Drilling-injection compound device and construction technology for grouting reinforcement of water-rich sand layer

A technology of grouting reinforcement and composite device, applied in soil protection, infrastructure engineering, construction, etc., can solve problems such as difficult sand layers, retention, and difficulty in forming holes, so as to improve permeability, achieve stability, and reduce infiltration sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

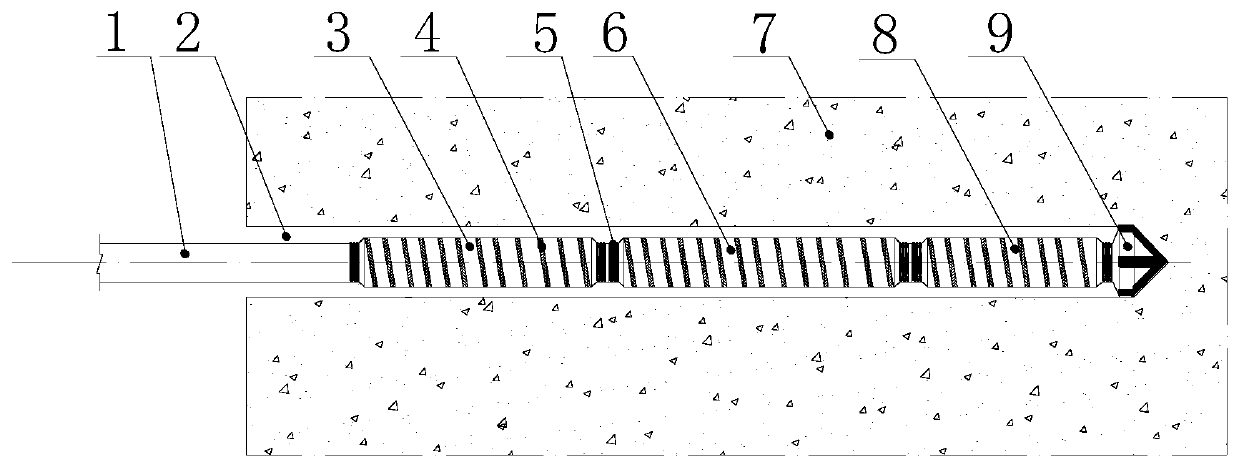

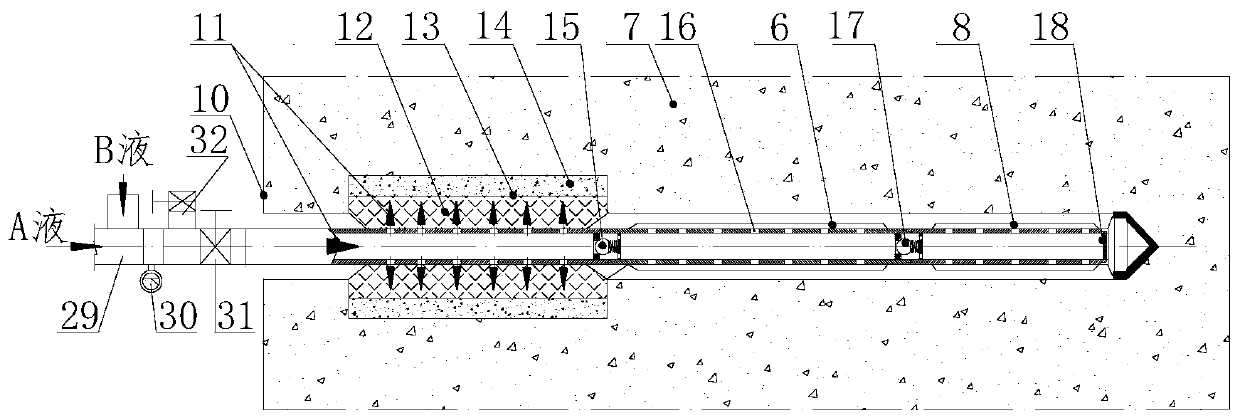

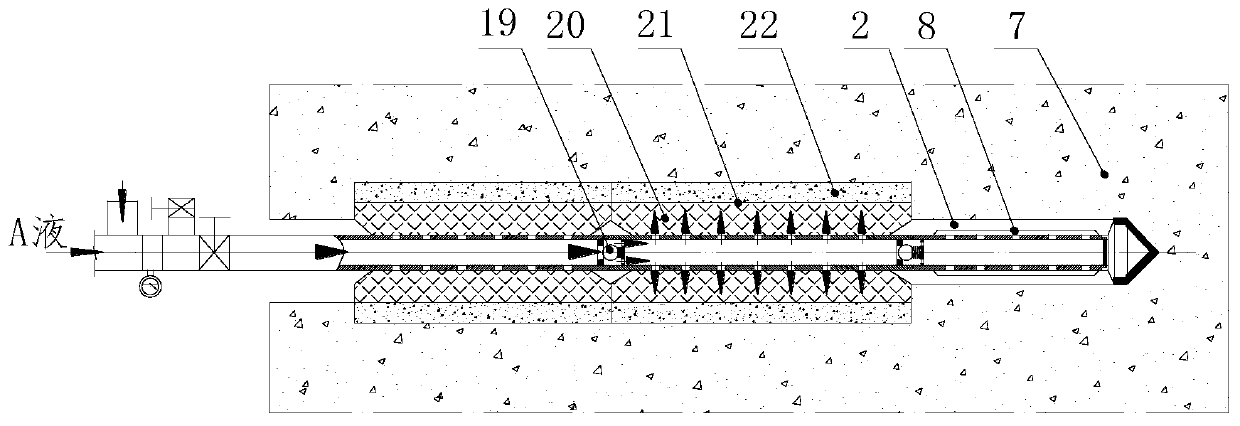

[0042]The structure of the drilling and injection compound device mainly includes: a multi-section grouting pipe 1; a grout containing body ( That is, slurry bag I3, slurry bag II6, slurry bag III8); the slurry bag is made into a barrel with cloth, and the two ends are bound on the grouting pipe, and when drilling, it is stacked and attached to the grouting pipe. After the grout is injected, it slowly opens and it expands during the grouting.

[0043] In order to meet the requirement of grouting into the grout containing body, the grout outlet hole 16 is cut on each section of the grouting pipe 1; in order to prevent the loss of the grout entering the grout containing body, the two ends of the grout containing body are bound to the grouting pipe 1 Iron binding belt 5 and sealant; located between adjacent grouting pipes 1 containing grouting bodies, che...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com