A kind of raw material cutting equipment for new energy vehicle circuit board

A new energy vehicle and cutting equipment technology, applied in the field of new energy vehicle circuit board raw material cutting equipment, can solve the problems of high use limitation and poor cutting effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

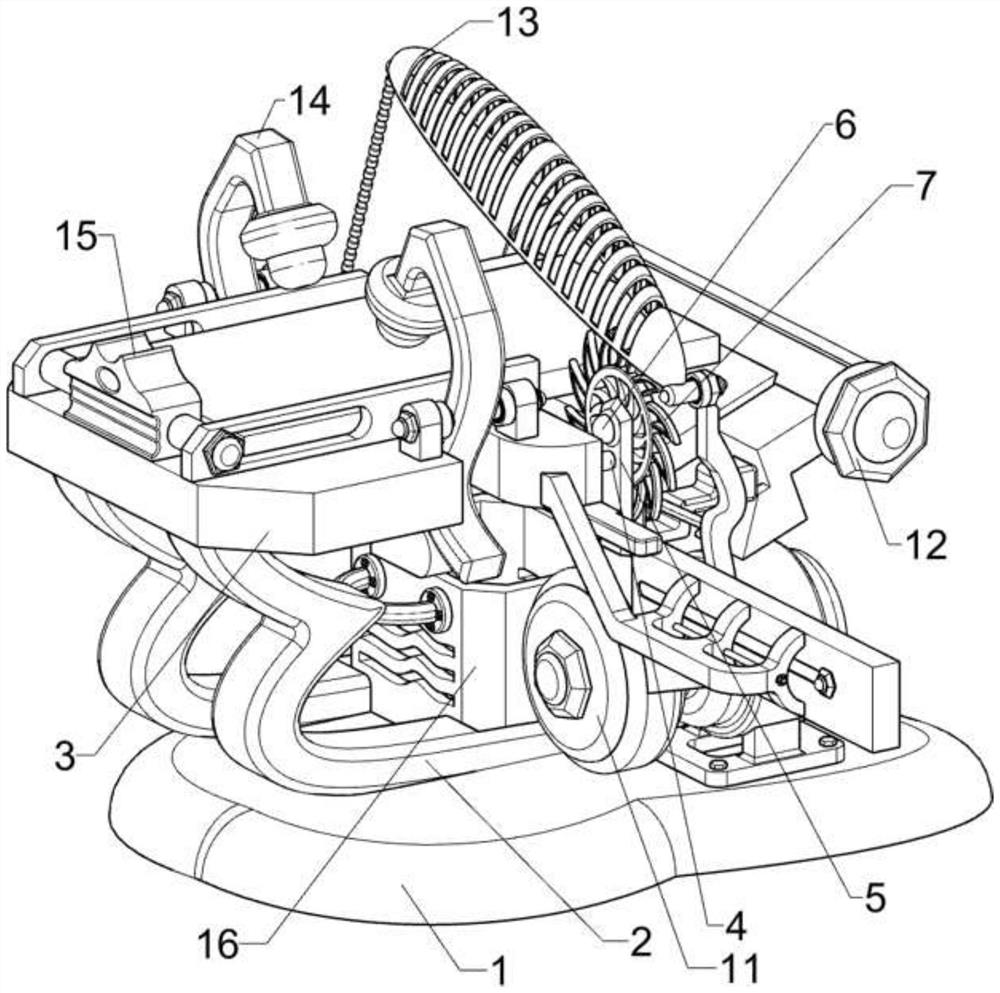

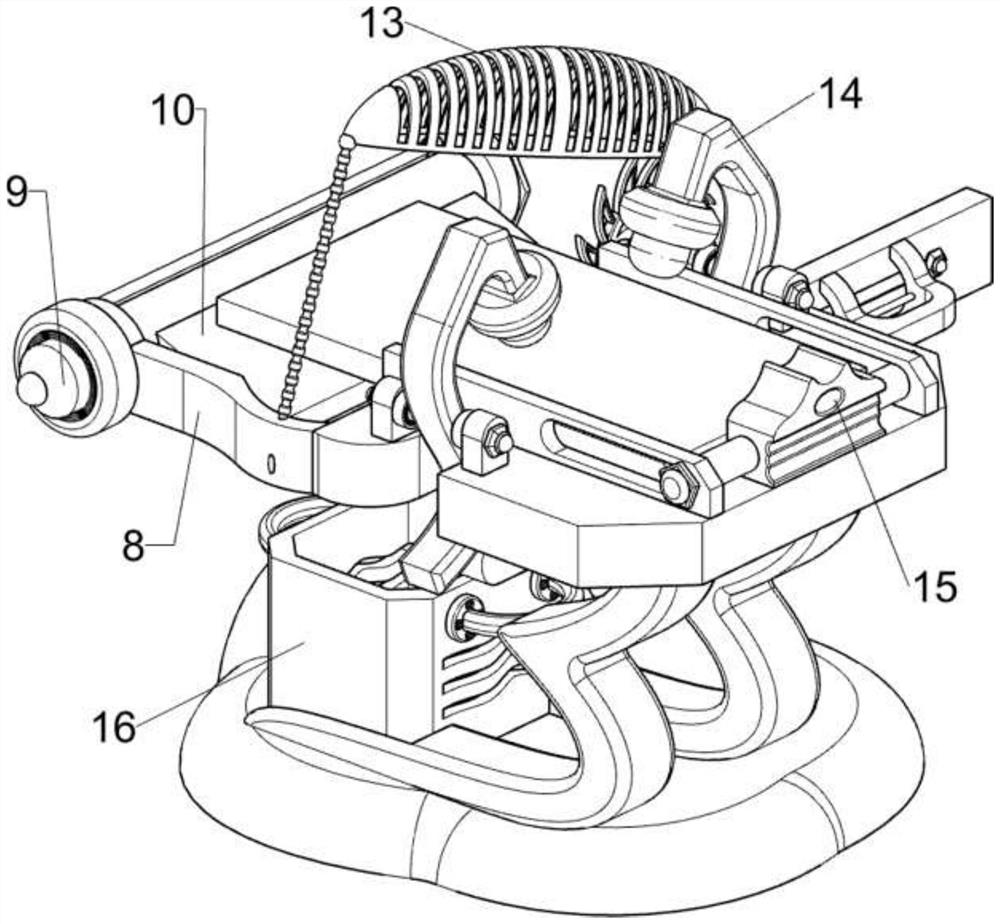

[0028] A raw material cutting equipment for circuit boards of new energy vehicles, such as Figure 1-5 As shown, it includes a bottom plate 1, a bracket 2, a first mounting plate 3, a first guide rod 4, a first connecting plate 5, a brushless motor 6, a cutter 7, a first connecting frame 8, a first rotating shaft 9, a first Two mounting plates 10, a power mechanism 11 and a residual material removal mechanism 12, two brackets 2 are arranged on the rear side of the bottom plate 1, a first mounting plate 3 is arranged between the tops of the brackets 2, and the right side of the first mounting plate 3 is slidably connected with a The first guide rod 4, the right side of the first guide rod 4 is provided with a first connecting plate 5, the first connecting plate 5 is provided with a brushless motor 6, the output shaft of the brushless motor 6 is connected with a cutter 7, and the first mounting plate 3. The right part of the rear side is provided with a first connecting frame 8,...

