A mixed working medium refrigeration system and control method for rapid start-up of a low-temperature preservation box

A refrigeration system and low-temperature storage technology, which is applied in the field of refrigeration and low temperature, can solve the problems of complex system, non-normal condensation of mixed working medium, large volume, etc., and achieve the effect of simplifying the refrigeration system, improving the startup speed and the safety of the system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

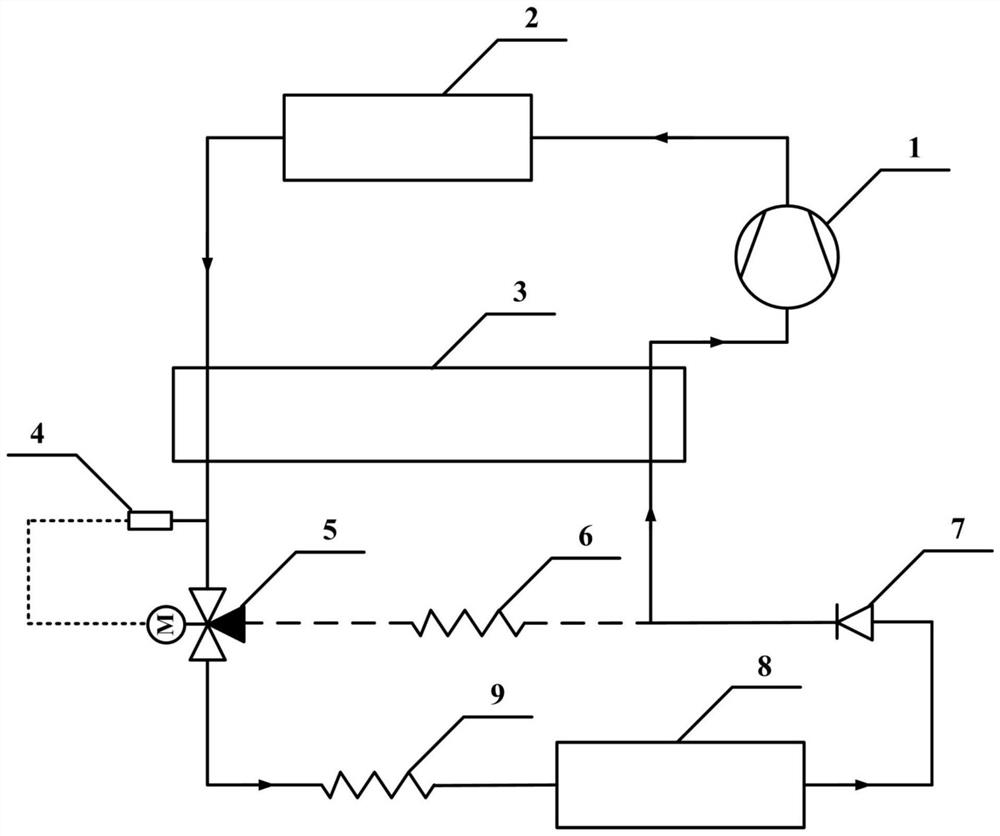

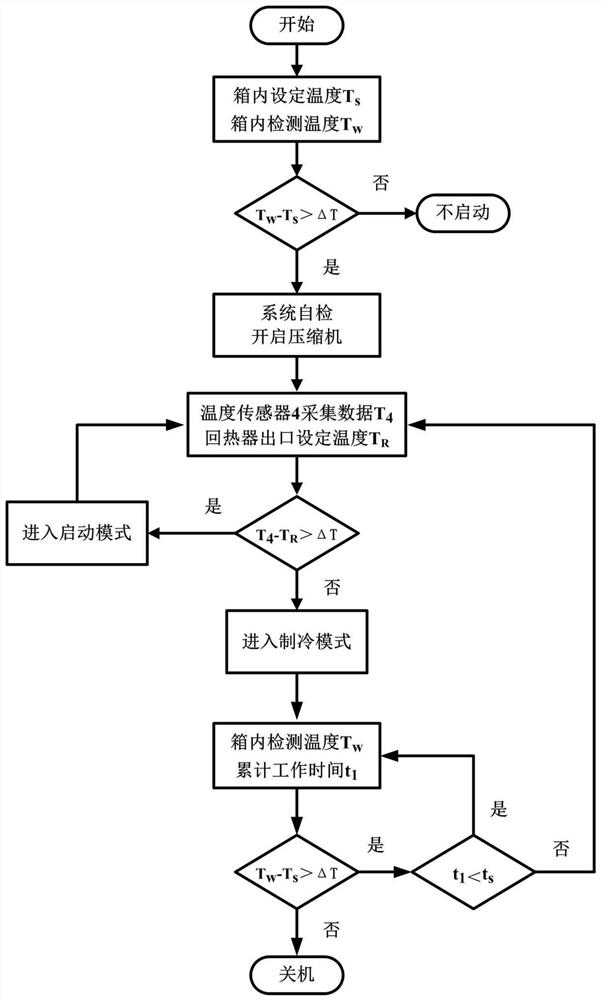

[0018] The mixed working medium refrigeration system of the low temperature preservation box has two working modes, including start-up mode and refrigeration mode, and the specific working method is as follows:

