Assembly type tent support

A prefabricated tent technology, applied in the field of tents, can solve problems such as no functional partitions, lack of strength of tent brackets, lack of support and reinforcement structures, etc., to improve structural strength and stability, convenient disassembly, storage and transportation, and joint connection The effect of software optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

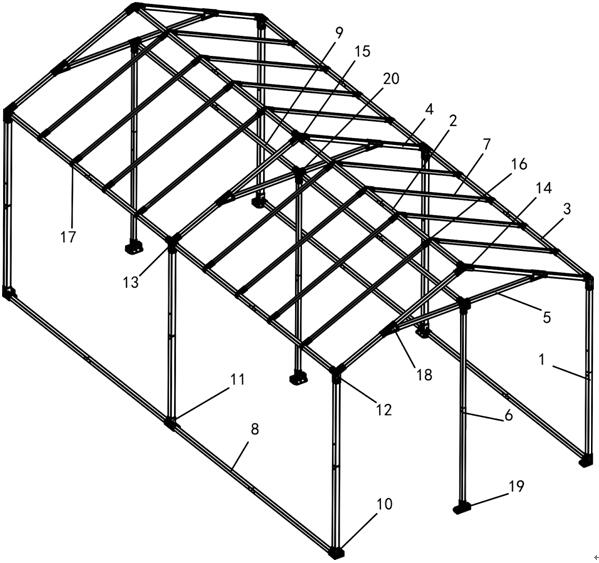

[0030] Such as figure 1 As mentioned above, the assembled tent support provided by the present invention has a rectangular tent support structure with a long side of 5.8 meters and a short side of 3.1 meters as a whole. The group includes three supporting vertical bars 1 evenly arranged, and the lower ends of the supporting vertical bars on one side are respectively connected with butt-joint bottom corner connectors 10 and bottom mid-connectors 11 to connect and fix with the ground, and the bottom corner connectors and the bottom Two side bottom bars 8 are connected between the middle connectors, wherein the conical roof assembly includes a first transverse bar set arranged on the middle spine, respectively arranged on both sides of the first transverse bar set and connected with the vertical support The second transverse rod group connected to the rod group, the longitudinal rod group that is uniformly distributed along the axial direction of the first transverse rod group an...

Embodiment 2

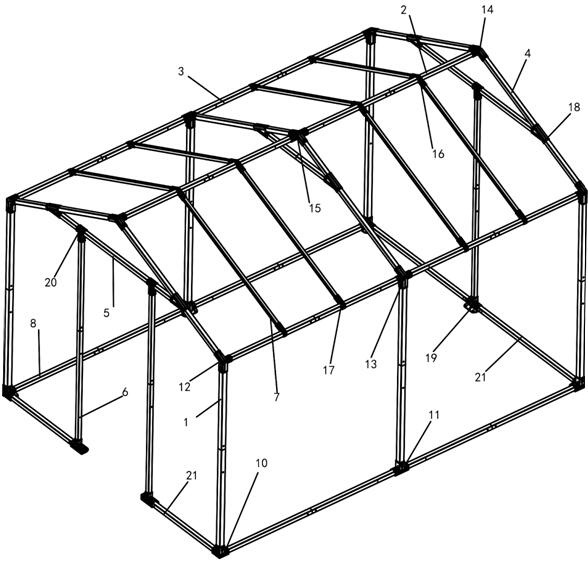

[0036] Such as figure 2 As stated, the assembled tent support provided by the present invention has a rectangular tent support structure with a long side of 4.2 meters and a short side of 3.1 meters as a whole. Compared with the assembled tent support of Implementation 1, six support vertical bars 1, Four side bottom bars 8, two first transverse bars 2, four second transverse bars 3, six longitudinal bars 4, and three docking bars 5, but the overall size of the second embodiment is further reduced, compared with that of the first example The main difference is that in this embodiment, four adjustment rod groups are connected to the top of the conical roof assembly, which are evenly distributed on the top surface of the shed formed by three sets of longitudinal rod groups, and the butt joint in the middle of the shed The rod 5 is set as a short rod, and the upper end is not provided with a partition vertical rod, and two partition vertical rods 6 are arranged downward on the o...

Embodiment 3

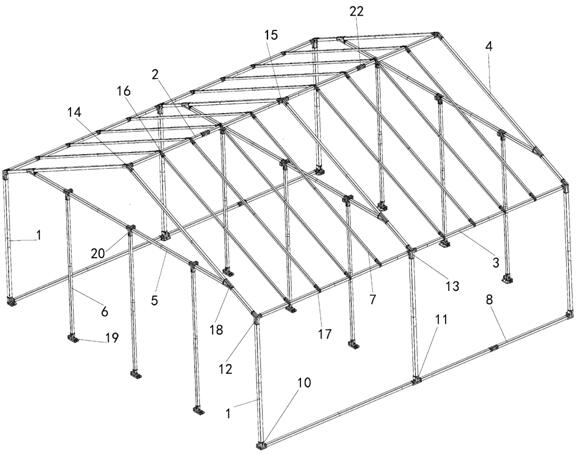

[0039] Such as image 3 , Figure 4 As mentioned above, the assembled tent frame provided by the present invention is set up as a square tent frame structure with a side length of 5.8 meters. The partition function rod group that can be connected and set at the 5 ends of the docking rod includes three partition vertical rods, and the partition vertical rods at the 5 ends of the three docking rods can be arranged in parallel or staggered, which has a larger tent construction space, and in specific use At the same time, the quantity and corresponding positions of the partition vertical bar 6, the gable bottom bar 21, and the third transverse bar 9 can be adjusted and changed according to actual needs, and can be adapted to various needs in different situations.

[0040] In practical application, with image 3 Based on the structure, the conical ceiling assembly and the end faces of the two vertical support assemblies can be covered, and a circular one-meter-line isolation belt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com