Fabricated floor structure

A prefabricated and floor-slab technology, applied in the direction of floor slabs, building components, building structures, etc., can solve the problems of increased transportation of prefabricated panels, difficulty in installation, and brittle failure of laminated panels, so as to reduce construction costs, reduce weight, and improve connections. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

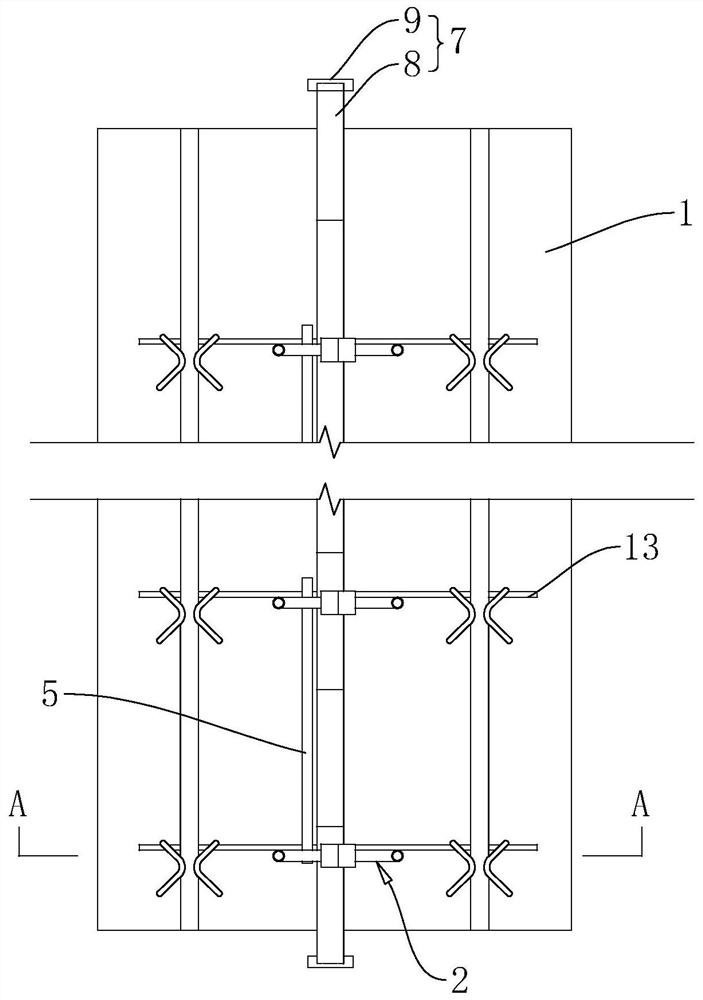

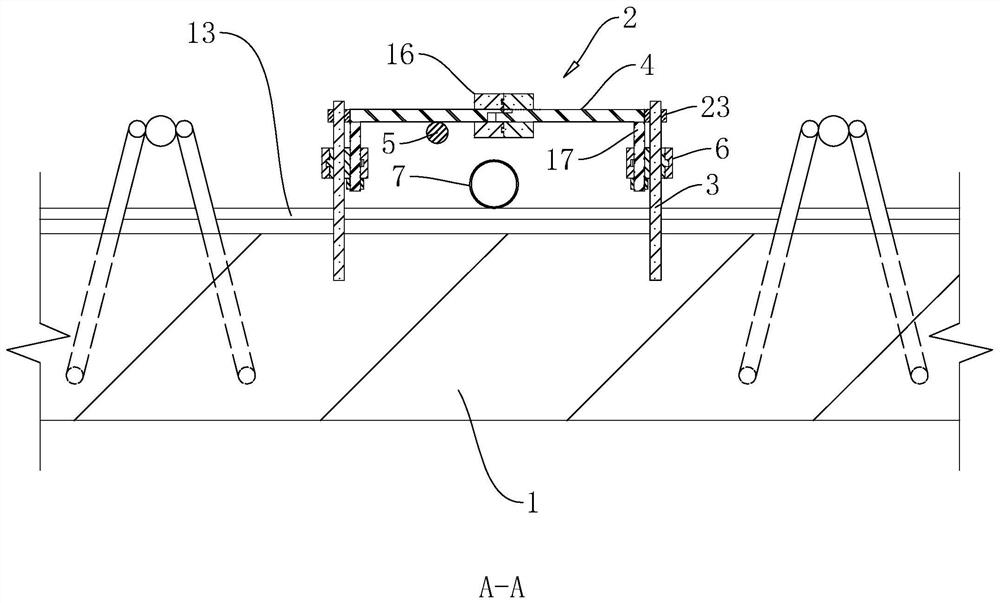

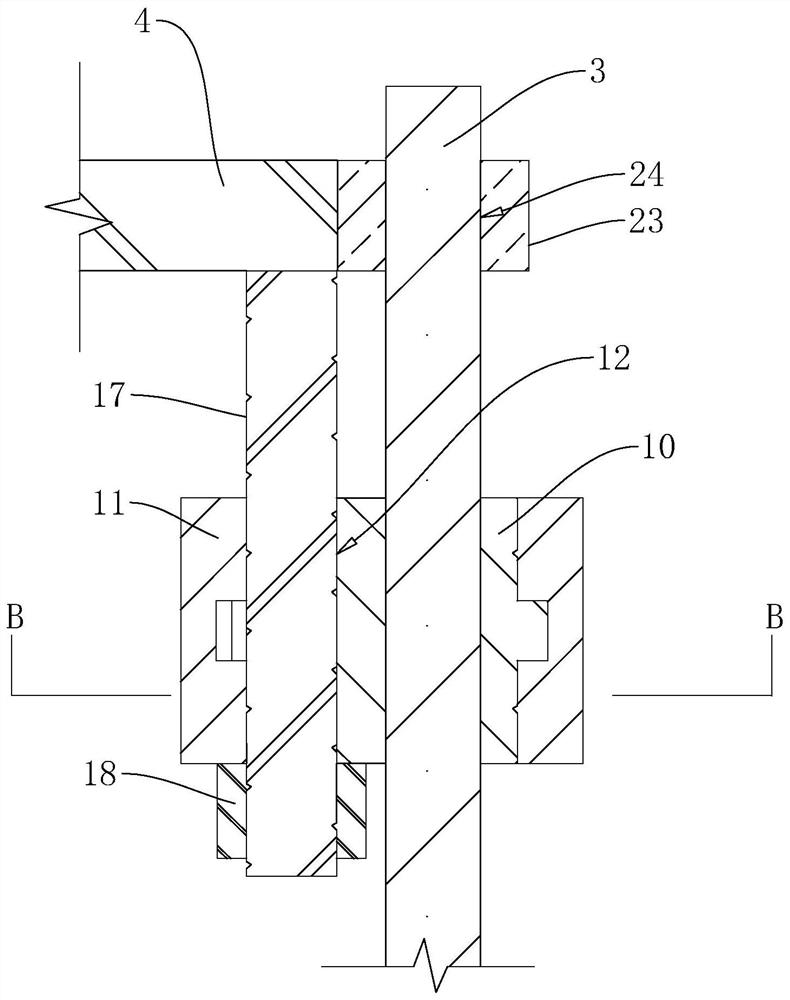

[0036] The following is attached Figure 1-6 The application is described in further detail.

[0037] The embodiment of the present application discloses a prefabricated floor structure. refer to figure 1 , the prefabricated floor structure includes a prefabricated slab 1 connected to a support frame 2 on the upper surface of the prefabricated slab 1 . The prefabricated slab 1 is in the shape of a rectangle, and several steel bar trusses protruding from the upper surface of the prefabricated slab 1 are formed on the prefabricated slab 1. In the implementation of this application, two steel bar trusses are arranged at intervals along the width direction of the prefabricated slab 1. The length of the steel bar truss The direction is set parallel to the length direction of the prefabricated slab 1 .

[0038] In the implementation of this application, there are two support frames 2 parallel to the length direction of the steel bar truss at intervals, each support frame 2 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com