Embodiment 2

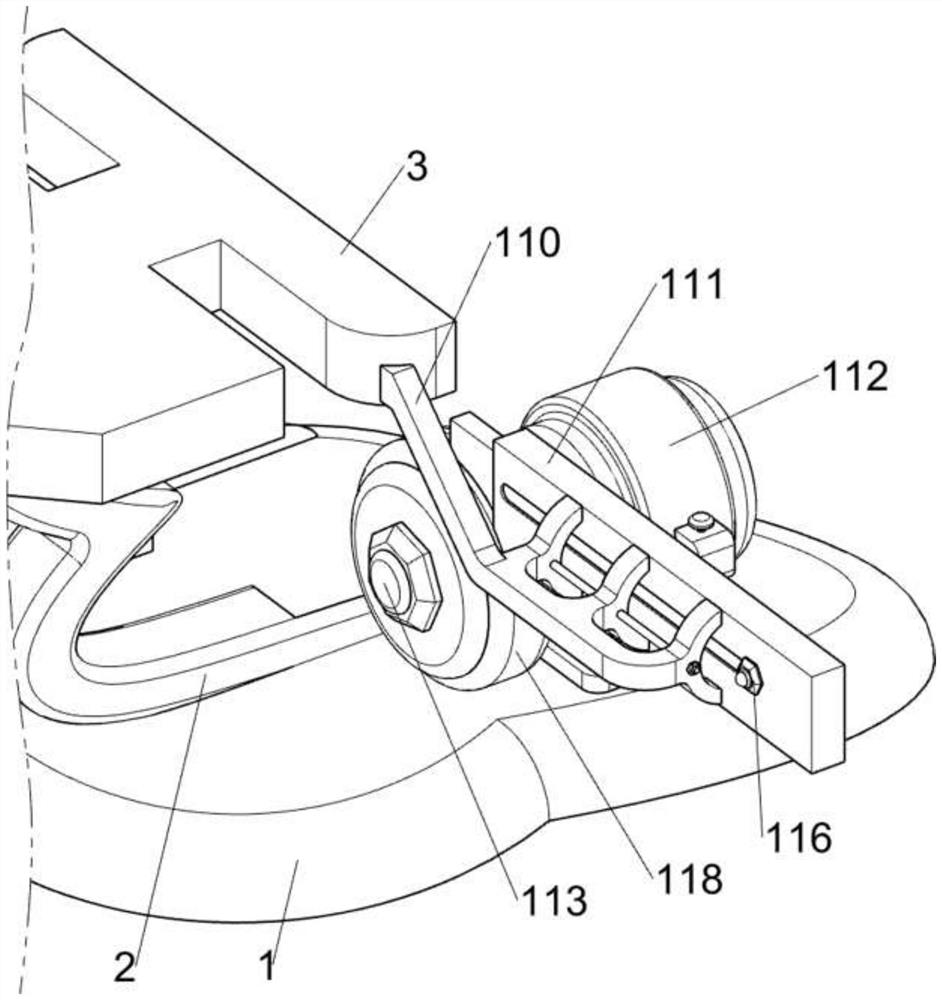

[0033] On the basis of Example 1, as Figure 6-10 As shown, a protection mechanism 13 is also included, and the protection mechanism 13 includes a first bearing seat 130, a second bearing seat 131, a reel 132, a traction wire 133, a third rotating shaft 134, a second scroll spring 135 and a protective cover 136. A first bearing seat 130 is provided on the right rear side of the guide rail 111, a second bearing seat 131 is provided on the lower side of the rear part of the first bearing seat 130, and a reel 132 is rotatably connected to the second bearing seat 131. The second bearing seat The upper part of 131 is rotatably connected with a third rotating shaft 134, a second scroll spring 135 is connected between the third rotating shaft 134 and the second bearing seat 131, and a pulling wire 133 is arranged on the lower right side of the first connecting plate 5, and the pulling wire 133 is wound around Passing through the reel 132 , the pulling wire 133 passes through the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com