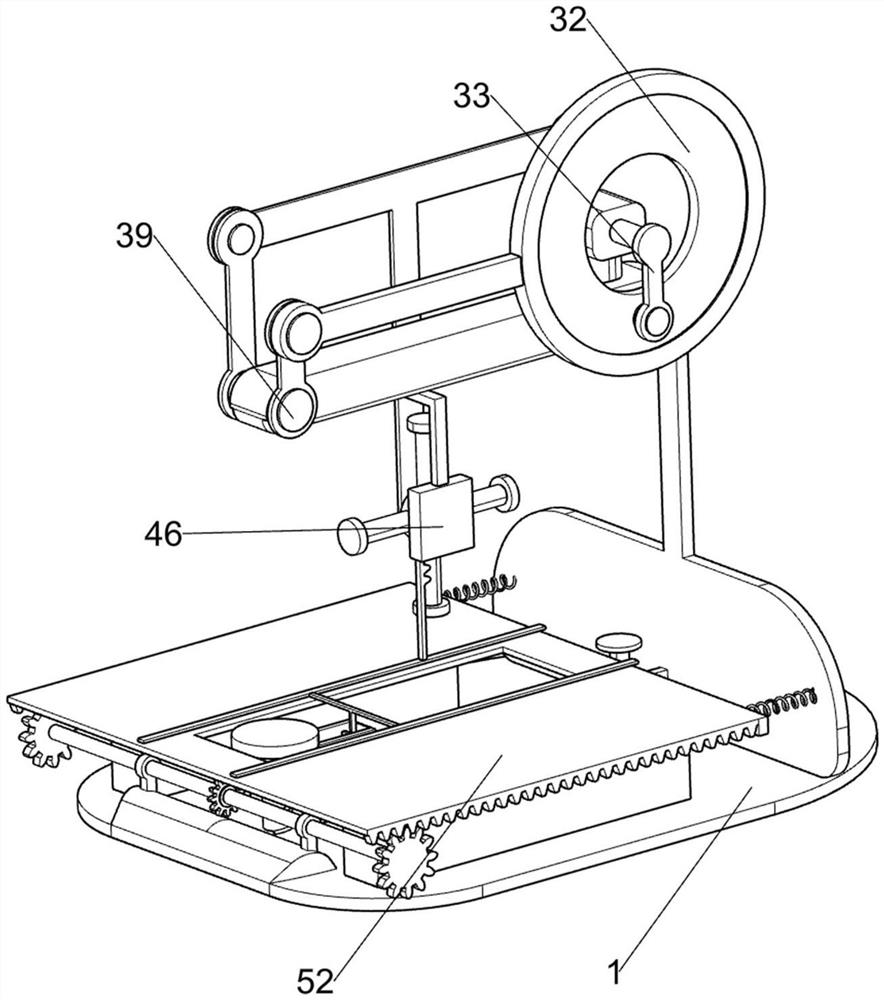

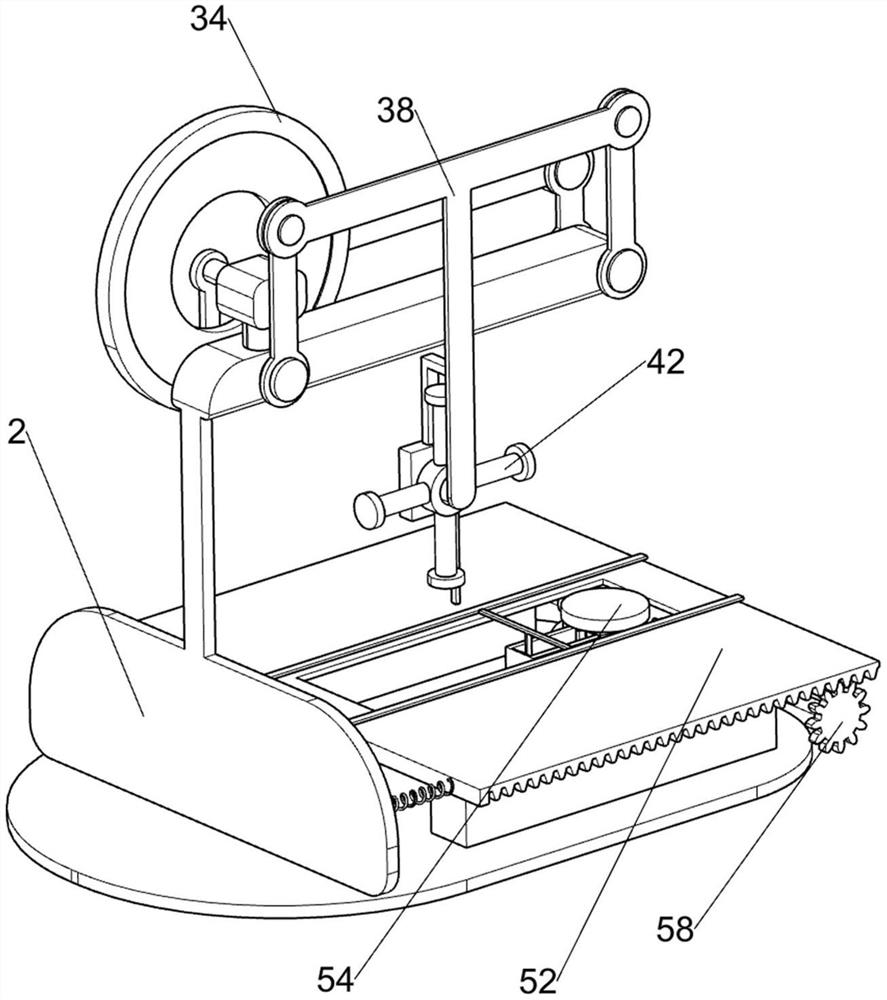

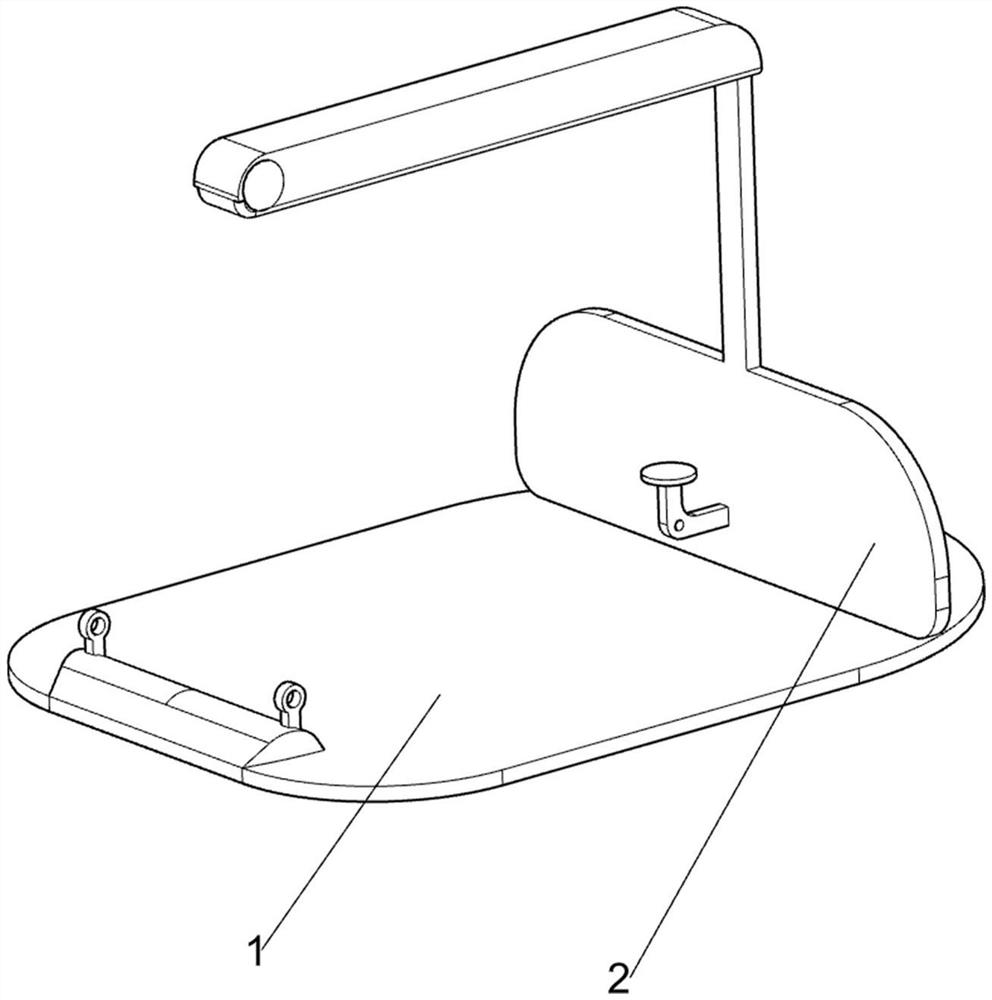

[0033] A multi-head switchable stamp machine that can replenish ink, such as Figure 1-11 As shown, it includes a base plate with bracket 1, a special-shaped support frame 2, an automatic seal ink replenishment mechanism 3, a seal rotation replacement mechanism 4, and a push mechanism 5. A seal automatic ink replenishment mechanism 3 for stamping and ink replenishment is installed. A seal rotation replacement mechanism 4 is installed at the lower end of the stamp automatic ink replenishment mechanism 3. The seal rotation replacement mechanism 4 is used to replace different seals. The push mechanism 5 is installed on the belt bracket. on base plate 1.

Embodiment 2

[0035] On the basis of Example 1, such as Figure 1-11 As shown, the stamp automatic ink replenishment mechanism 3 includes a motor 31, an eccentric wheel 32, a first short rod 33, a special-shaped rod 34, a second short rod 35, a first long rod 36, a second long rod 37, a T-shaped connecting rod 38 and connecting shaft 39, the motor 31 is fixedly connected on the special-shaped support frame 2, the first short rod 33 is fixedly connected to one end of the output shaft of the motor 31, and the first short rod 33 away from the motor 31 is connected to the eccentric wheel 32 in a rotational manner, and the special-shaped Rod 34 is fixedly connected on the eccentric wheel 32, and one end of the second short rod 35 away from the band bracket bottom plate 1 is fixedly connected on the special-shaped rod 34, and the special-shaped support frame 2 is connected with a connecting shaft 39 in a rotational manner, and one end of the connecting shaft 39 is connected to the second short rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com