Piston type multi-stage high-pressure gas switch

A high-pressure gas switch and piston-type technology, which is applied to the valve's device for absorbing fluid energy, valve lift, valve details, etc., can solve problems such as failure to open normally, affecting the launch control of the launch device, and insensitive control of ordinary solenoid valves. Achieve the effect of improving launch control and improving launch control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

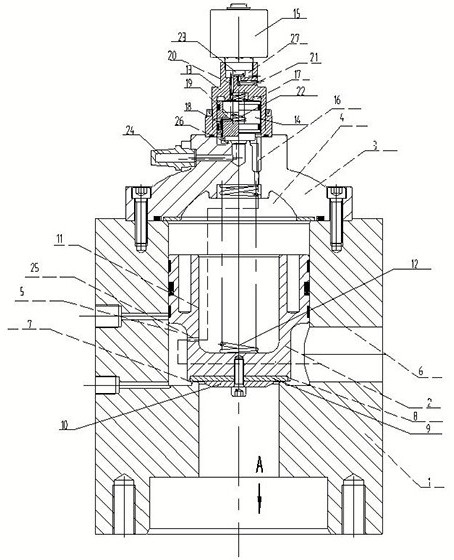

[0019] see figure 1 , serial numbers in the figure: 1 is the valve body, 2 is the valve core, 3 is the valve cover, 4 is the upper valve cavity, 5 is the air passage, 6 is the air inlet, 7 is the convex edge, 8 is the groove, and 9 is the seal Pad 1, 10 is the pressure plate, 11 is the blind hole 1, 12 is the spring 1, 13 is the connecting body, 14 is the piston, 15 is the solenoid valve, 16 is the air hole, 17 is the piston hole, 18 is the L-shaped air hole, 19 Step-shaped blind hole 2, 20 is air outlet 1, 21 is air outlet 2, 22 is spring 2, 23 is an electromagnetic armature, 24 is a large hole vent valve, 25 is through hole 1, 26 is a protrusion, 27 is an upper cavity.

[0020] A piston-type multi-stage high-pressure gas switch of the present invention includes a valve body 1, a valve cover 3 fixed and installed above the va...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap