A test system and method for calculating the friction coefficient of inclined roller friction disc

A technology of friction coefficient and friction disc, which is applied in the field of test coefficient parameter measurement system, can solve the problems of severe wear, long-term replacement, and less research and achievements of inclined roller friction discs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

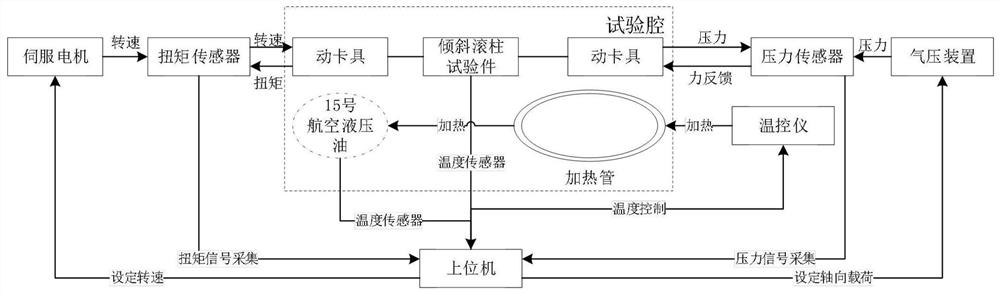

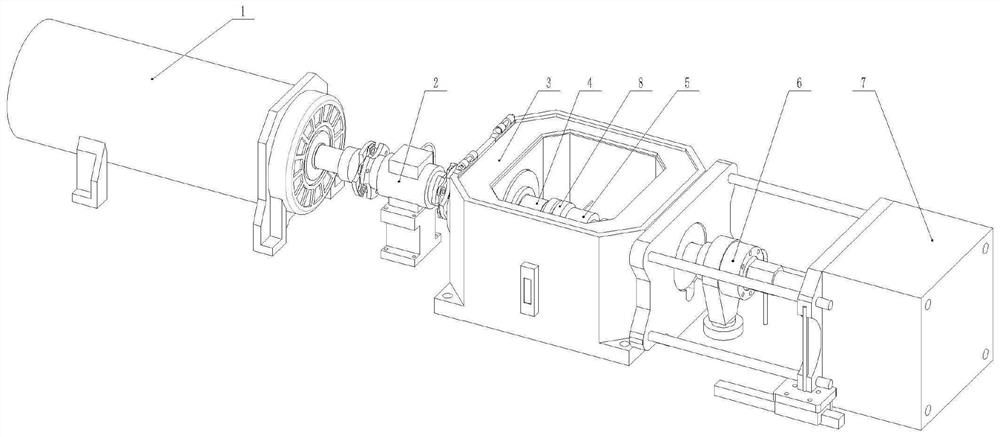

[0048] A test system and method for obtaining the friction coefficient of an inclined roller friction disc, comprising a servo motor 1, a torque sensor 2, a test chamber 3, a moving fixture 4, a static fixture 5, a pressure sensor 6, an air pressure device 7, Composed of an inclined roller test piece 8, the servo motor 1 provides a speed signal to drive the torque sensor 2, the torque sensor 2 transmits the speed parameter to the moving fixture 4, and the pneumatic device 7 provides a pressure signal to The pressure sensor 6, the moving fixture 4 and the static fixture 5 are all installed in the test chamber 3, and the moving fixture 4 and the static fixture 5 will tilt the roller test piece 8 caught in the middle;

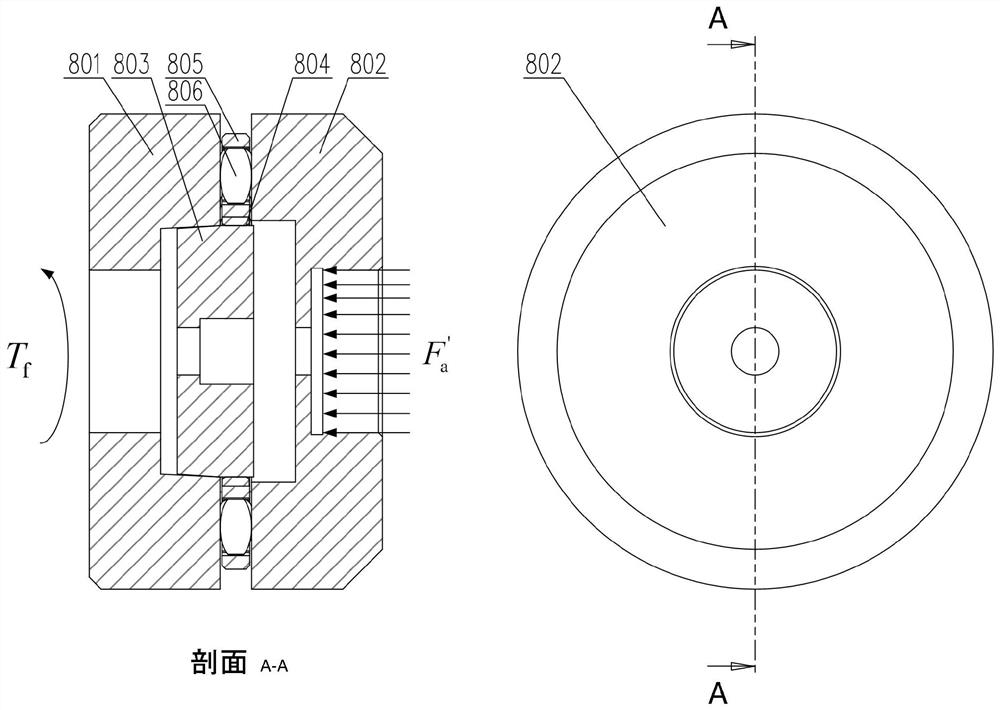

[0049] The inclined roller test piece 8 is composed of a dynamic friction disc 801, a static friction disc 802, an inclination fixing column 803, a copper sleeve 804, a cage 805 and a cylindrical roller 806. The torque sensor 2, the dynamic Fixture 4, the dynamic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com