A three-phase permanent magnet synchronous motor assembly method

A technology of permanent magnet synchronous motor and assembling method, which is applied to electromechanical devices, electric components, manufacturing electric generators, etc., can solve the problems of inconvenient assembly, difficult assembly of end caps, etc., and achieve the effects of easy handling, simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

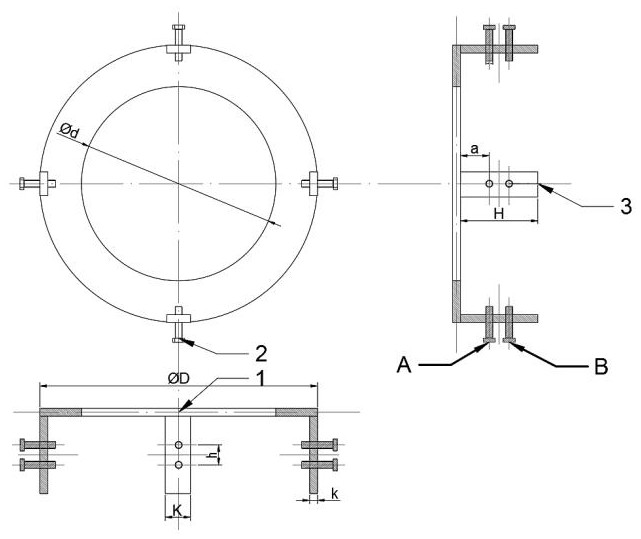

[0032] figure 1 The tool structure of the present invention is illustrated. As shown in the figure, a tool used in a permanent magnet synchronous motor assembly method includes: a main body steel plate 1 , a stainless steel bolt 2 , and a bolt positioning steel plate 3 .

[0033] A three-phase permanent magnet synchronous motor assembly method, the tool part used comprises: a main body steel plate 1, a stainless steel bolt 2, a bolt positioning steel plate 3; the main body steel plate is composed of a circular steel plate with a diameter of ФD and a circular steel plate with a diameter of Фd removed ; The stainless steel bolts are composed of M18*160 stainless steel bolts; the bolt positioning steel plate is welded by a steel plate with a length of 200mm and a width of 65mm.

[0034] (1) Main steel plate: used to fix the bolt to locate the steel plate. Because the permanent magnet synchronous motor shaft protrudes from the motor end caps at both ends for a certain distance, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com