An efficient cleaning device for dispensing workbench for intelligent manufacturing

A technology for intelligent manufacturing and cleaning devices, which is applied in the direction of cleaning methods using tools, cleaning methods using liquids, cleaning methods and utensils. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

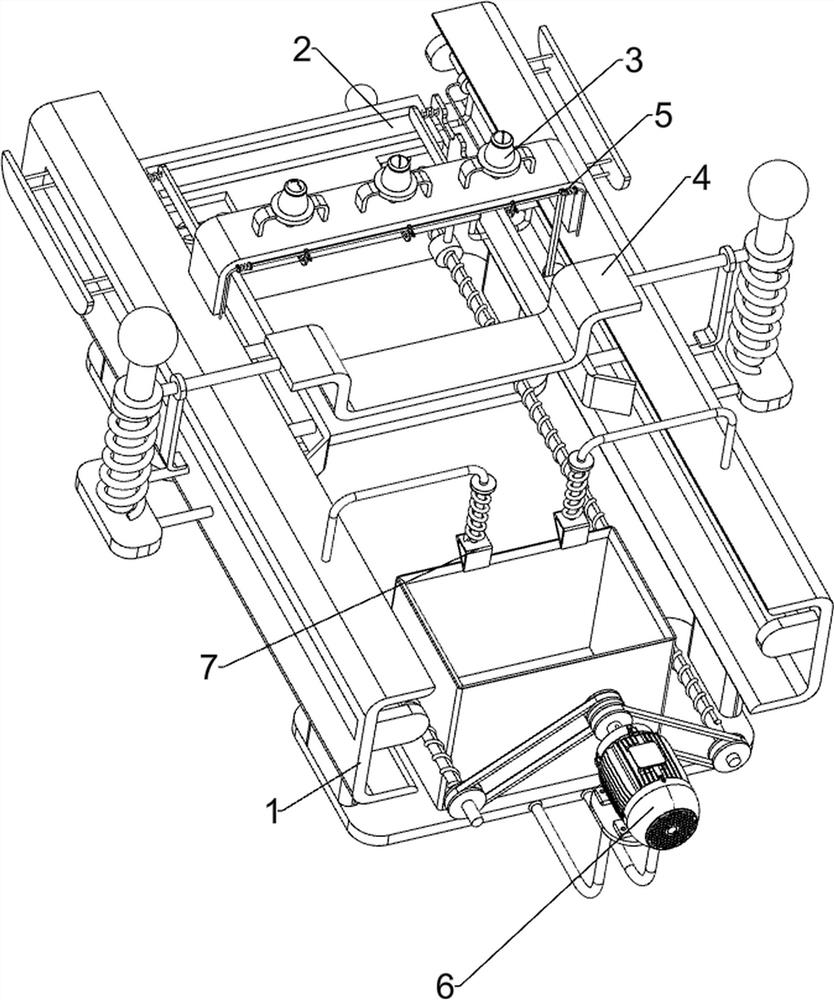

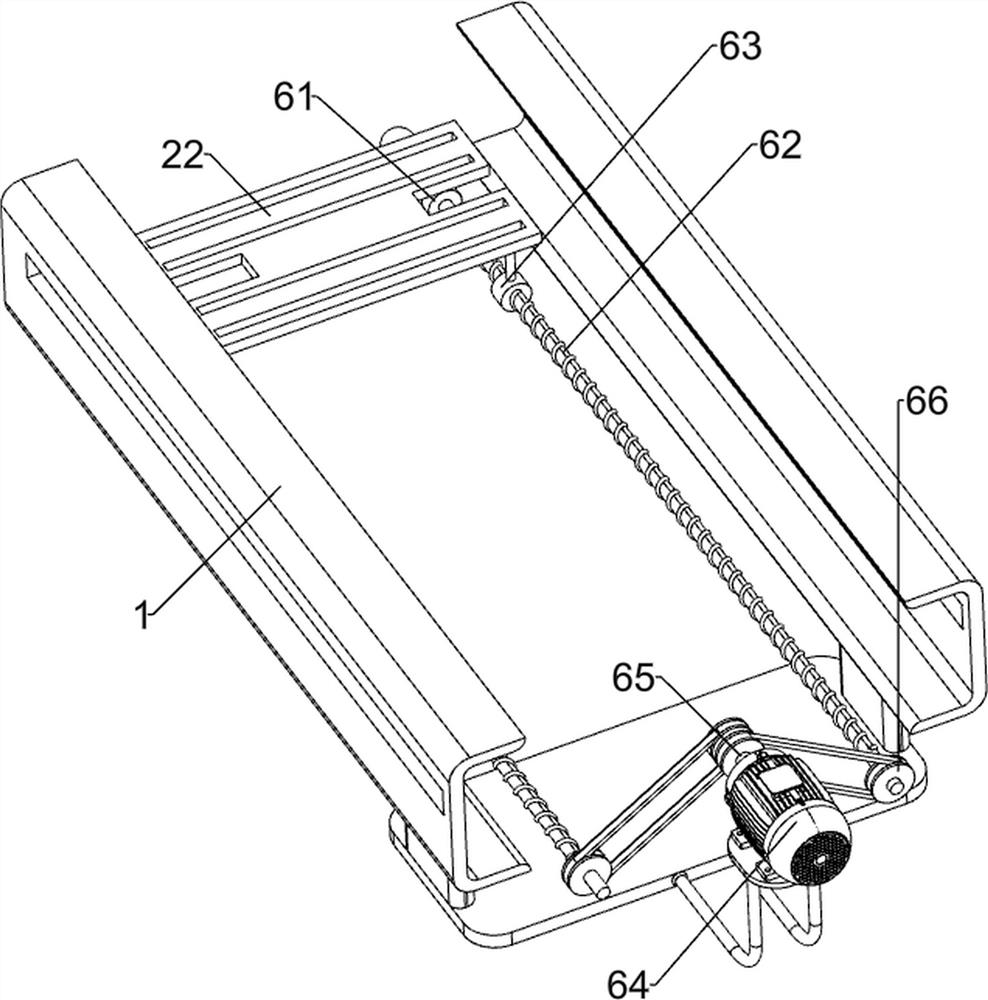

[0028] An efficient cleaning device for dispensing worktables for intelligent manufacturing, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a base 1, a fixing mechanism 2, a cleaning mechanism 3 and a wiping mechanism 4 are included, the base 1 is provided with a fixing mechanism 2, the base 1 is provided with a cleaning mechanism 3, and the base 1 is provided with a wiping mechanism 4 .

[0029] First, people place the dispensing workbench on the fixing mechanism 2, and add enough cleaning agent in the cleaning mechanism 3, and then people can push the fixing mechanism 2 to the right, so that the fixing mechanism 2 drives the workbench to move to the right, and at the same time through the fixing The cooperation between the parts of the mechanism 2 makes the fixing mechanism 2 clamp the workbench, and then when the workbench moves to the bottom of the cleaning mechanism 3, people can open the cleaning mechanism 3, so that the cleaning agent in the cleaning...

