Electrical cabinet

A technology of electrical cabinets and outer boxes, applied in the field of electrical cabinets, can solve the problems of waste of resources, occupying space in electrical cabinets, and many fans, and achieve the effect of improving the effect of dust removal and space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the purpose, technical solution and advantages of the present disclosure clearer, the implementation manners of the present disclosure will be further described in detail below in conjunction with the accompanying drawings.

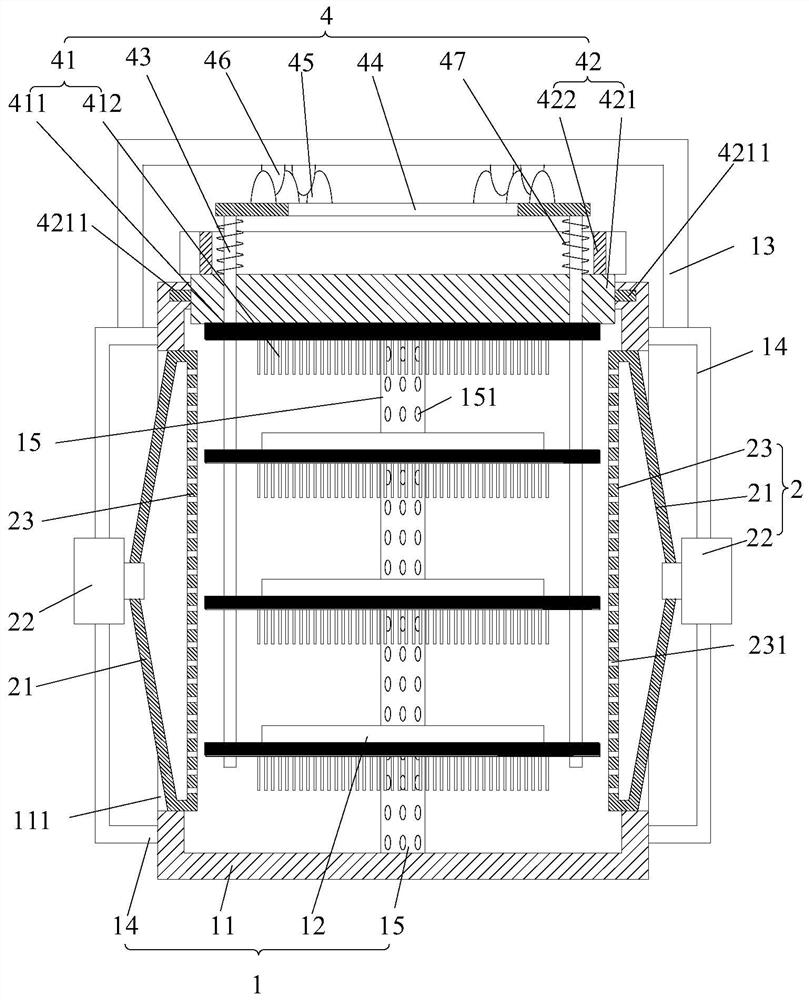

