Lock hook grinding notch clamp and using method thereof

A locking hook and grinding technology, which is applied in the direction of grinding workpiece supports, etc., can solve the problems affecting the production progress and product quality of the workshop section, inconvenient storage and handling, and affecting the dimensional accuracy of parts, etc., achieving a breakthrough in processing concepts, simple structure, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

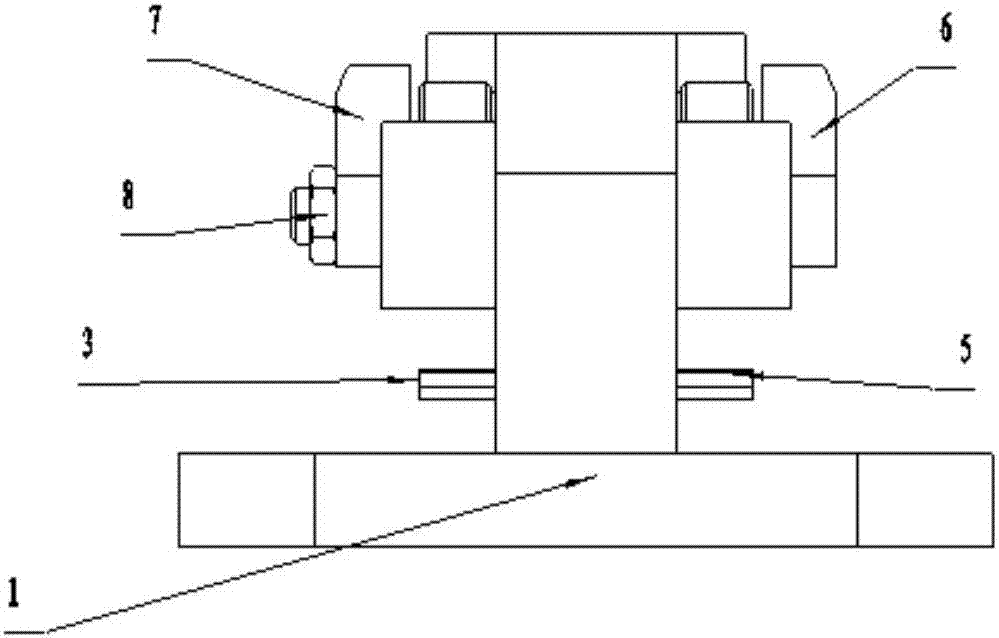

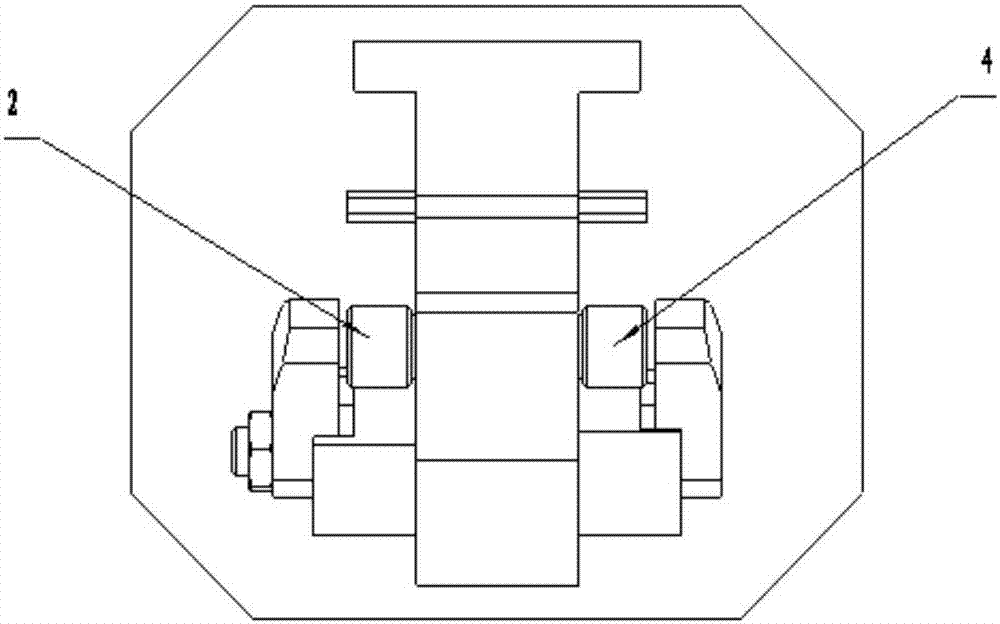

[0016] 1. Check the working status of the universal grinding machine, replace and install the grinding wheel that meets the processing conditions.

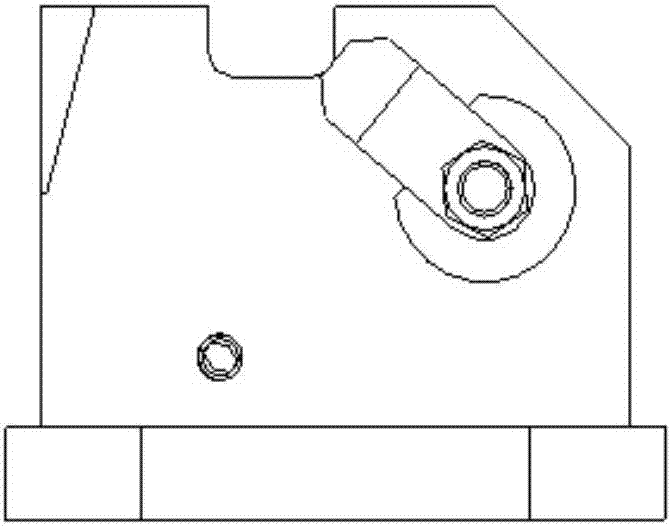

[0017] 2. Put the hook grinding notch jig flat on the working table of the universal grinder, ensure that the main body of the jig is parallel to the working table of the grinding machine, and use the pressure plate to compress the jig.

[0018] 3. Install the two locking hooks into the positioning pins on both sides of the fixture respectively, with the notches facing upward.

[0019] 4. Press the lock hook parts with the pressure plate, and tighten the No. 8 nut.

[0020] 5. Grinding the notch: Grinding the notch, realizing the processing of the whole notch by adjusting the workbench, using the manufacturing precision of the fixture itself to ensure the parallelism (0.02 / 8) of the notch relative to the large positioning hole of the lock hook.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com