A swing structure and swing method of a steel pipe inner wall descaling machine

A technology for the inner wall of a steel pipe and a derusting machine, which is applied in the direction of abrasive jetting machine tools, used abrasive processing devices, metal processing equipment, etc., can solve problems such as low efficiency, inability to move, multiple hoisting, etc., and achieve the goal of improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0049] The following is a specific implementation of a steel pipe inner wall rust remover.

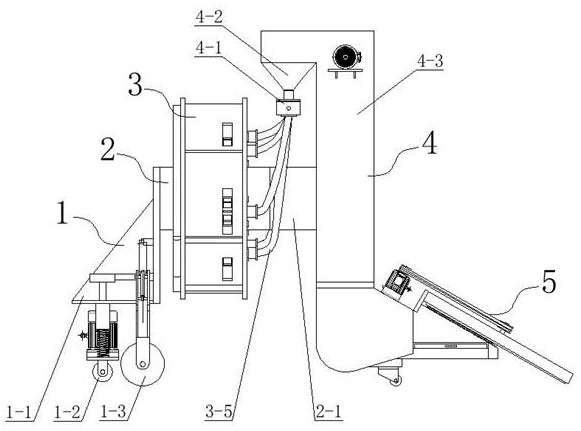

[0050] combine figure 1 As shown, a steel pipe inner wall rust removal machine in this embodiment includes: a traveling mechanism 1, a frame body 2, a rust removal mechanism 3, a lifting mechanism 4 and a separator 5, and the front end of the frame body 2 is provided with a traveling mechanism 1. The middle of the frame body 2 is provided with a rust removal mechanism 3, the rear end of the frame body 2 is provided with a lifting mechanism 4, the lower end of the lifting mechanism 4 is connected with a separator 5, and the upper end of the lifting mechanism 4 is connected with the rust removal mechanism 3; A traveling mechanism 1 is set on the rust remover to make the rust remover easy to move. When in use, the rust remover is moved to the position of the steel pipe for rust removal, which avoids the lifting of the steel pipe. When the rust remover is moved to the steel pipe After the...

specific Embodiment approach 2

[0059] The following is a specific implementation of the rust removal mechanism of a steel pipe inner wall rust remover.

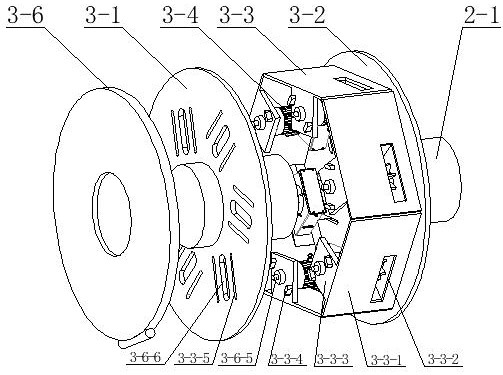

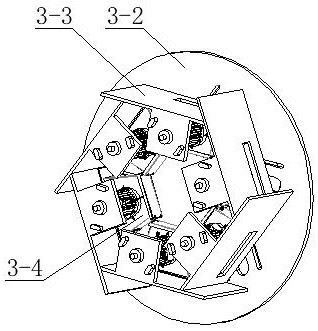

[0060] The rust removal mechanism of a steel pipe inner wall rust remover in this embodiment can be implemented independently or as a key technology in the first embodiment. combine figure 1 and figure 2 As shown, the derusting mechanism 3 includes: a front baffle 3-1, a rear baffle 3-2, a side plate 3-3, a shot blasting device 3-4 and a blasting device hose 3-5. The baffle 3-1 and the rear baffle 3-2 are circular plates arranged coaxially and in parallel, and several side plates 3-3 are arranged between the front baffle 3-1 and the rear baffle 3-2. The plates 3-3 are respectively arranged along the sides of a regular polygon, each side plate 3-3 is slidably arranged on the front baffle 3-1 and the rear baffle 3-2, and the sliding direction of each side plate 3-3 is All along the diagonal direction of the regular polygon, the inner side of each side pl...

specific Embodiment approach 3

[0062] The following is a specific implementation of the side plate of a steel pipe inner wall descaling machine.

[0063]The side plate of a steel pipe inner wall rust remover in this embodiment can be implemented independently or as a key technology in the first embodiment, and the second embodiment can also be further limited.

[0064] combine figure 2 As shown, the side plate 3-3 includes: a side plate body 3-3-1, a shot blasting port 3-3-2, a side connecting plate 3-3-3, a connecting plate slider 3-3-4 and a connecting plate The plate slider groove 3-3-5, the inner side of the side plate body 3-3-1 is fixedly connected with a shot blasting device 3-4, and the side plate body 3-3-1 is connected to the opening of the shot blasting device 3-4 A shot blasting port 3-3-2 is correspondingly arranged, and a side connecting plate 3-3-3 is arranged on the side of the side plate body 3-3-1 close to the front baffle 3-1. The connecting plate slider 3-3-4 is provided, and the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com