Efficient dust collection device for weft knitting machine

A technology of dust collection device and weft knitting machine, which is applied in knitting, textiles and papermaking, etc., and can solve problems such as low dust removal efficiency, company loss, flying flowers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

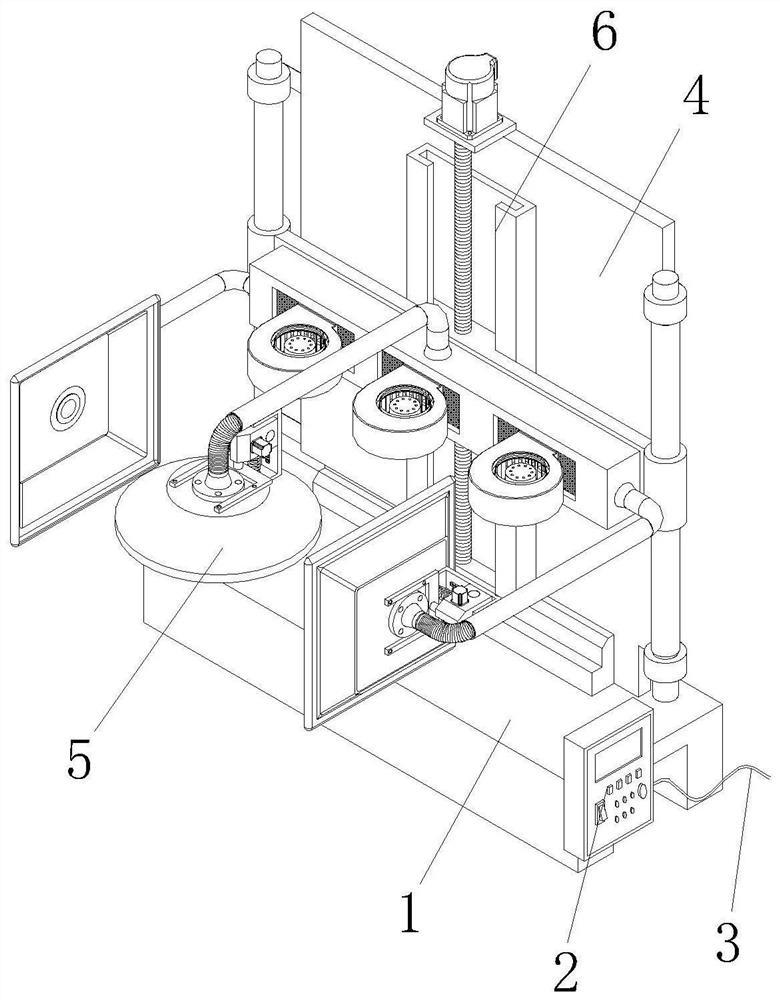

[0031] see figure 1 As shown, the present invention provides a high-efficiency dust collection device for knitting and weft knitting machines through improvement, including a support base 1, a control panel 2, a power cord 3 and a support vertical plate 4, and a control panel is provided on the right side of the support base 1. Panel 2, the set control panel 2 is used to control the opening and closing of the motor of the device. The control panel 2 is connected with a power cord 3, which can be connected to an external power supply to provide power for the device. The plate 4 is used to support the dust collection equipment, the multi-directional dust suction device 5 and the overall adjustment mechanism 6 , the front end of the support vertical plate 4 is equipped with the overall adjustment mechanism 6 , and the multi-directional dust suction device 5 is installed on the overall adjustment mechanism 6 .

