A clamping device for precision mold production and processing

A technology of precision molds and clamping devices, applied in the direction of workbenches, manufacturing tools, etc., can solve problems such as difficult operation, single applicability, and weak clamping, and achieve stable clamping effect, good clamping effect, and versatility strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

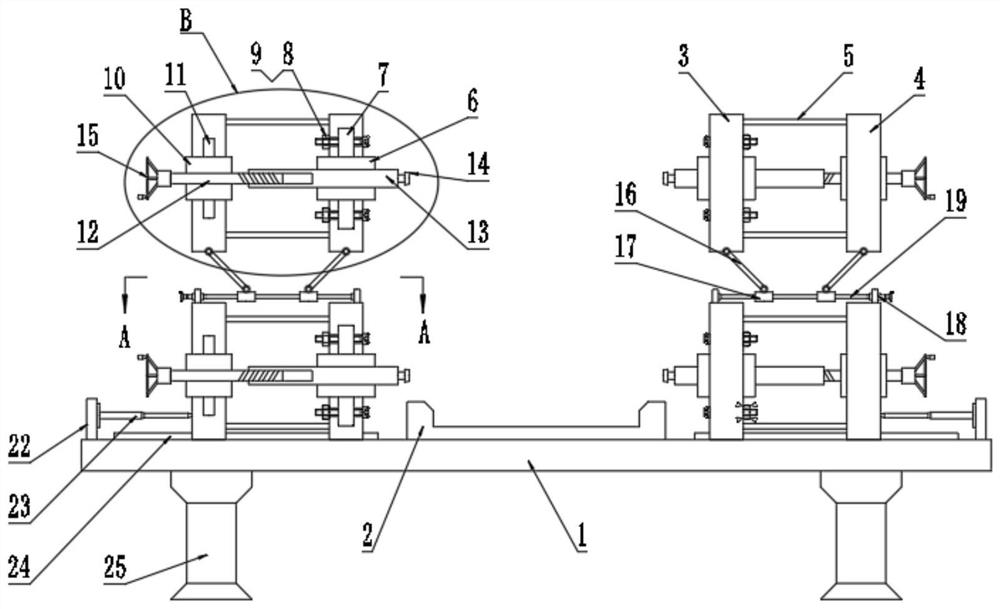

[0024] see figure 1 In the embodiment of the present invention, a clamping device for precision mold production and processing includes a processing platform 1 and a supporting concave plate 2, the supporting concave plate 2 is fixedly connected and arranged in the middle of the top of the processing platform 1, and the supporting concave plate 2 Clamping structures are arranged on both sides of the structure, and multiple sets of clamping structures are evenly distributed in the longitudinal direction. Lifting structures are set between two adjacent sets of clamping structures, and the lifting structures are used to adjust the clamping structures at different positions. Height, used for clamping according to the unevenness of the actual mold surface and the position of the mold to be processed.

