A reflector and difference network antenna

A reflective surface and parabolic antenna technology, applied in the direction of antennas, waveguide horns, electrical components, etc., can solve the problems of beam deformation, influence and poor beam performance, side lobe improvement, etc., achieve simple shape and structure, reduce occlusion effect, improve Effects on Radar Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

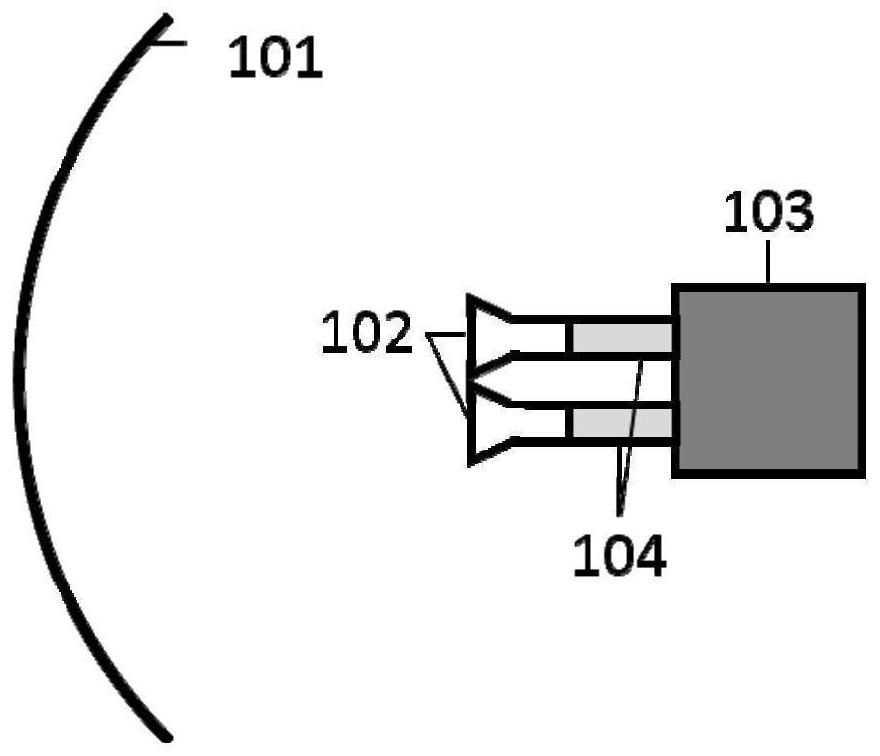

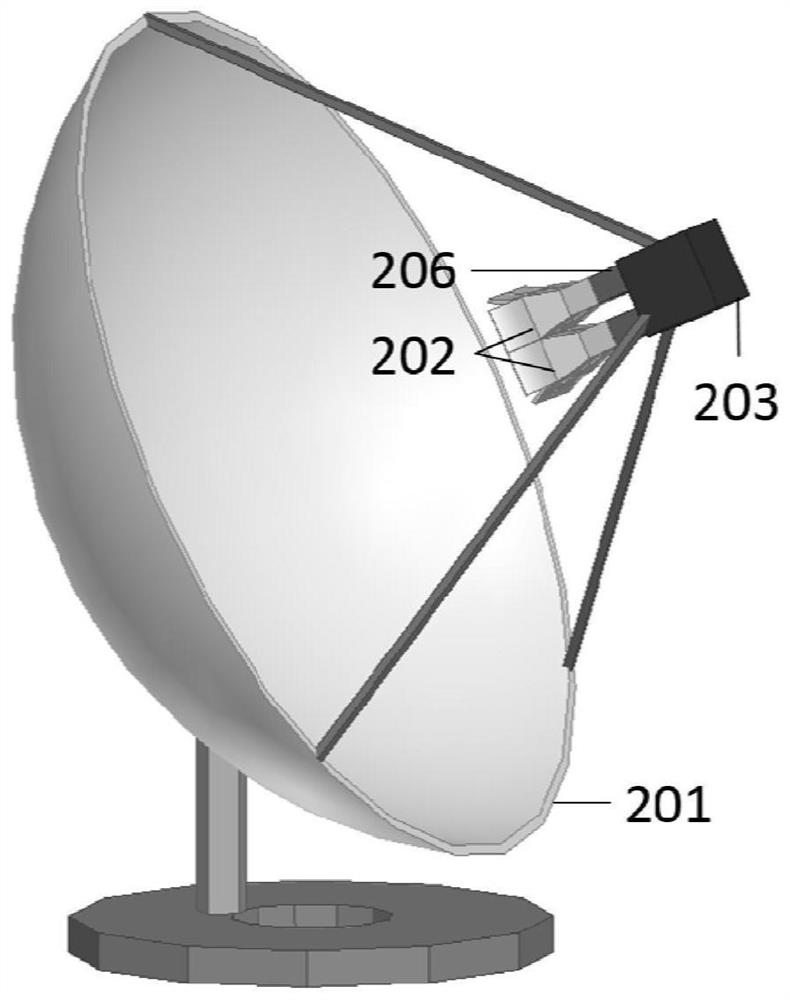

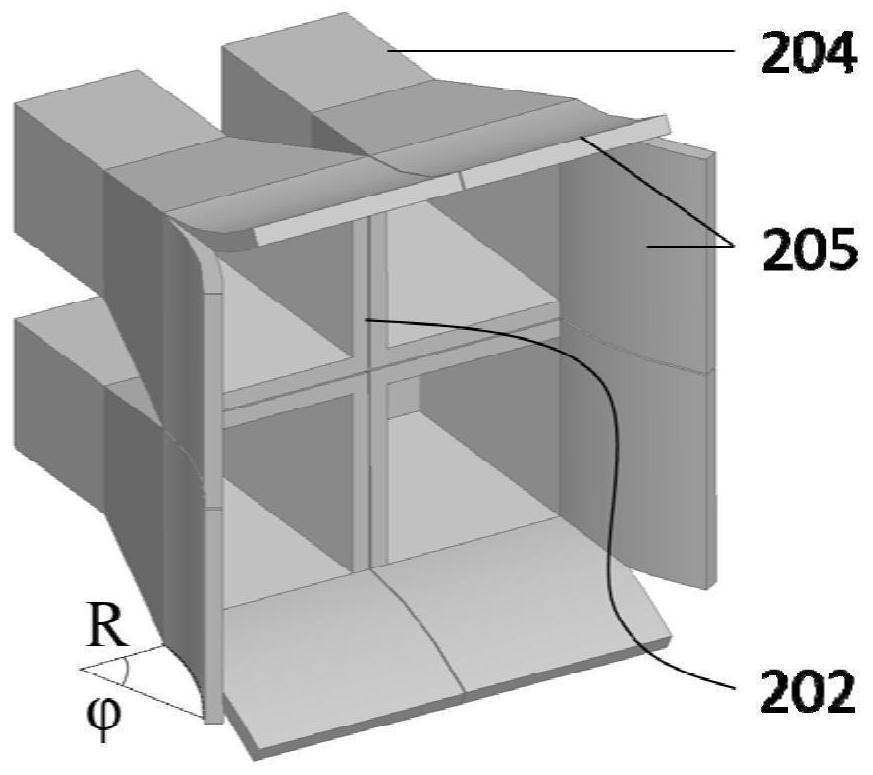

[0027] refer to figure 2 , image 3 , this example is designed as a reflector antenna with a 2×2 array feed, and the design steps are as follows: The 2×2 array reflector antenna in this example includes a reflector antenna 201, a pair of monaural horn feeds 202, and a sum-difference Network 203. In the antenna, the reflector antenna 201, the sum-difference network 203, and the standard waveguide are common structures. The monaural horn feed 202 is extended from a standard waveguide structure 204 to a horn antenna, and the monaural structures 205 are extended on both sides thereof. It should be noted that in this example, because the feed array is a 2×2 structure, each feed horn is a monoaural horn feed, and all monoaural structures are a section of cylindrical surface with a radius of R , the angle is All single-ear structures together wrap the outermost side of the entire array. If the feed array has more than 2 rows or 2 columns of speaker feeds, it is only necessary ...

Embodiment 2

[0029] The beam shape designed in this example is a fan beam, the working frequency range is 76-77 GHz, the working mode is horizontal scanning, and the structure is a box reflector antenna.

[0030] The present invention belongs to a feed-forward parabolic reflector antenna, and the design steps are as follows: Figure 4 As shown, the sector and difference beam horizontal scanning box antenna is composed of a reflector antenna 301, a pair of metal plates 302, a pair of transition structures 304, a pair of monaural horn feeds 303, a curved waveguide 305, and a sum-difference network 306. . First, determine the size of the parabolic reflector. According to the central operating frequency of 76.5GHz, the corresponding operating wavelength λ is calculated to be about 3.92mm, and then the diameter of the rectangular aperture field of the parabolic reflector D (D E and D H ) are estimated from the target azimuth and elevation angles of the sum beam respectively, and the empirica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com