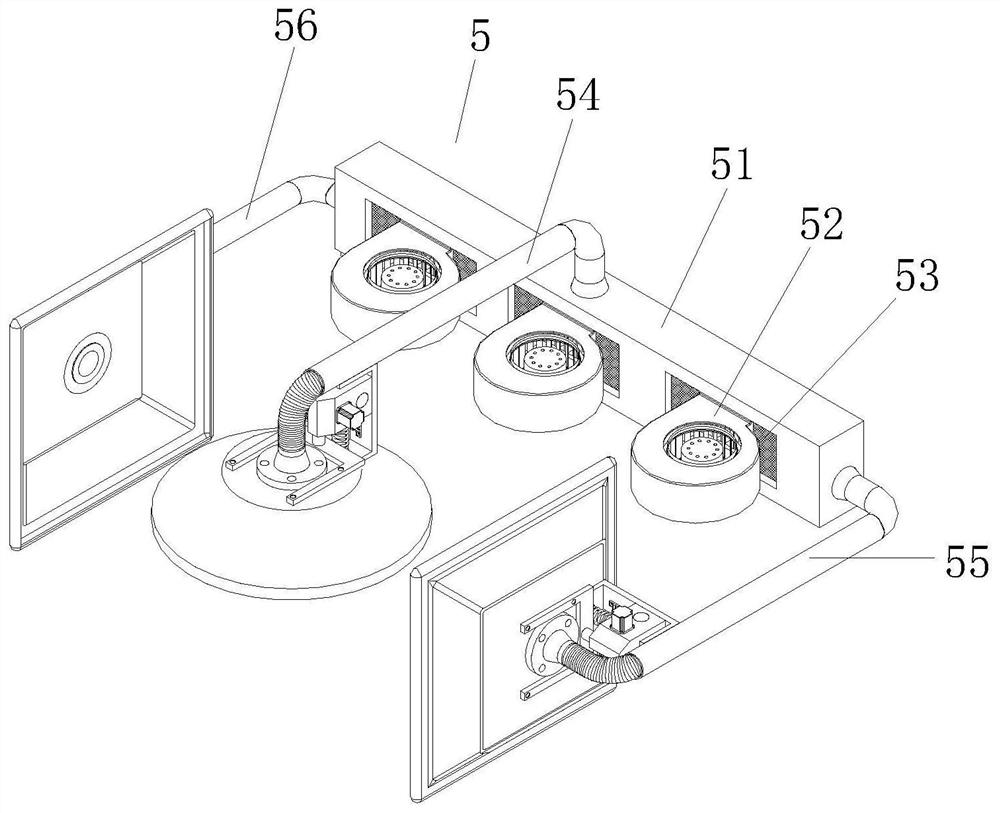

[0032] see figure 2As shown, the present invention provides a kind ...

Embodiment 2

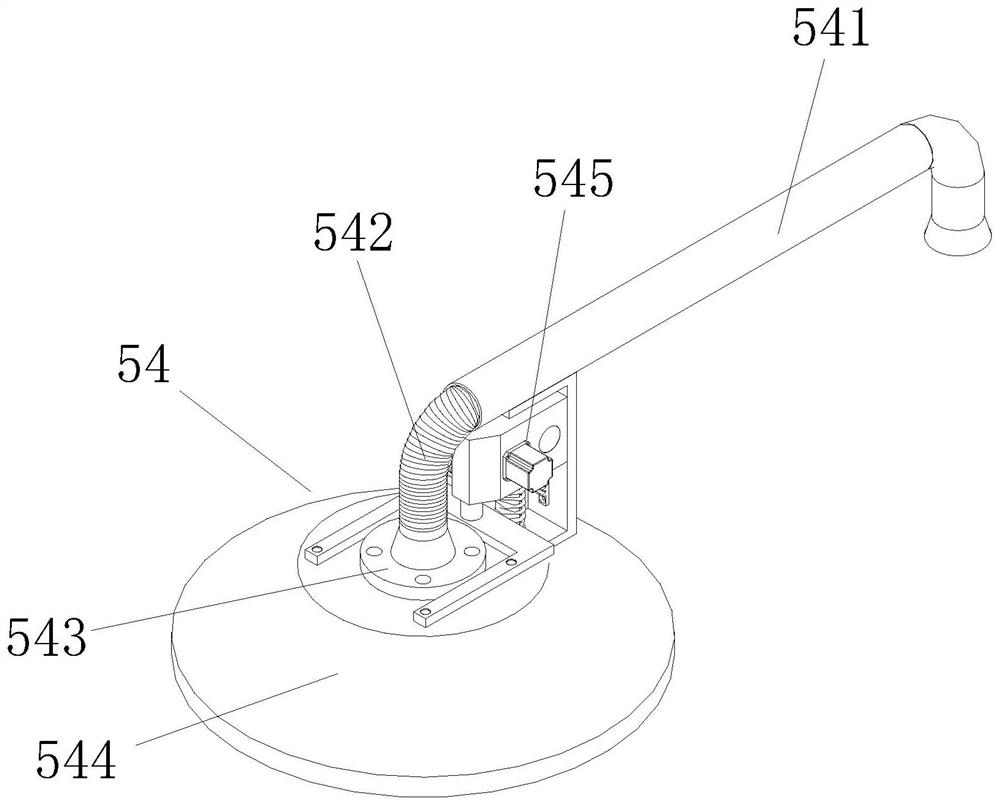

[0038] The present invention provides a high-efficiency dust collection device for knitting and weft knitting machines through improvement. The bottom of the collection box 51 is provided with an openable cleaning door, which is convenient for cleaning the lint and dust collected in the collection box 51. To maintain the follow-up dust collection work, the circular structure of the circular dust suction disc 544 is arranged to facilitate better dust collection on the upper end of the knitting weft knitting machine, while the rectangular dust suction disc 554 is set to a rectangular structure, which is convenient for the weft knitting machine. Dust is sucked sideways, the first connecting telescopic tube 542 and the second connecting telescopic tube 552 can be telescopically adjusted, so that the adjustment of the circular dust suction cup 544 and the rectangular dust suction cup 554 is not affected, and the first connection telescopic The ends of the pipe 542 and the second con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com