Grinding machine applied to magnesium alloy diaphragm

A technology of grinding machine and magnesium alloy, which is applied to grinding machines, abrasive belt grinders, grinding drive devices, etc., can solve the problems that the thickness and surface roughness of the final grinding piece can not meet the specifications of medical equipment products, and achieve a simple and practical structure. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

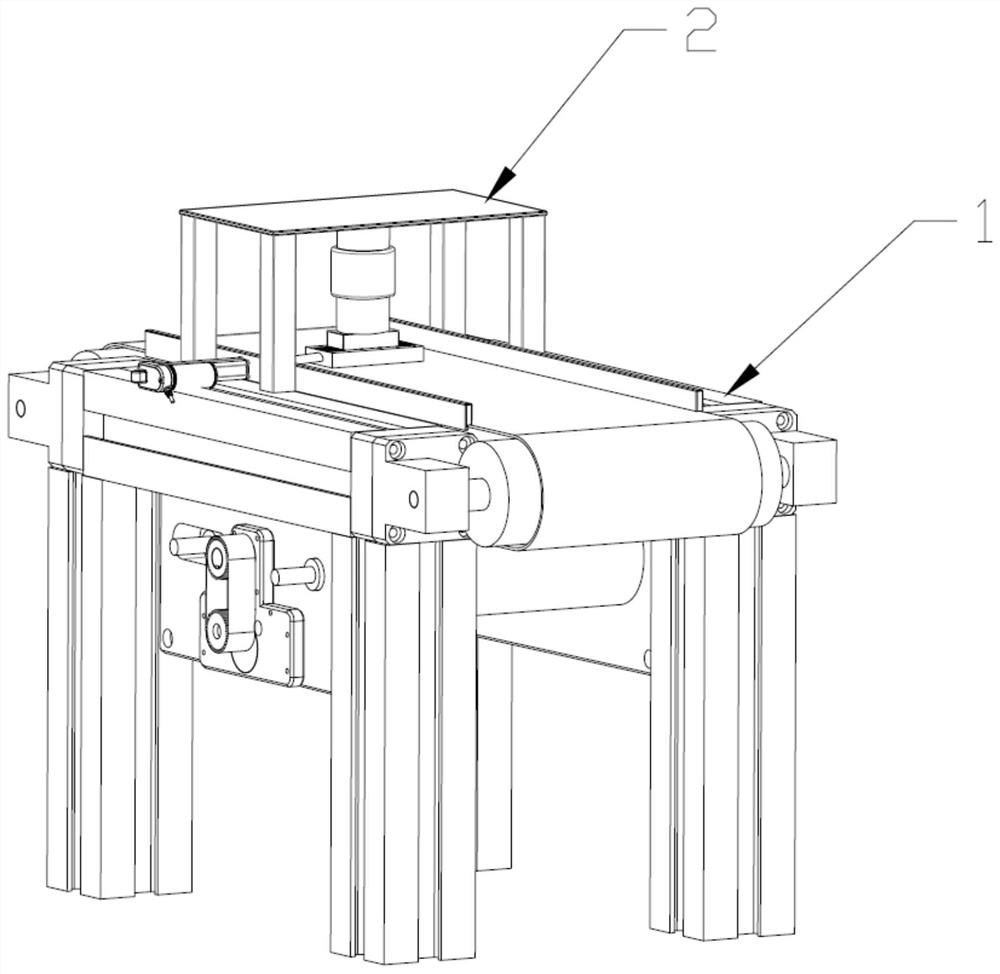

[0026] Such as figure 1 As shown, the embodiment of the present invention provides a grinding machine applied to magnesium alloy diaphragms, including a transmission mechanism 1 and a grinding mechanism 2, the transmission mechanism 1 is used to transmit sandpaper, and the grinding mechanism 2 is arranged to be installed on the transmission mechanism 1, And contact with the transmission mechanism 1.