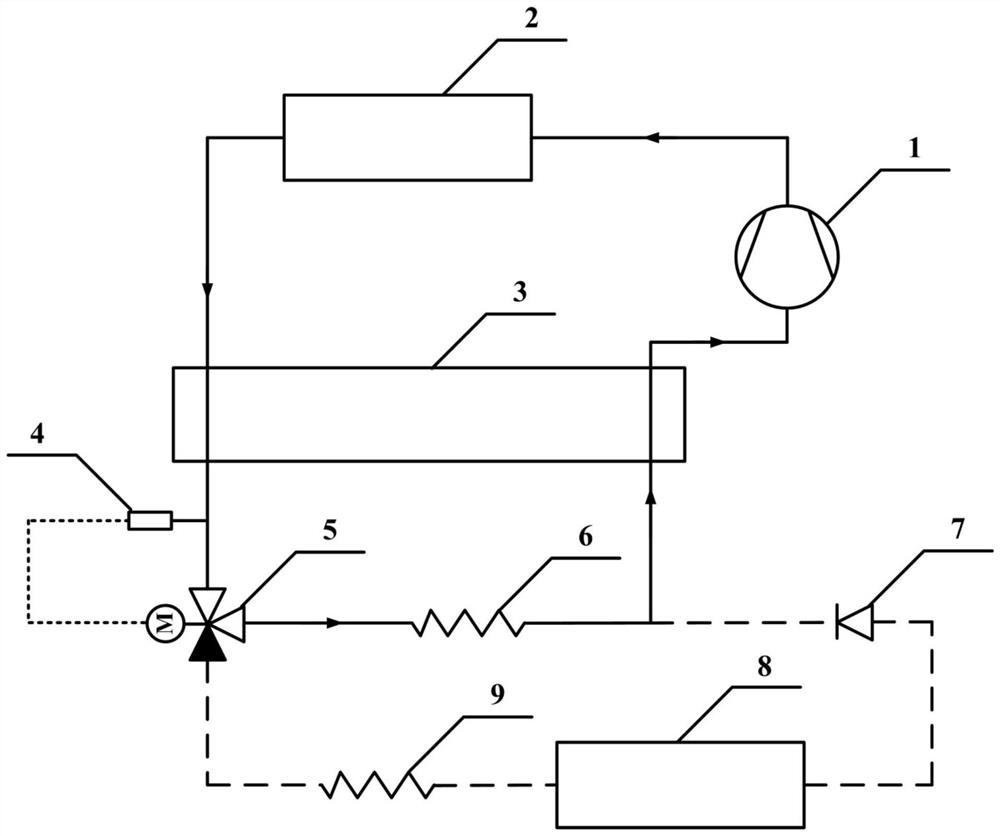

[0019] (1) Start mode

[0020] Such as figure 1 As shown, the present invention provides a mixed working medium refrigeration system for quick start-up of a low-temperature storage box. In the start-up mode, it includes a compressor 1, a condenser 2, a regenerator 3, a temperature sensor 4, and a two-position three-way solenoid valve 5 , a short capillary 6, a one-way valve 7; the high-pressure gaseous mixed working medium at the outlet of the compressor 1 is cooled in the condenser 2 into a gas-liquid two-phase mixed working medium; this part of the two-phase mixed working medium enters the regenerator 3 Afterwards, it will be further condensed, but due to the high refrigeration temperature in the start-up stage, the regenerator cannot completely condense the mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com