Pipeline air tightness detection device and method

A detection device, pipeline gas technology, applied in the direction of measurement device, fluid tightness test, pipeline system, etc., can solve problems such as ineffectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

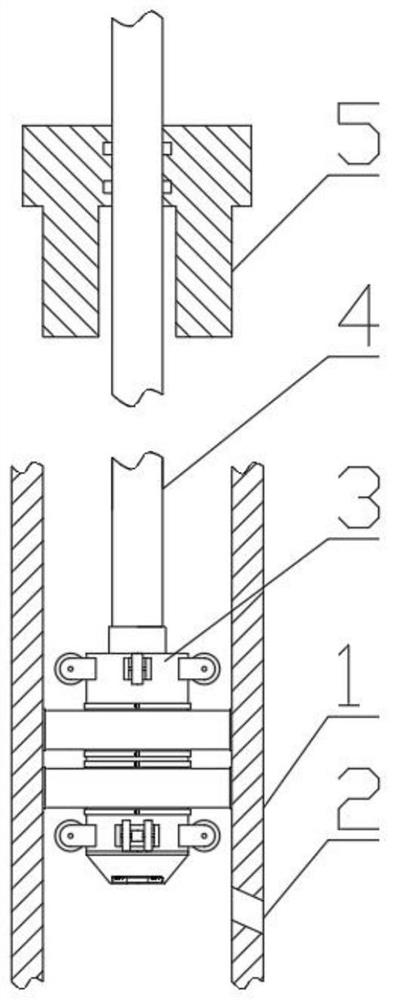

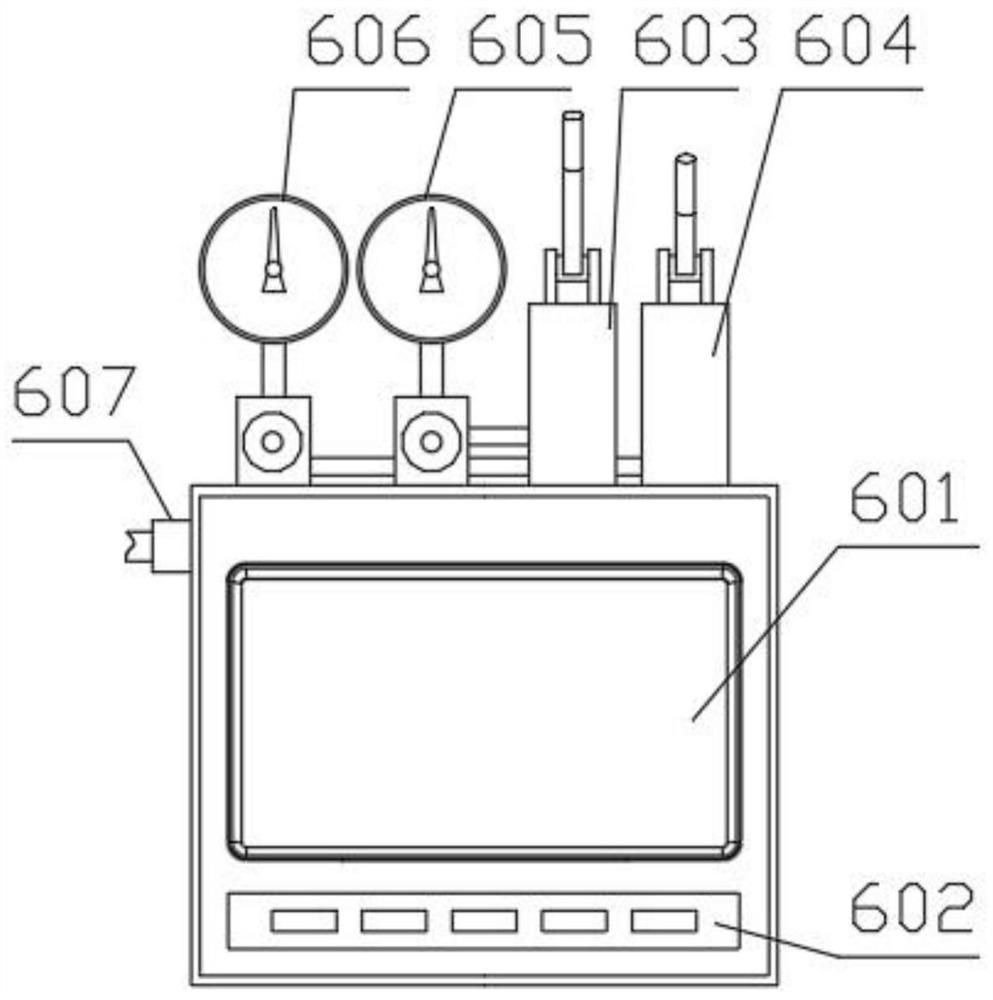

[0046] see Figure 1-Figure 17 , the embodiment of the present invention provides a pipeline airtightness detection device, including a detection head 3 that can extend into the pipeline 1 from the entrance of the pipeline 1 and block the pipeline 1, a hose 4 for supplying gas, and A detector 6 for detecting air pressure, the gas outlet of the detection head 3 located in the blocked pipeline 1 communicates with the gas outlet of the hose 4, and the air inlet of the hose 4 communicates with the detector 6 detection end docking. In this embodiment, the function of the detection head 3 is to find the location of the leakage point 2 in the pipeline 1, and the hose 4 has many functions, it can be used to provide gas, and can also be used as a passage for power lines and signal lines to pass through , can also play a role in cooperating with the movement of the detection head 3. These following embodiments will be described in detail. In this embodiment, one of its functions is to ...

