Effective spraying device for wet tissue liquid during wet tissue production

A technology of spraying device and wet wipes, which is applied in the direction of processing textile material carriers, spraying/spraying textile materials, etc., which can solve the problems of troublesome and laborious manual unloading and the inability to fix the loading frame.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

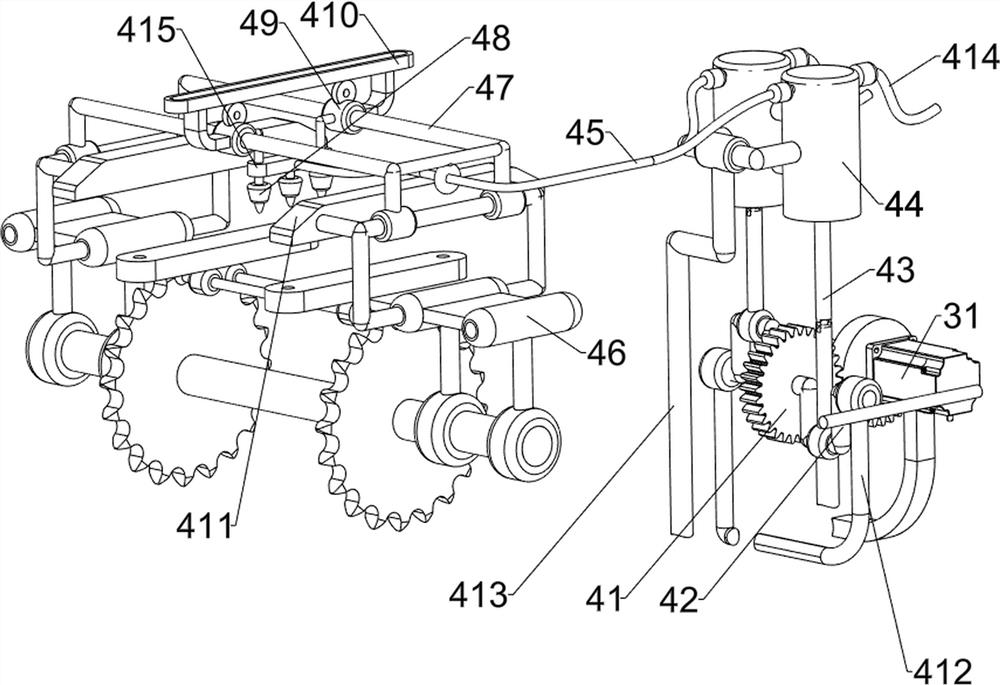

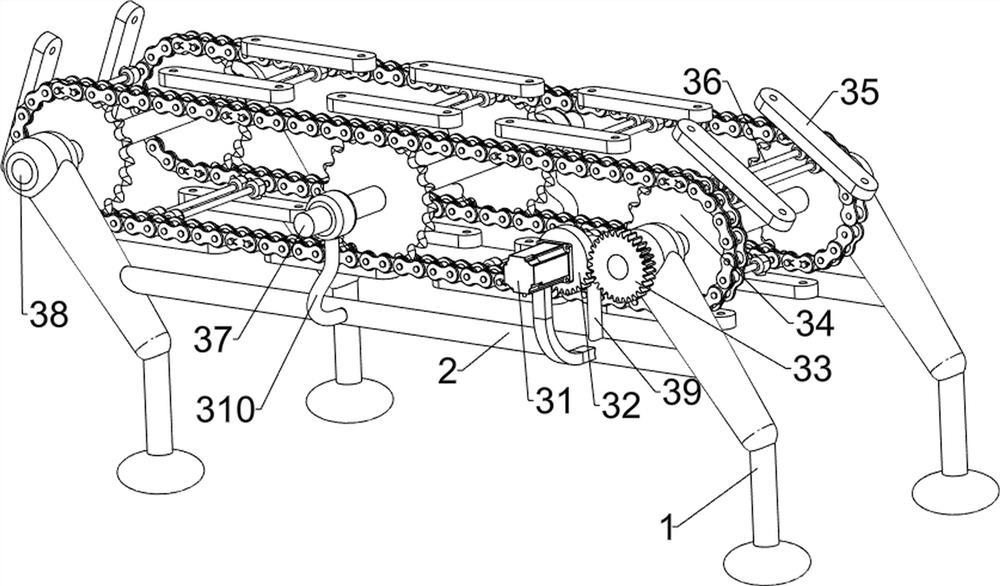

[0030]An effective spraying device for wet wipe liquid during wet wipe production, such as figure 1 , figure 2 and image 3 As shown, it includes a support foot 1, a crossbeam 2, a transmission mechanism 3 and a spray mechanism 4. The support feet 1 are symmetrically arranged on the front and rear sides of the ground, and the middle part of the support feet 1 on the front and rear sides is connected with a crossbeam 2. A transmission mechanism 3 is provided between the upper part of the support foot 1 and the crossbeam 2 , and a spray mechanism 4 is provided between the right part of the front crossbeam 2 and the transmission mechanism 3 .

