Material storage box mechanism and material storage device

A material storage box and material box technology, applied in the direction of unloading device, transportation and packaging, packaging, etc., can solve the problems of low material storage capacity, single structure and function of the storage box, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The material storage box mechanism provided in this embodiment is used for storing sheet materials or plate materials, such as product brochures and the like.

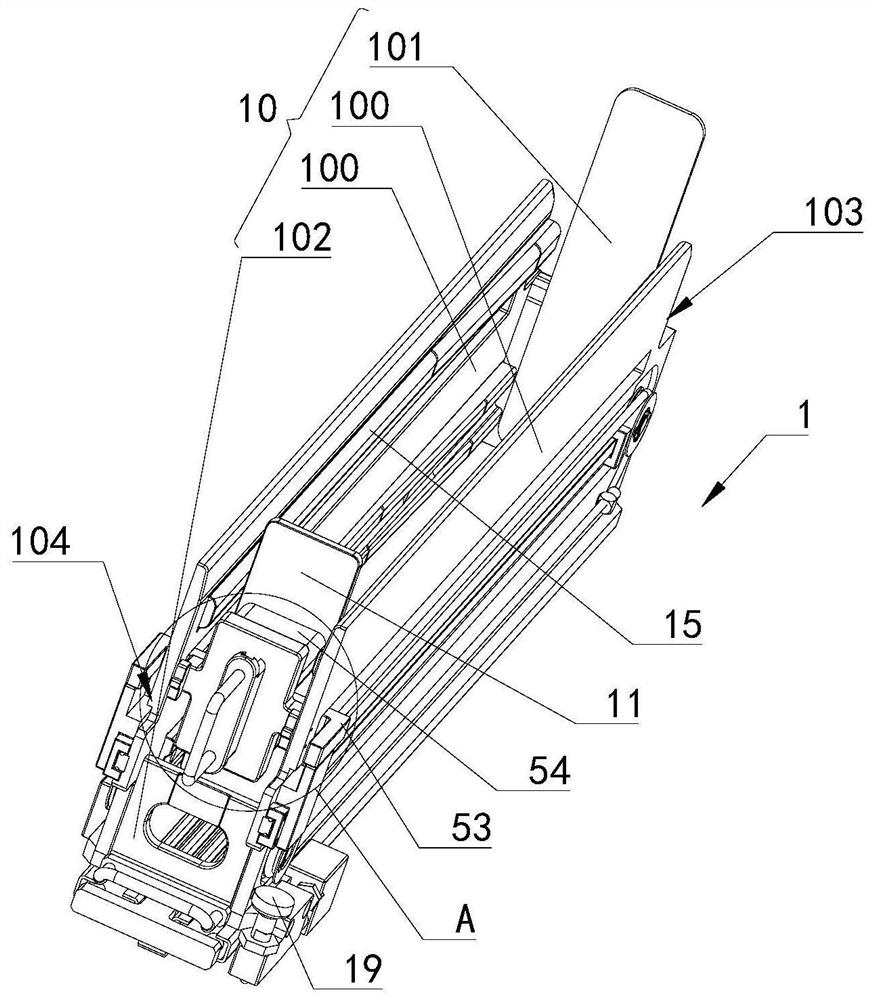

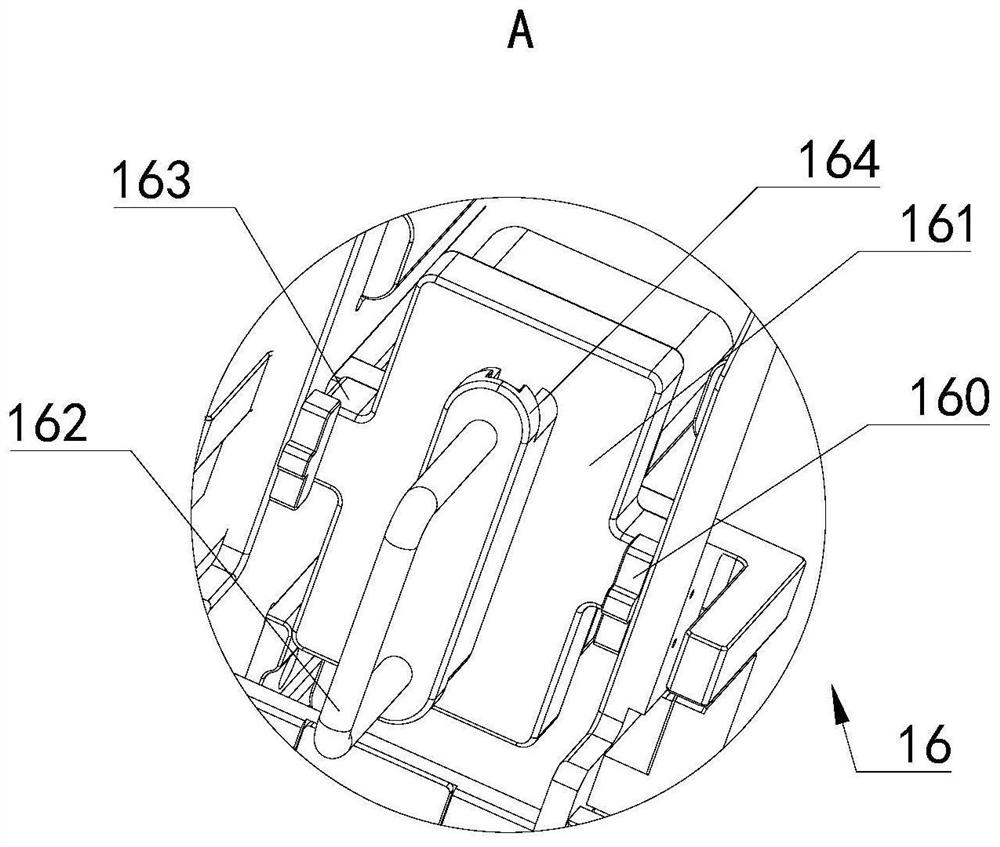

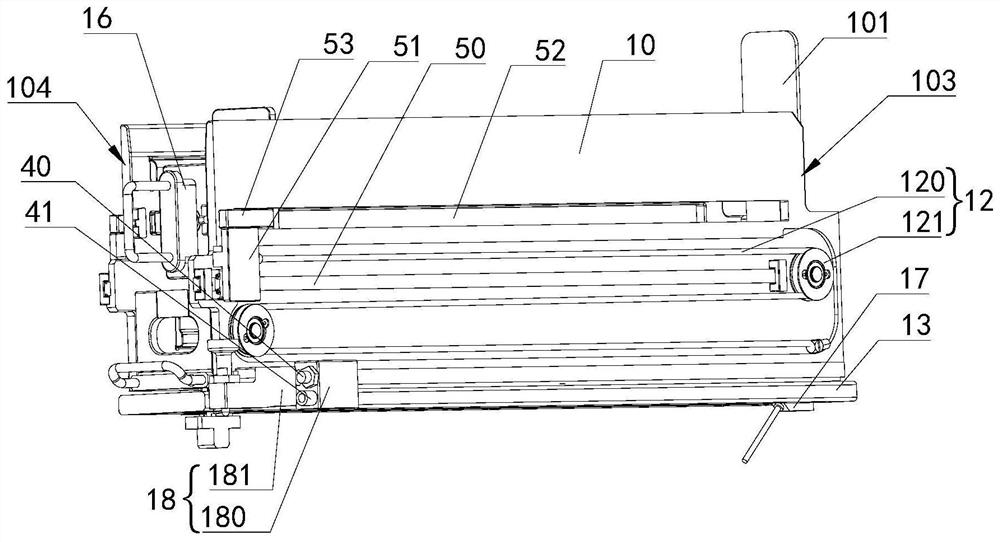

[0048] see Figure 1 to Figure 4 and combine Figure 5 and Figure 6 As shown, the storage box mechanism 1 provided in this embodiment includes a base, a box body 10 , a pressure plate 11 , a pressure plate locking component 16 , a box body 10 locking component and an elastic reset component 12 .

[0049] Hereinafter, the above-mentioned components of the storage box mechanism 1 will be described in detail:

[0050] In an optional solution of this embodiment, a storage space for materials to be stacked sequentially along the first direction is formed in the box body 10, and the two ends of the box body 10 along the first direction are defined as the first end 103 and the second end respectively. 104 , materials can be stacked sequentially between the first end 103 and the second end 104 , the pressing plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com