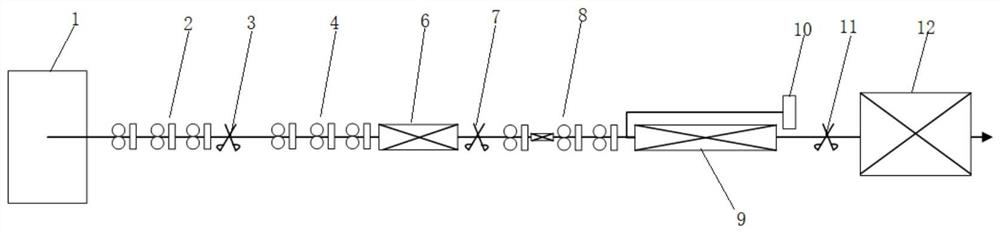

Bar Controlled Rolling Controlled Cooling Device and Technology

A technology of controlled rolling and controlled cooling, bar, applied in workpiece cooling devices, manufacturing tools, metal rolling, etc., can solve the problems of tempered martensite easily generated on the surface of steel bars, inaccurate control of cooling temperature, etc., to achieve high quality And the best low cost, convenient and practical replacement, simple and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

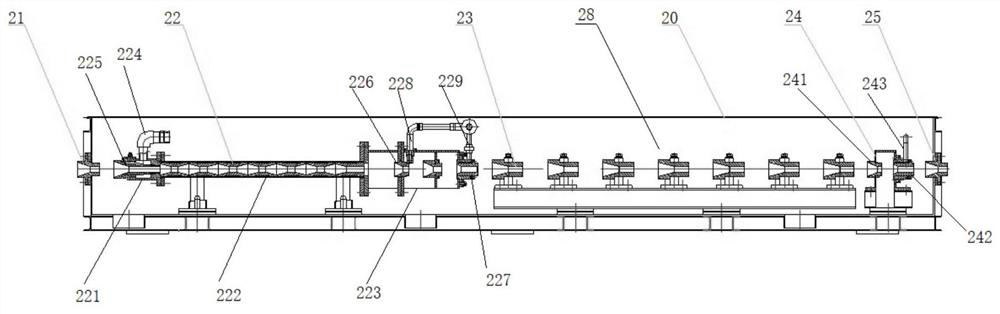

[0028] Below in conjunction with the accompanying drawings, the specific embodiments of the bar controlled rolling and controlled cooling device and process of the present invention are described in detail. Book

[0032] The cooler 22 is composed of a water inlet section 221, a turbulent flow pipe 222 and a water outlet section 223. Referring to Figure 4, the water inlet section 221 adopts screw

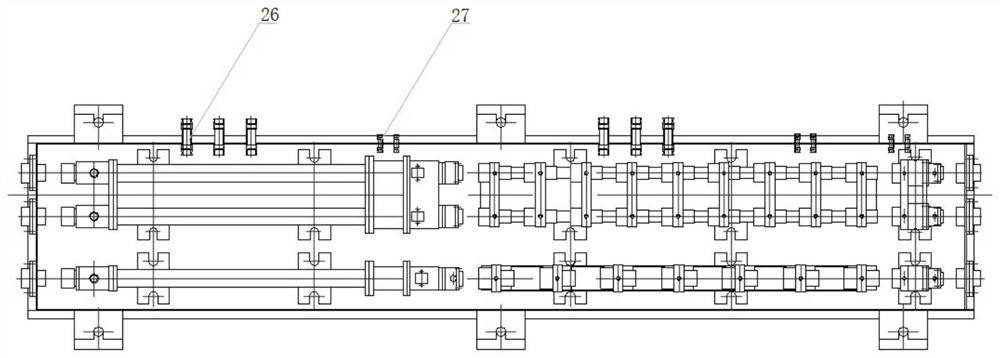

[0034] Referring specifically to FIG. 5, the slow cooling tube group 23 has a plurality of air jets 28 arranged along the rolling linear direction. jet 28

[0036] The front guide 231 and the rear guide 233 are respectively detachable through the fixing part and the jet base 232 through bolts

[0039] The water intercepting nozzles 227 and the water catching nozzles 242 described above in the present invention can all use the jets described above.

[0042] Under specific circumstances, the fixed thermometer is fixed with the frame 101 through the fixed support 112. Mobile Thermometer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com