[0031] The transmission mechanism 3 includes a motor 31, a half gear 32, a first gear 33, a chain sprocket assembly 34, a placement block 35, a connecting shaft 36, a fixed shaft 37, a rotating shaft 38, a first support base 39 and a second support base 310, A motor 31 is installed on the right front side upper part of the front crossbe...

Embodiment 2

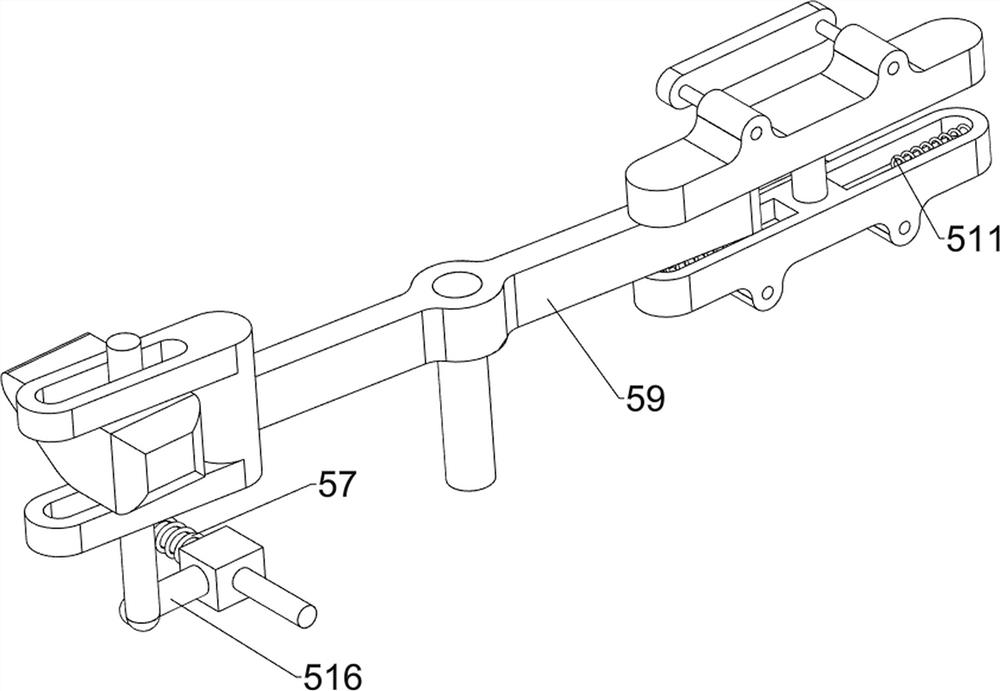

[0035] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, the clamping assembly 5 is also included, and the clamping assembly 5 includes a right-angle rod 51, a first spring 52, a connecting plate 53, a second wedge 54, a third wedge 55, a fourth wedge 56, a second wedge Spring 57, connection seat 58, swing bar 59, press seat 510, the third spring 511, wedge-shaped pressing block 512, the fourth spring 513, the third support frame 514, support rod 515 and slide bar 516, place block 35 left and right sides The right-angled rods 51 are all slidably connected, and the right-angled rods 51 cooperate with the first wedge-shaped block 411. The connecting plates 53 are connected between the insides of the right-angled rods 51, and there are first left-right symmetrical connections between the connecting plates 53 and the placement block 35. Spring 52, the first spring 52 is enclosed within on the right-angle bar 51...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com