Flexible linear material of liquid fluid, liquid fluid composite yarn forming method and application

A fluid material, flexible thread technology, applied in the direction of continuous winding spinning machine, yarn, spinning machine, etc., can solve the problems of difficult carding and collection of liquid fluid, inability to perform spinning and weaving processing, etc., to achieve easy textile molding , the effect of excellent appearance and feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Yarn forming with built-in non-Newtonian fluid

[0046] The special feature of non-Newtonian fluid is that it has viscosity, and the viscosity will change. When it is under pressure, it will produce viscosity, and when the pressure continues to increase, the viscosity will continue to increase. It becomes a solid, and the hardness of this solid is still very high. However, non-Newtonian fluids are difficult to compound into yarns, cannot be spun into flexible cloth-like structures, and cannot guarantee the uniform dispersion and stable combination of non-Newtonian fluids, resulting in the decline of the impact resistance of non-Newtonian fluids themselves.

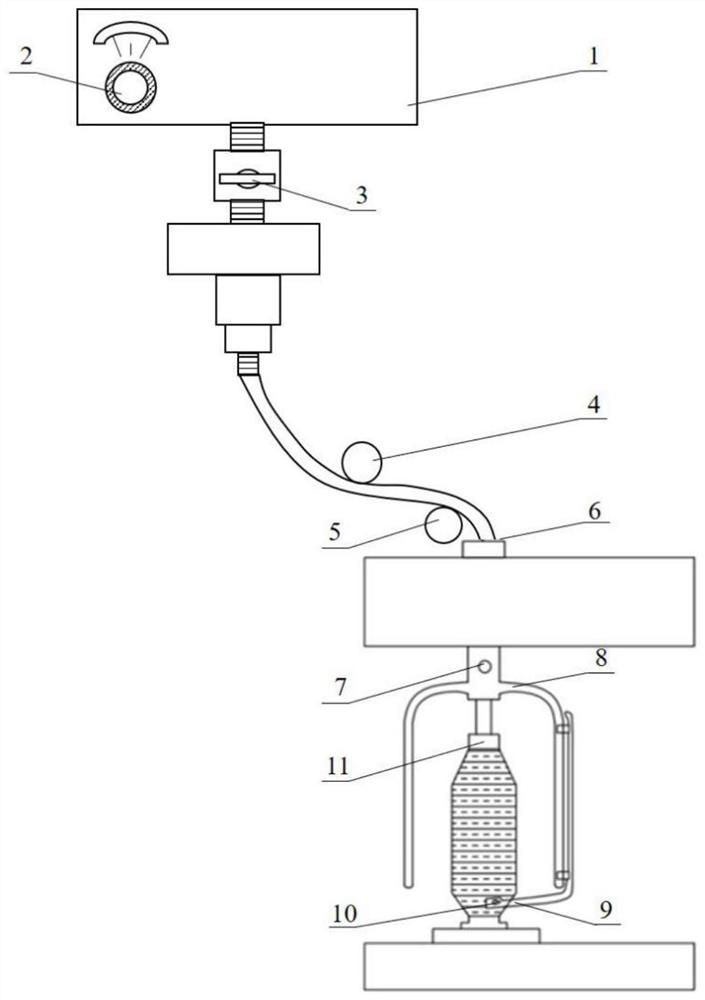

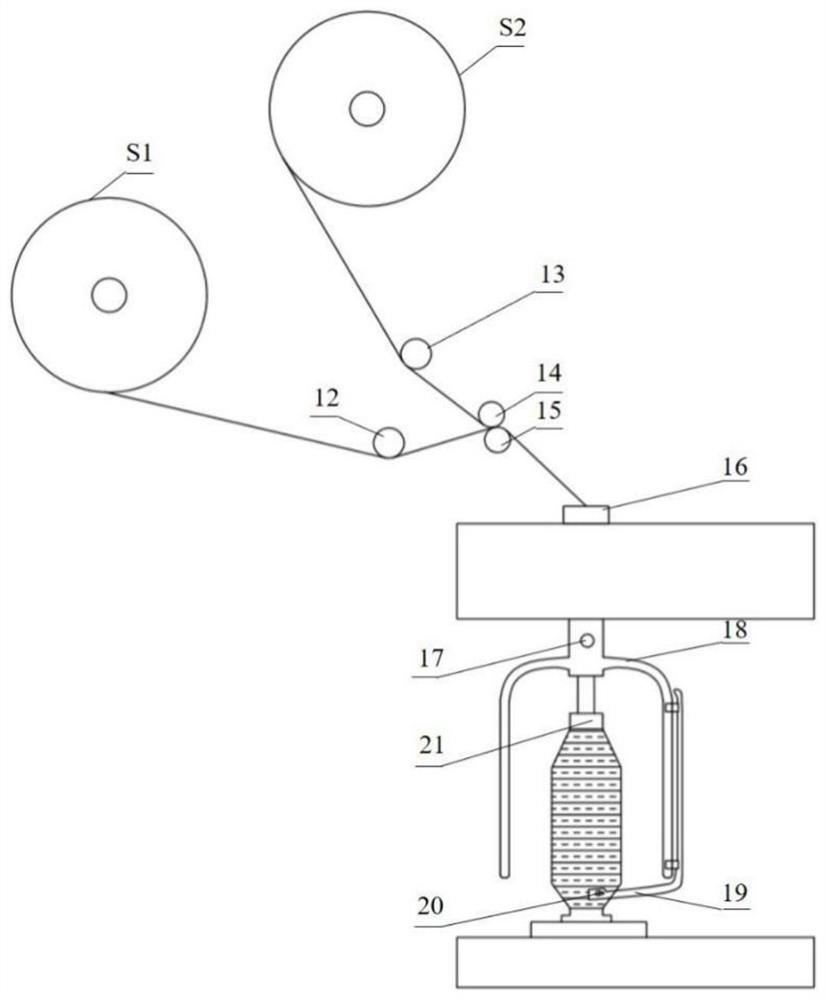

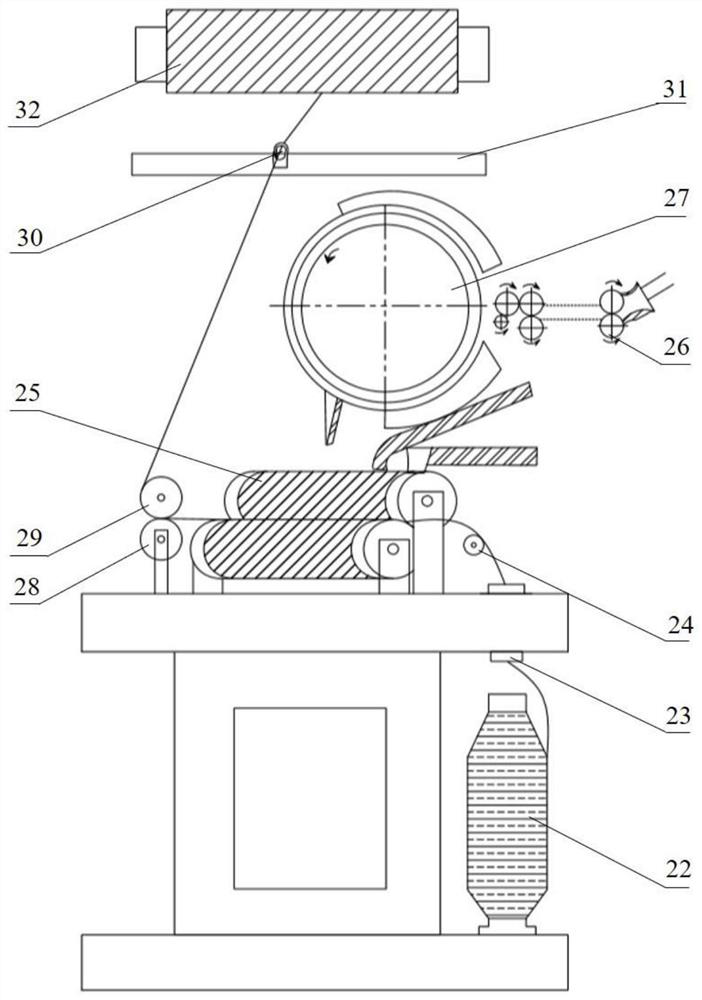

[0047] see Figure 1-4 As shown, a flexible linear material of a liquid fluid adopts the yarn forming method of a built-in non-Newtonian fluid in the present invention, and the specific steps are:

[0048] A. Built-in Encapsulation of Fluid Materials

[0049] see figure 1 As shown, the non-Newtonian fluid materi...

Embodiment 2-3

[0059] A liquid flexible linear material. Compared with Embodiment 1, the difference is that the material type of the built-in fluid material is changed. The rest of the steps are roughly the same as Embodiment 1, and will not be repeated here. The types of fluid materials corresponding to each embodiment are shown in Table 1.

[0060] The material type of the built-in fluid of the liquid-fluid composite yarn prepared in Example 2-3 of Table 1

[0061] Example Material type Example 2 distilled water Example 3 cooking oil

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com