Optical imaging system, image capturing module and electronic equipment

An optical imaging system and optical axis technology, applied in optics, optical components, sub-office equipment, etc., can solve problems such as poor photographing effect, poor imaging effect, and affecting user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

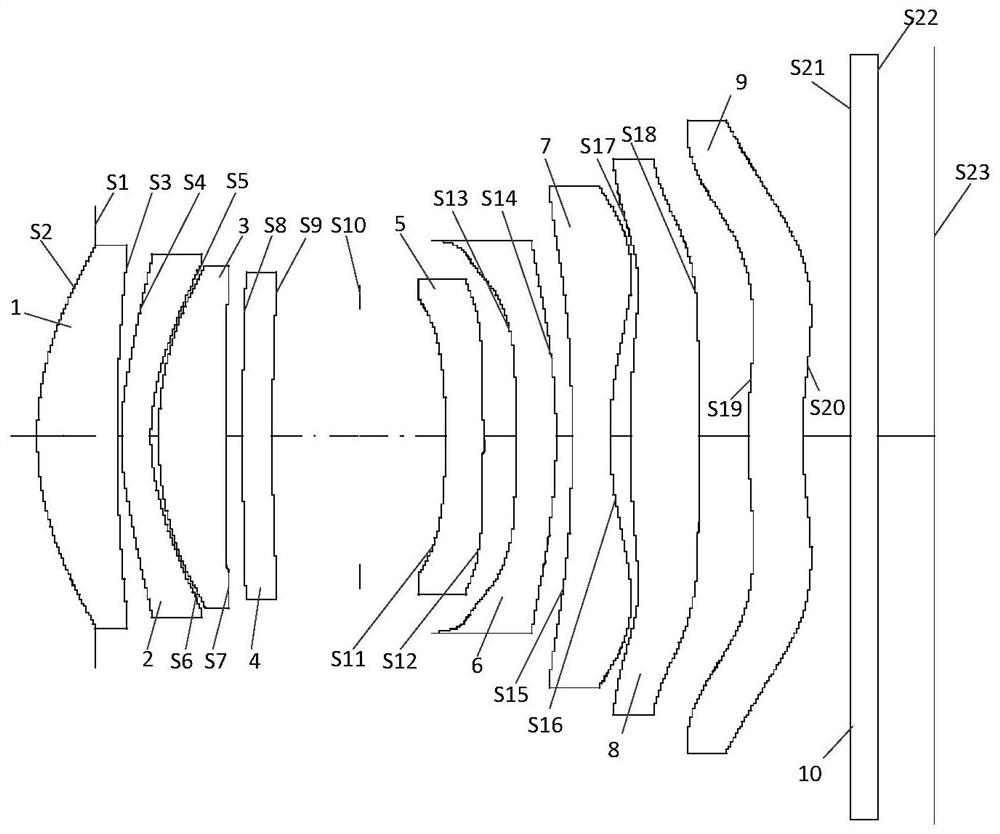

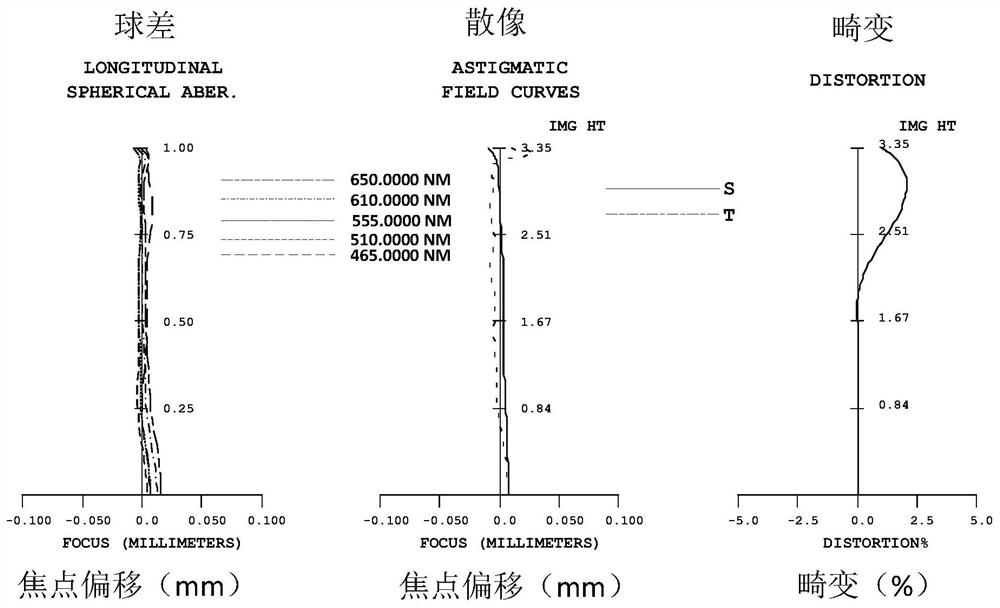

[0121] refer to figure 1 with figure 2 , the optical imaging system of the first embodiment includes sequentially from the object side to the image side: a first lens 1 with positive refractive power, the object side S2 of the first lens 1 is at the low beam The axis is convex, the image side S3 of the first lens 1 is concave at the near optical axis; the second lens 2 with negative refractive power, the object side S4 of the second lens 2 is at the near optical axis Convex, the image side S5 of the second lens 2 is concave at the near optical axis; the third lens 3 with positive refractive power, the object side S6 of the third lens 3 is convex at the near optical axis, the The image side S7 of the third lens 3 is concave at the near optical axis; the fourth lens 4 with negative refractive power, the image side S9 of the fourth lens 4 is concave at the near optical axis, and the fourth lens The object side S8 of 4 is a convex surface at the near optical axis; the fifth len...