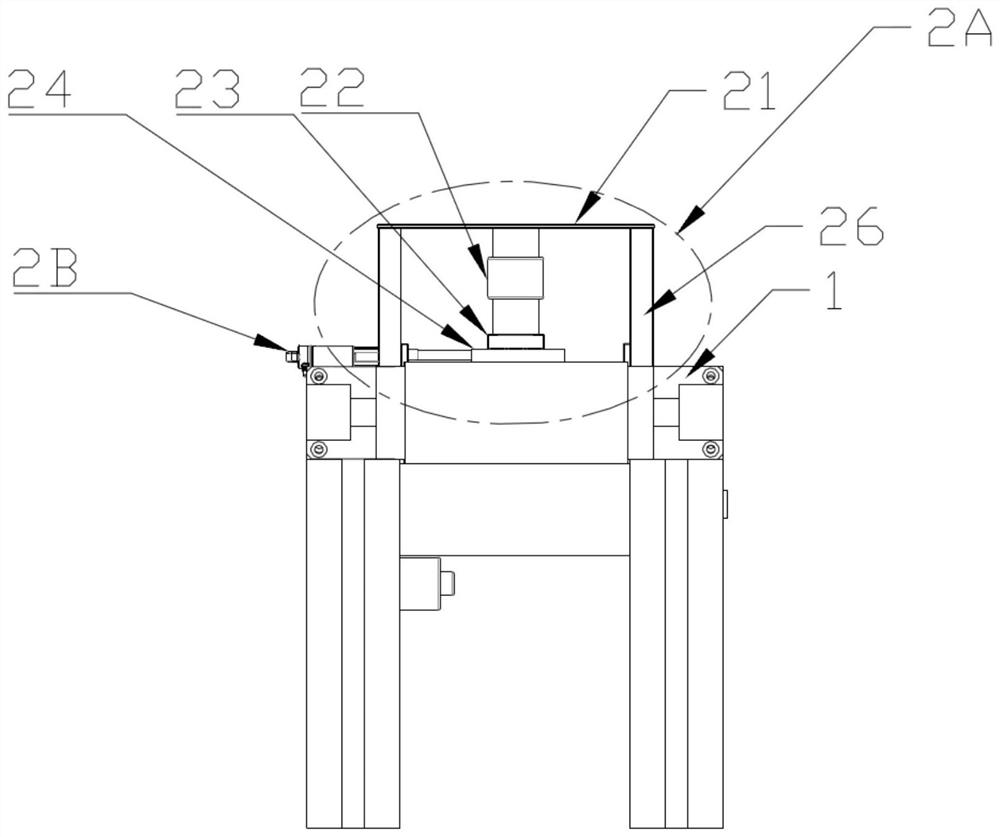

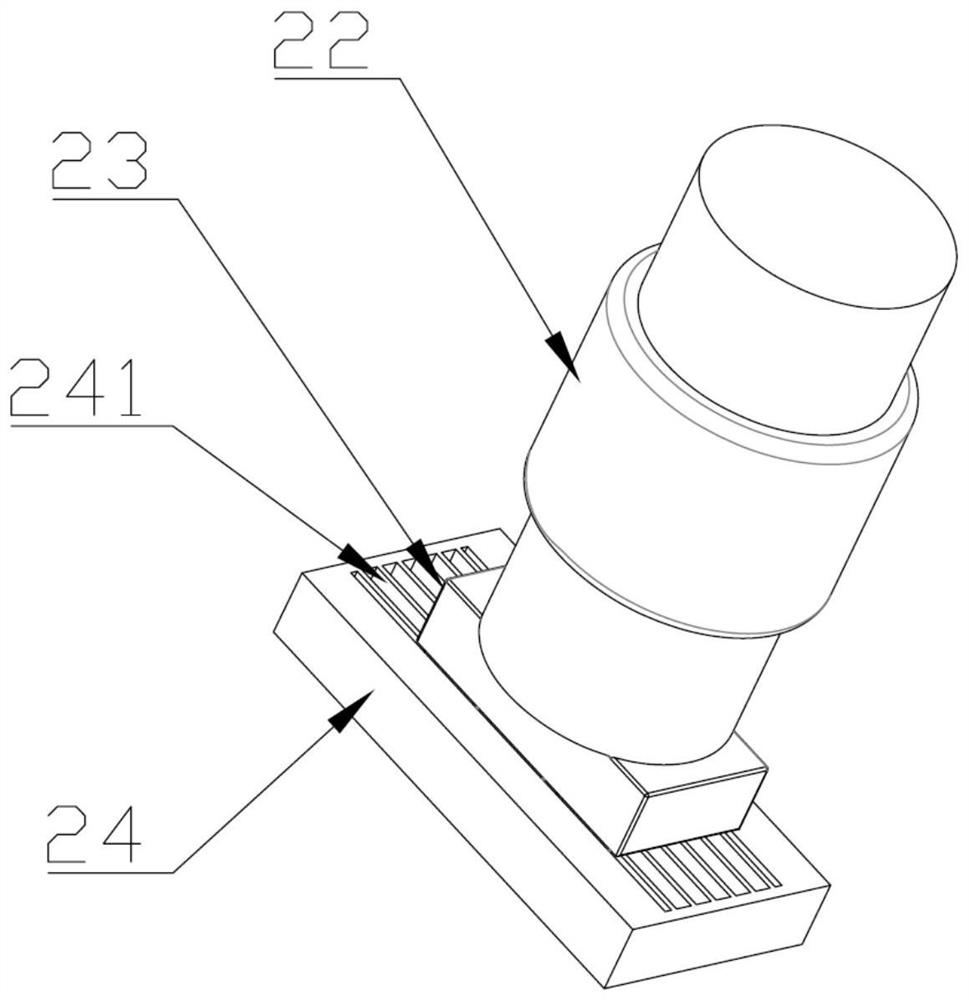

[0027] Specifically, such as figure 2 As shown, the grinding mechanism 2 includes a driving device 2B, a grinding mechanism bracket 26 and a grinding tool device 2A, the driving device 2B is connected to the grinding tool device 2A, and drives the grinding tool device 2A to move, and the grinding tool device 2A is installed on the grinding mechanism bracket 26 , the grinding mechanism bracket 26 is fixed on the transmission mechanism 1 . The driving device 2B is arranged on the transmission mechanism 1, and the driving device is set as an electric push rod, including a motor a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com