Embodiment 2

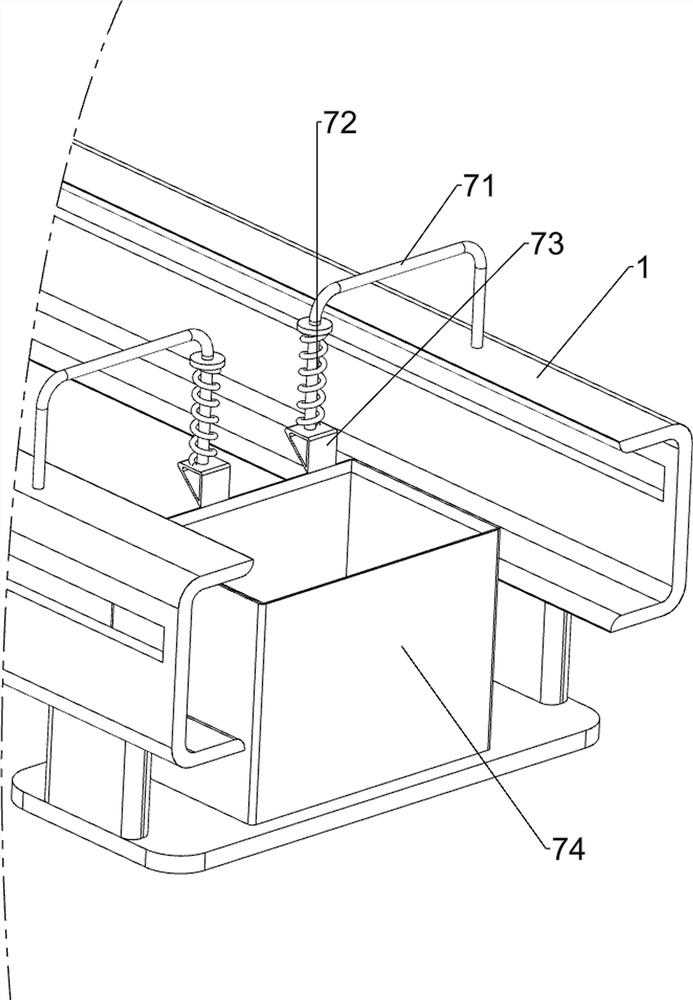

[0035] On the basis of Example 1, such as figure 1 , Figure 5 , Image 6 and Figure 7 As shown, it also includes a cleaning auxiliary mechanism 5, and the cleaning auxiliary mechanism 5 includes a second fixed rod 51, a third telescopic assembly 52, a first connecting rod 53, a fixed block 54, a connecting block 55, a top plate 56 and a push rod 57, basically The top of the left side of the seat 1 is symmetrically provided with a second fixed rod 51, the top of the second fixed rod 51 is provided with a third telescopic assembly 52, and a first connecting rod 53 is arranged between the third telescopic assembly 52. On the first connecting rod 53 A plurality of fixing blocks 54 are provided, and connecting blocks 55 are arranged on the valve 34, and the connecting blocks 55 cooperate with the fixing blocks 54. A top plate 56 is arranged between the two first sliding sleeves 21 on the rear side, and a top plate 56 is arranged on the first connecting rod 53. A push rod 57 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com