no. 2 example

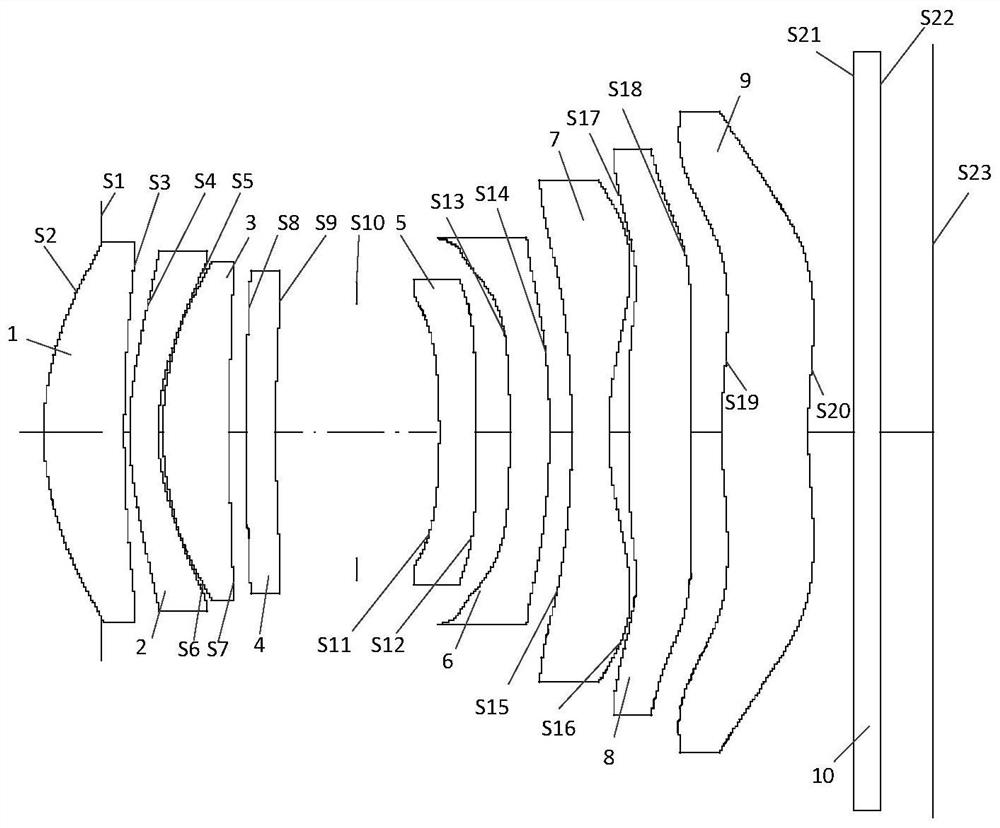

[0133] refer to image 3 with Figure 4 The optical imaging system of the second embodiment includes sequentially from the object side to the image side: a first lens 1 with positive refractive power, the object side S2 of the first lens 1 is at the low beam The axis is convex, the image side S3 of the first lens 1 is concave at the near optical axis; the second lens 2 with negative refractive power, the object side S4 of the second lens 2 is at the near optical axis Convex, the image side S5 of the second lens 2 is concave at the near optical axis; the third lens 3 with positive refractive power, the object side S6 of the third lens 3 is convex at the near optical axis, the The image side S7 of the third lens 3 is concave at the near optical axis; the fourth lens 4 with negative refractive power, the object side S8 of the fourth lens 4 is convex at the near optical axis, and the fourth lens The image side S9 of 4 is concave at the near optical axis; the fifth lens 5 with ne...

no. 3 example

[0144] refer to Figure 5 with Image 6 , the optical imaging system of the third embodiment includes in turn from the object side to the image side: a first lens 1 with positive refractive power, the object side S2 of the first lens 1 is at the low beam The axis is convex, the image side S3 of the first lens 1 is concave at the near optical axis; the second lens 2 with negative refractive power, the object side S4 of the second lens 2 is at the near optical axis Convex, the image side S5 of the second lens 2 is concave at the near optical axis; the third lens 3 with positive refractive power, the object side S6 of the third lens 3 is convex at the near optical axis, the The image side S7 of the third lens 3 is concave at the near optical axis; the fourth lens 4 with negative refractive power, the object side S8 of the fourth lens 4 is convex at the near optical axis, and the fourth lens The image side S9 of 4 is concave at the near optical axis; the fifth lens 5 with negati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com