specific Embodiment

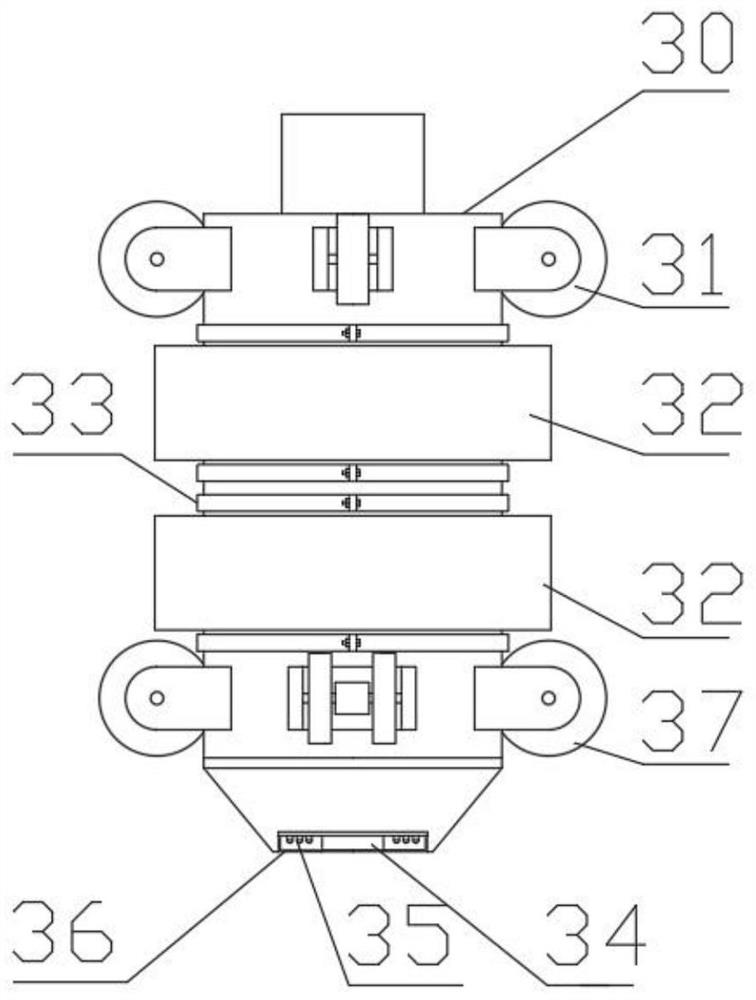

[0048] To refine the detection head 3 above, please refer to figure 1 , image 3 , Figure 4 and Figure 8 , the detection head 3 includes a main body 30 and an expansion ring 32 that can expand to block the pipeline 1 after inflating, the expansion ring 32 is sleeved on the main body 30, and the main body 30 has a first channel 304 and the third channel 306, the air inlets of the first channel 304 and the third channel 306 are connected with the air outlet of the hose 4, and the air outlet of the first channel 304 is located at the expansion On the circle 32, the gas outlet of the third channel 306 is the gas outlet located in the blocked pipeline 1 . In this embodiment, the hose 4 can not only fill the blocked pipeline 1 with gas, but also fill the expansion ring 32 with gas, and the expansion ring 32 will expand after being filled with gas, and its outer edge will become larger until it sticks to the wall. The inner wall of the pipeline 1 is connected to the inner wall ...

Embodiment 2

[0063] An embodiment of the present invention provides a pipeline airtightness detection method, comprising the following steps:

[0064] S1, extend the detection head 3 into the pipeline 1 from the entrance of the pipeline 1; S2, block the pipeline 1 to be detected in this section after the detection head 3 reaches the designated detection point; S3, block the section to the pipeline Fill the pipeline 1 with gas, and use the detector 6 to detect the air pressure change in the blocked pipeline 1; S4, observe the situation of the air pressure change reflected by the detector 6, if the section is blocked If the air pressure of the pipeline 1 continues to rise and does not fall back after rising, it is judged that the blocked pipeline 1 has no leak point 2, and then the blocked state is released, and the steps S2 and S3 are repeated; If the air pressure of pipeline 1 remains unchanged or rises slightly and then falls back, it can be judged that there is a leak point 2 in the bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com