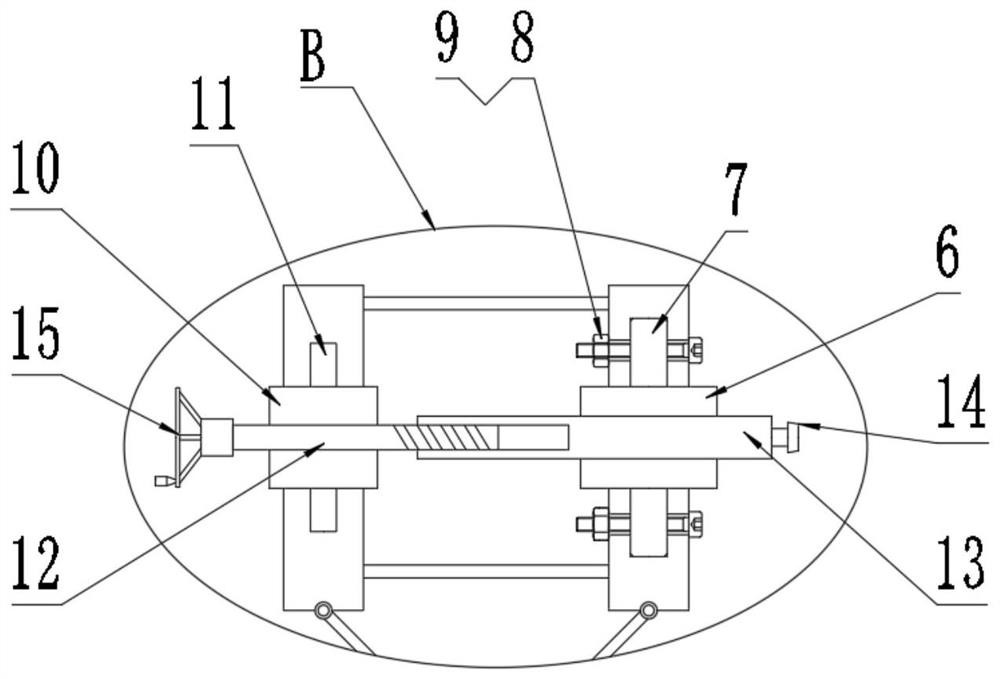

[0025] see Figure 1~2 , the clamping structure includes an inner vertical plate 3, an outer vertical plate 4, a threaded rod 12 and a screw sliding sleeve 13, the outer sliding blo...

Embodiment 2

[0028] see figure 1 and Figure 4 , in an embodiment of the present invention, a clamping device for precision mold production and processing, the outer vertical plate 4 includes an outer plate body 41, an outer chute 42 and an outer connecting chute 43, the two sides of the outer chute 42 All are provided with outer connecting chute 43, and the outer stabilizing slider 11 is arranged in sliding connection in the outer connecting chute 43, and the outer stabilizing slider 11 is fixedly connected with the outer slider 10, and the outer slider 10 and the outer slider 10 are fixedly connected. The outer chute 42 is slidably connected.

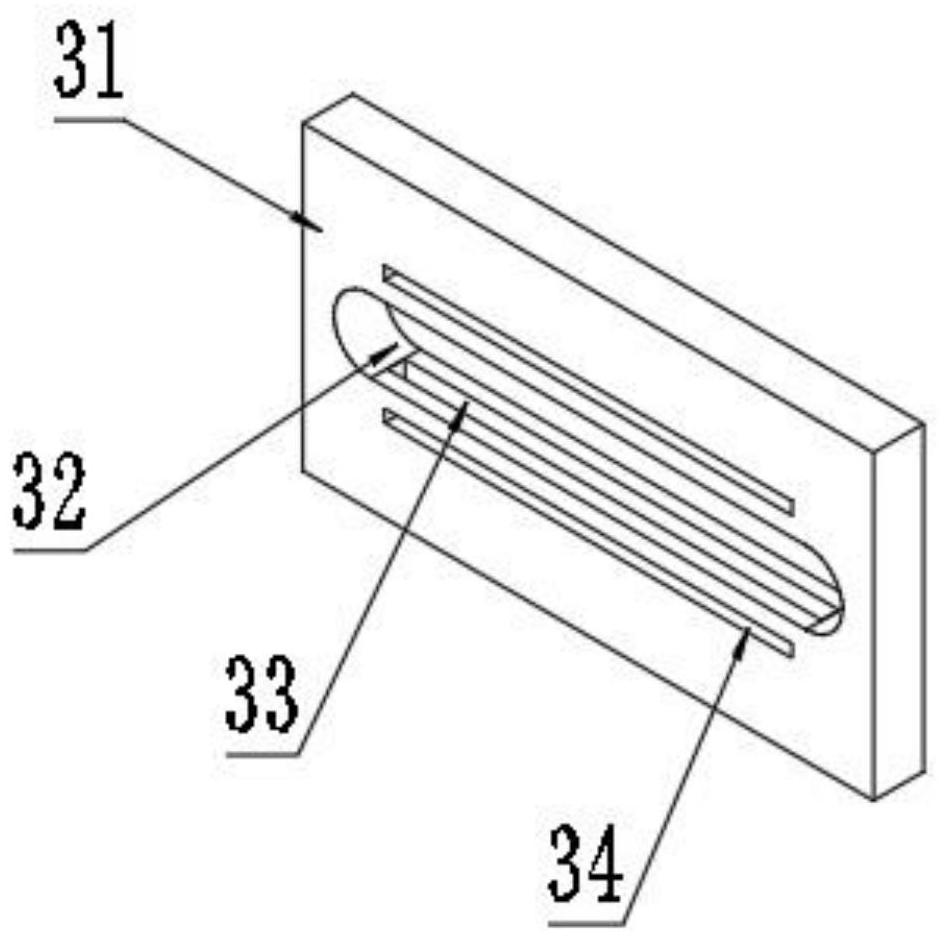

[0029] see Figure 1~3, the inner vertical plate 3 includes an inner plate body 31 and an inner chute 32, the inner chute 32 is set through the two sides of the inner plate body 31, and both sides of the inner chute 32 are provided with an inner connecting chute 33, both sides of the inner connecting chute 33 are provided with bolt installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com