Fuel pumping control method and system and vehicle

A control method and a fuel pump technology, applied in the field of vehicles, can solve the problems of reduced methanol pressure, insufficient engine combustion, affecting fuel injection quantity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

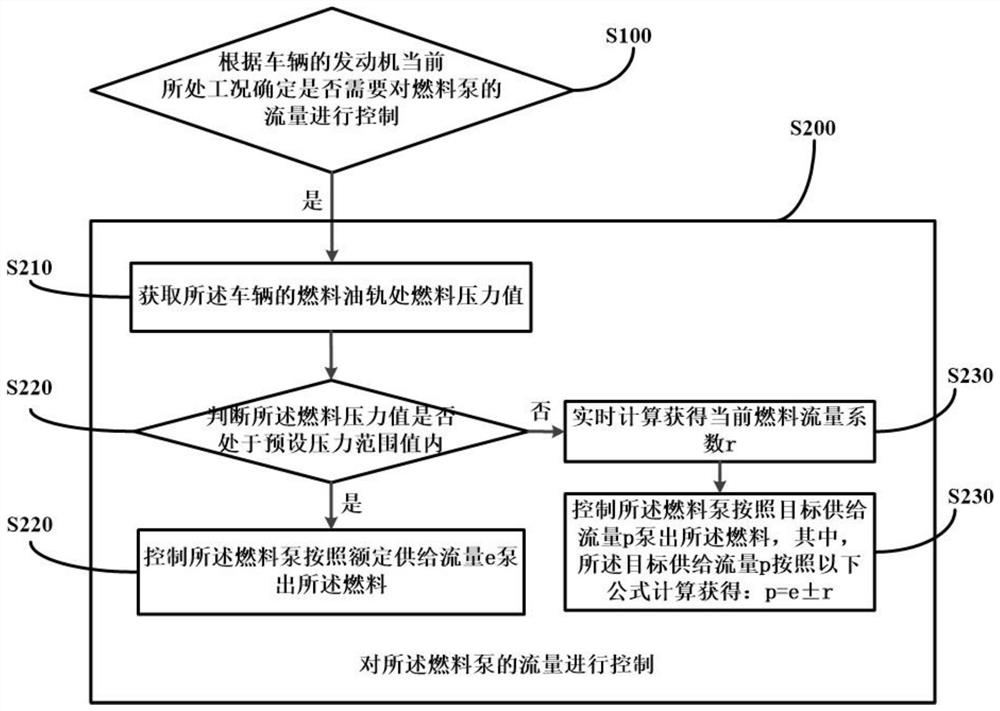

[0034] figure 1 A schematic flowchart of a fuel pumping control method according to an embodiment of the present invention is shown.

[0035] Such as figure 1 As shown, the fuel pumping control method includes:

[0036] Step S100, determining whether to control the flow rate of the fuel pump according to the current working condition of the engine of the vehicle;

[0037] Step S200, when the need is determined, the flow rate of the fuel pump is controlled as follows:

[0038] Step S210, obtaining the fuel pressure value at the fuel rail of the vehicle;

[0039] Step S220, judging whether the fuel pressure is within a preset pressure range, and when it is determined that the fuel pressure is within a preset pressure range, controlling the fuel pump to pump out the fuel according to the rated supply flow rate e;

[0040] Step S230, when it is determined that the fuel pressure value is not within the preset pressure value range, calculate and obtain the current fuel flow coef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com