Modular Roof Structures for Rail Vehicles

A rail vehicle and modular technology, applied in the field of rail vehicles, can solve the problems of complex roof installation process and difficult installation, and achieve the effects of avoiding uneven gaps, reducing workload and shortening operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

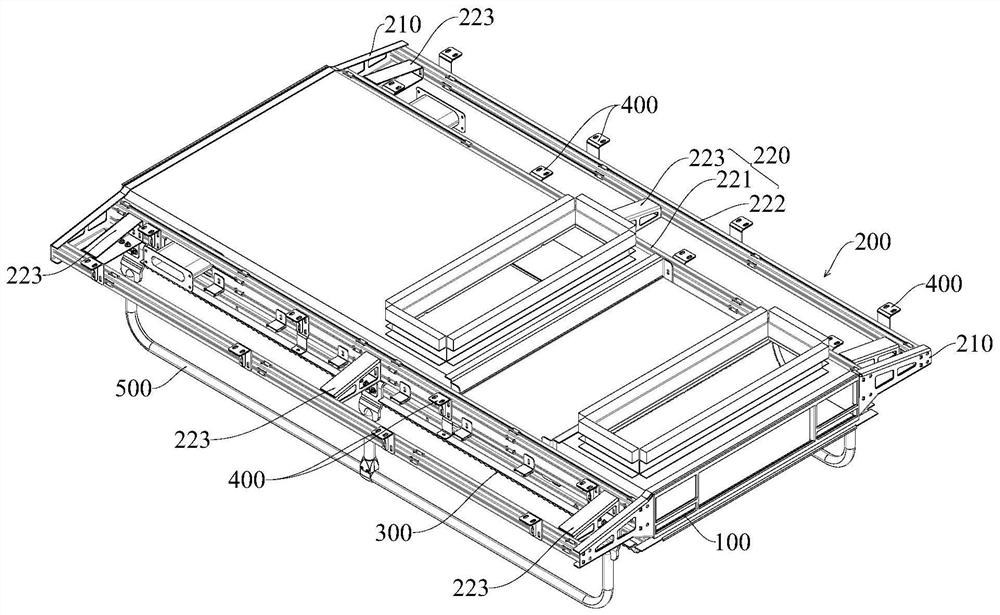

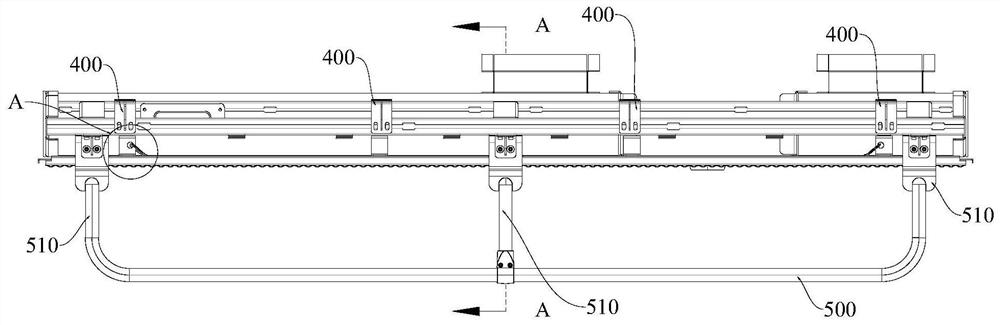

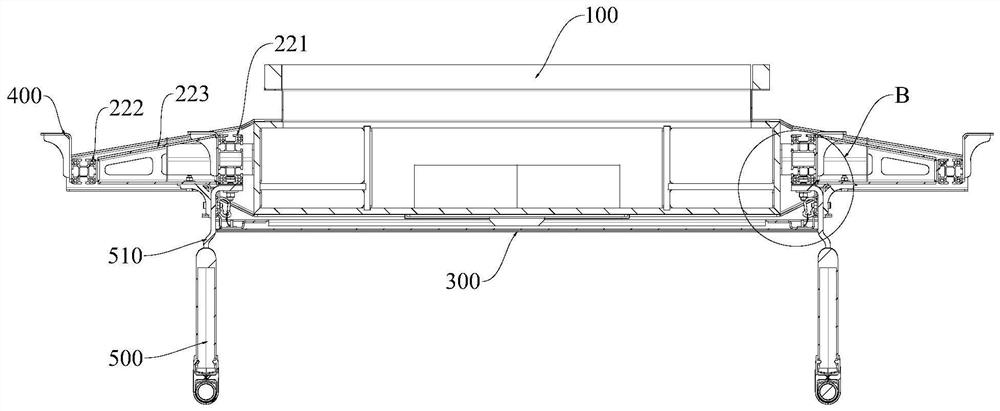

[0034] The hanger 400 is used to connect with the C-shaped groove on the roof. The limiting portion 600 is used to install the armrest 500 on the frame 200

[0036] The rail vehicle modular roof structure provided by the embodiment of the present invention, compared with the prior art, by eliminating the secondary

[0039] The socket portion 210 is socketed with the air-conditioning air duct 100 to ensure the stability of the connection relationship between the socket portion 210 and the air-conditioning air duct 100.

[0042] The frame 220 adopts the combination of two profiles and the first connector 223, so that the frame 220 has a simple structure.

[0043] The rail vehicle modular roof structure provided by this embodiment simplifies the frame 200 used for the installation of the middle roof 300

[0044] Further, each profile is connected with the corresponding socket part 210 through bolts or screws. The first profile 221 and the first

[0047] The handrail 500 is respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com