Connection structure, optical anti-shake module, camera device and electronic product

A connection structure and connection part technology, which is applied in the fields of electronic products, photographic devices, and connection structures, can solve the problems of low use value of cameras, high requirements for anti-shake motors, complex structure and process, etc., so as to improve optical anti-shake performance and realize The effect of miniaturization and process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

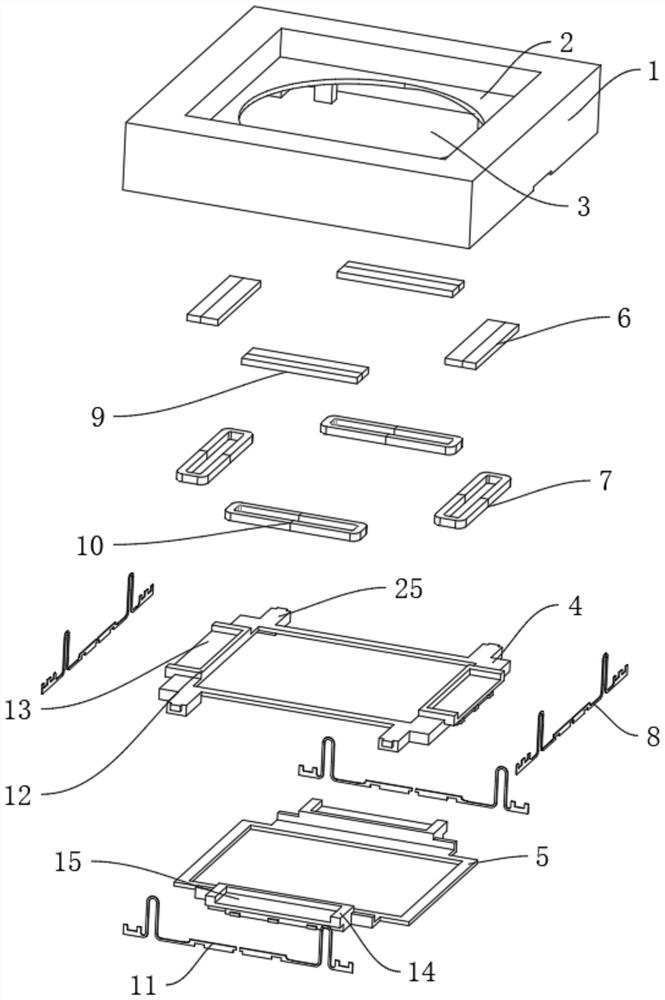

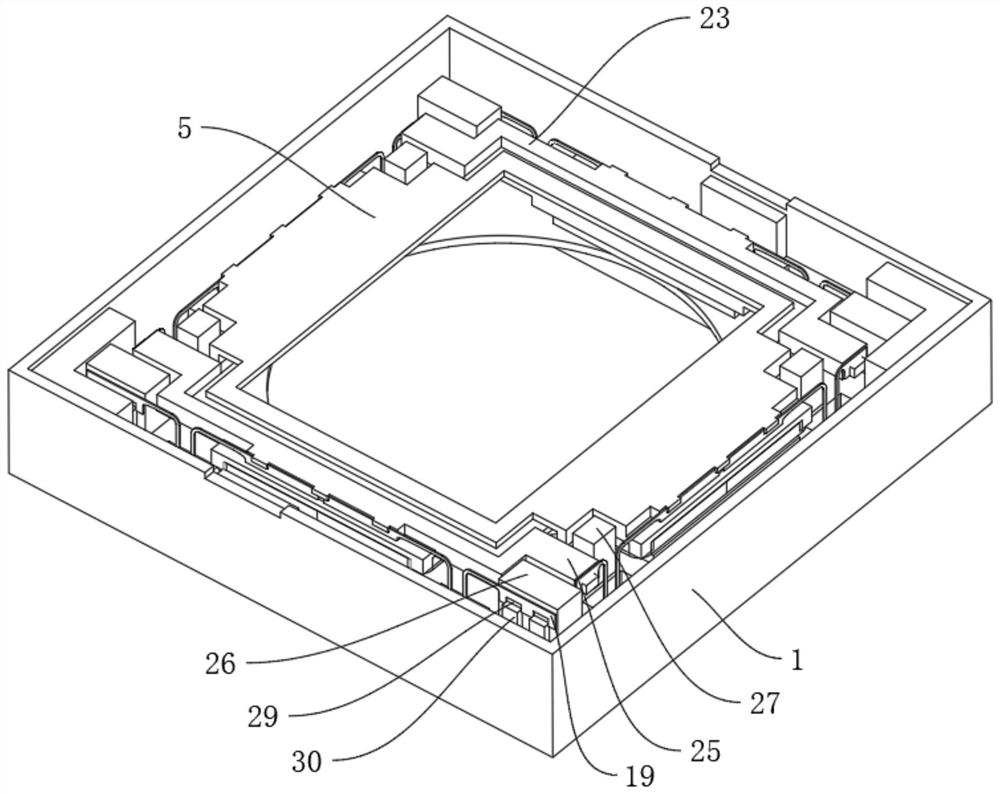

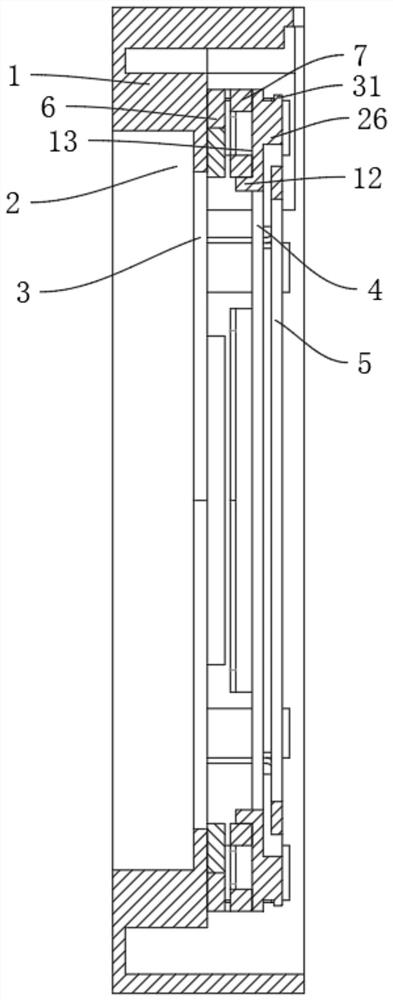

[0040] Embodiment 1: as Figures 1 to 8 As shown, a connection structure proposed by the present invention includes a casing 1, and a sinking groove 2 is opened on the surface of the casing 1, and the sinking groove 2 is located at the center of the casing 1, and the center of the sinking groove 2 is provided with a light-transmitting hole for light to irradiate the sensor. Hole 3.

[0041] A first bracket 4 and a second bracket 5 are installed in the inner cavity of the housing 1, and the first bracket 4 and the second bracket 5 are all arranged in a square shape, and the first bracket 4 and the second bracket 5 can move relative to the plane of the housing 1, And the moving direction of the first bracket 4 and the second bracket 5 is perpendicular to each other, and the first bracket 4 and the second bracket 5 are in close contact. The second bracket 5 is used for installing the sensor. The sensor can be installed on the end surface of the second bracket 5 away from the fir...

Embodiment 2

[0055] Embodiment 2, differs from Embodiment 1 in that: as Figure 9 As shown, in this embodiment, the second fixing portion 19 of the first spring 8 defines a second locking groove 29, and correspondingly, the housing 1 is provided with a locking block 30 corresponding to the second locking slot 29, and the locking block 30 is connected to the second locking slot 29. A limit block 26 is integrally formed.

Embodiment 3

[0056] Embodiment 3: An optical anti-shake module, having the connection structure described in Embodiment 1 or Embodiment 2, specifically, including the housing 1, the first bracket 4, and the second bracket 5 in Embodiment 1 or Embodiment 2 , a sensor is fixed on the surface of the second bracket 5 away from the shell 1, the sensor is used to receive the irradiated light, and realize the conversion of the optical signal into an electrical signal, and the second bracket 5 drives the sensor to translate to realize the optical anti-shake performance. The above-mentioned structure can facilitate the installation of various AF motors in the optical anti-shake module and improve the optical axis accuracy of the AA process of the module, which can effectively reduce the cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com