Ink storage device with interlocking type liquid level detection function and liquid level detection method

A technology for liquid level detection and ink storage, applied in printing and other directions, can solve the problem of not being able to send ink pumping instructions, and achieve the effect of preventing insufficient ink supply, abnormal printing work, and damage to the nozzle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

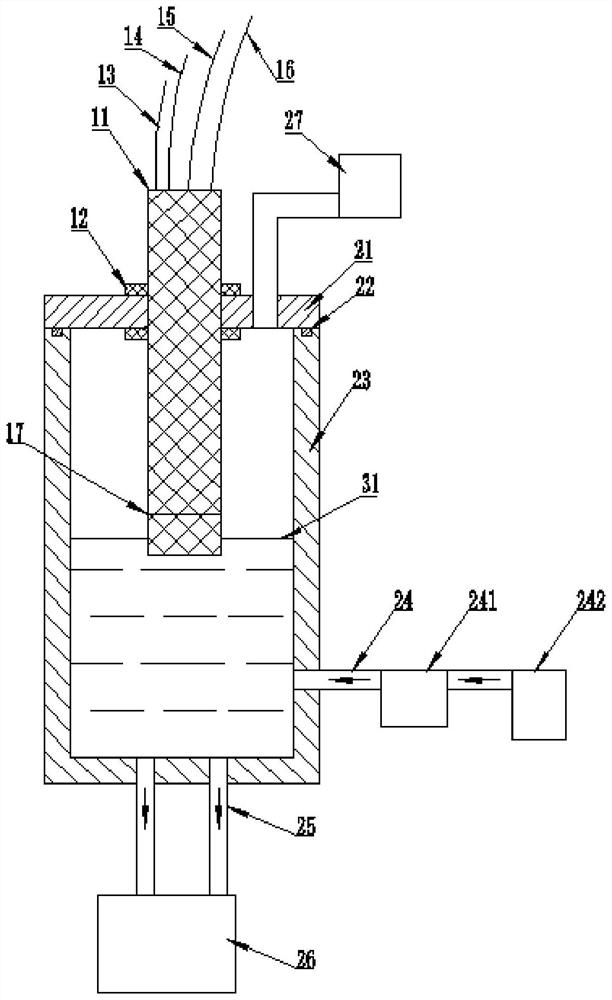

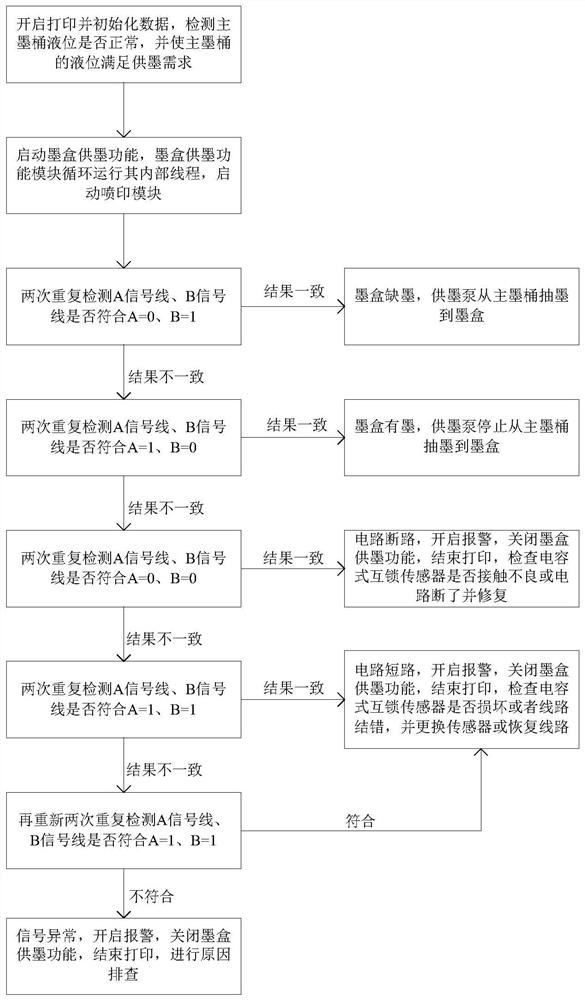

[0031] see figure 1 , The present invention provides an ink storage device with interlocking liquid level detection, including: a liquid level detection device, an ink cartridge assembly, a main ink tank, and a positive and negative pressure system 27 .

[0032] The ink cartridge assembly includes an ink cartridge 23 and an ink cartridge cover 21 , the ink cartridge cover 21 covers the top of the ink cartridge 23 , and a sealing ring 22 is provided between the ink cartridge 23 and the ink cartridge cover 21 to seal the inner cavity of the ink cartridge 23 . The ink cartridge 23 communicates with the main ink barrel 242 , and the main ink barrel 242 supplies ink for the ink cartridge 23 . The ink cartridge assembly is provided with a liquid level detection device to detect the liquid level 31 of the ink cartridge 23 .

[0033] The liquid lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com