Steel mould trolley with quick-release system and suitable for pipe gallery and construction method

The technology of a steel mold trolley and system is applied in the directions of earth-moving drilling, wellbore lining, tunnel lining, etc., which can solve problems such as low efficiency and achieve the effect of solving low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The various embodiments will now be described in detail, and one or more examples of these embodiments are shown in the drawings. Each instance is provided in the manner of explanation, rather than means limiting. For example, as a part of one embodiment, the features described or described can be used or combined with any other embodiment to produce a further embodiment. The present invention is intended to include such modifications and changes.

[0053] In the following description of the drawings, the same reference numerals indicate the same or similar components. In general, it will only be described for the different embodiments. Unless otherwise specified, the descriptions of the partial or aspects in one embodiment can also be applied to the corresponding portion or aspects of another embodiment.

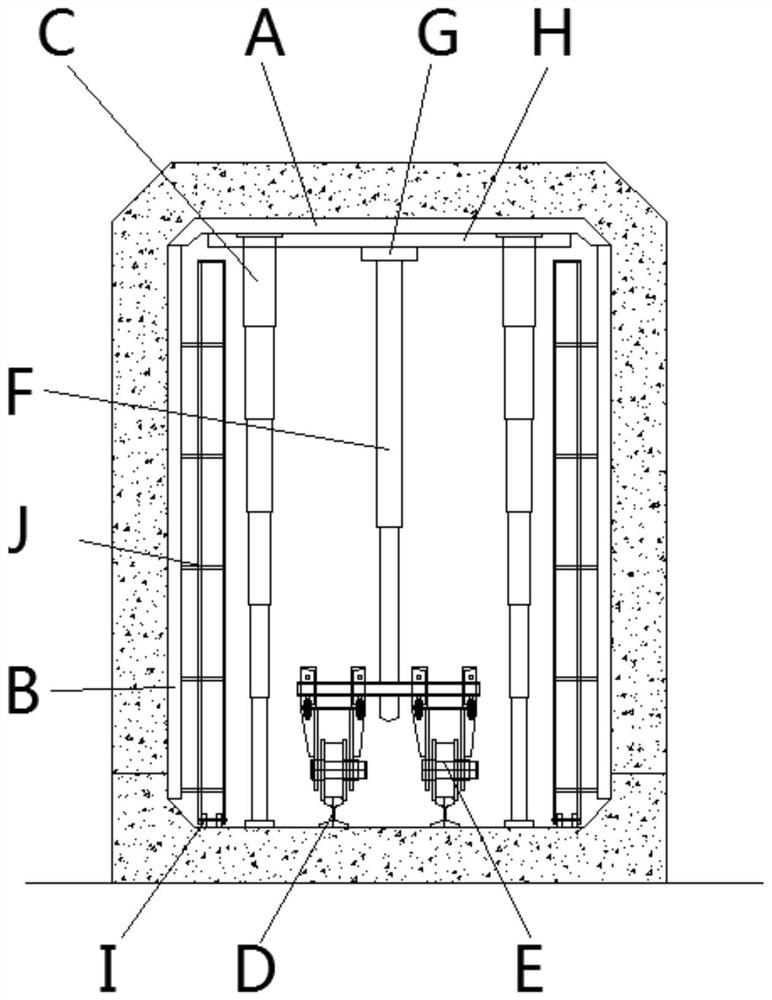

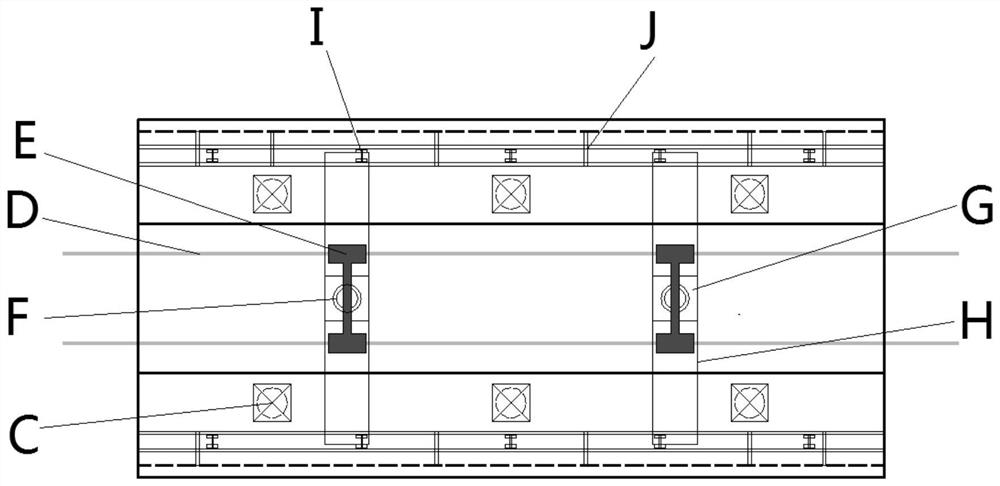

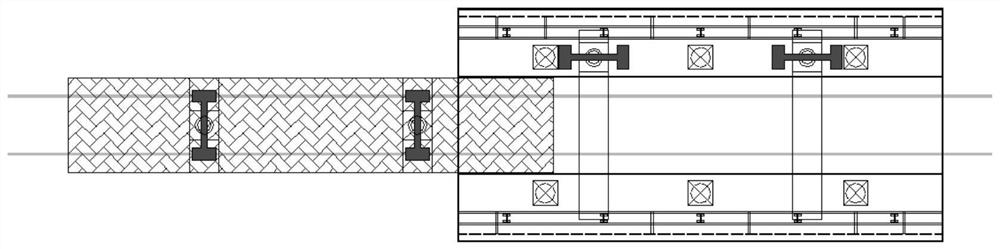

[0054] Such as Figure 1 to 4 As shown, steel mold cars suitable for the splitting system of the present embodiment, including: side wall template systems B, I, J and top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com