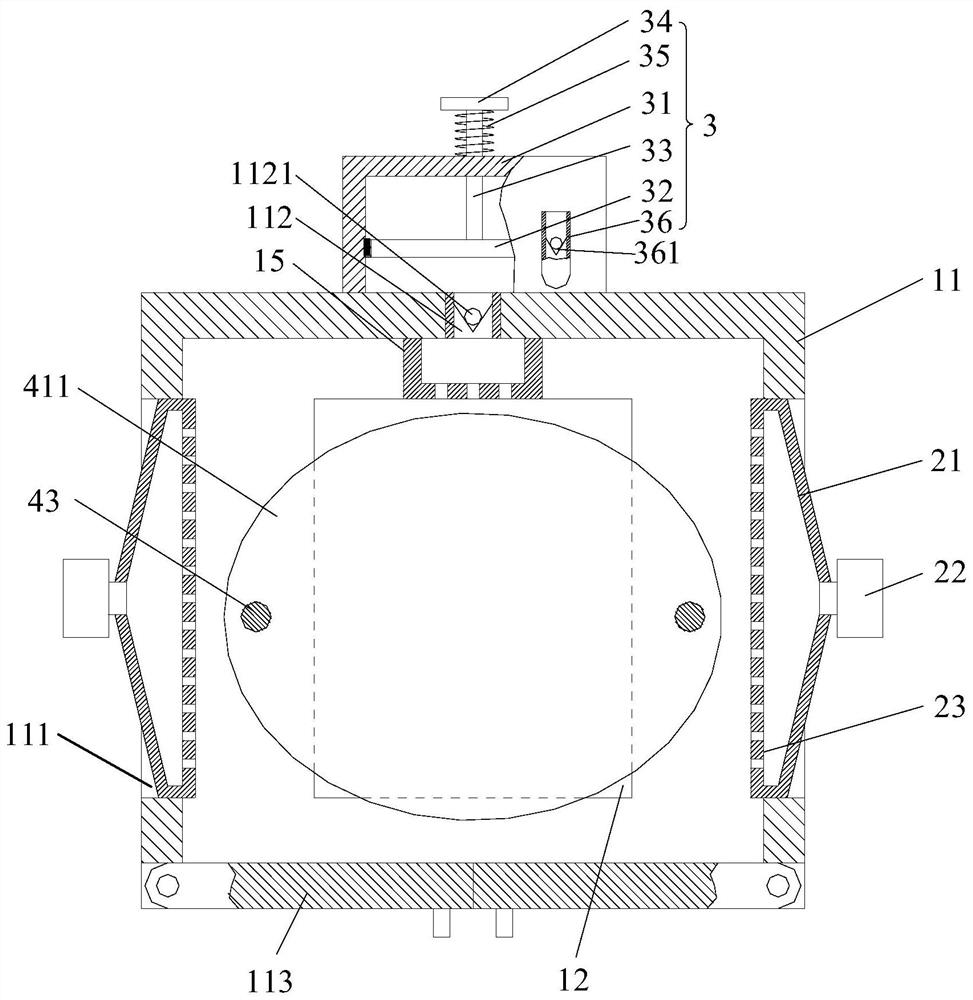

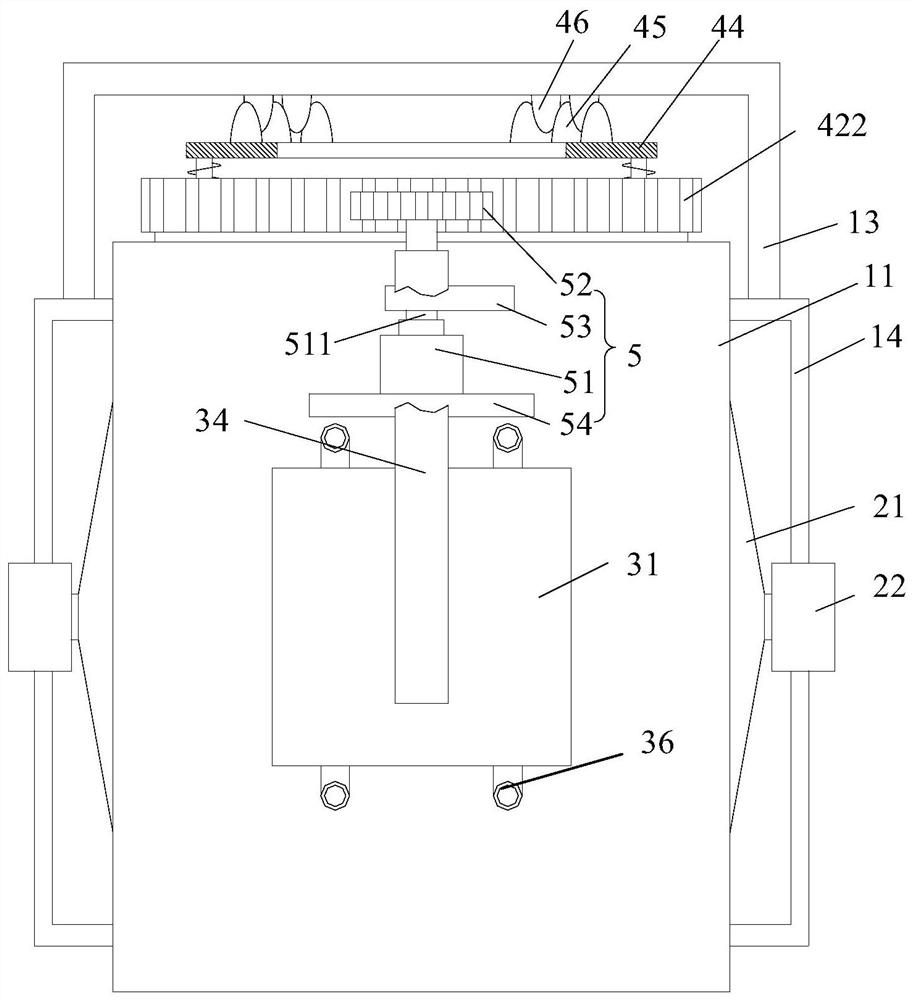

[0054] An embodiment of the present disclosure provides an electrical cabinet, such as figure 1 As shown, the electrical cabinet includes a box body 1 , a blower assembly 2 , an air pump 3 , a cleaning assembly 4 and a drive assembly 5 . The box body 1 includes an outer box 11 and a plurality of mounting plates 12. The side wall of the outer box 11 has an air inlet 111 and an air outlet 112. The air inlet 111 and the air outlet 112 are respectively located on different side walls of the outer box 11. Multiple mounting plates 12 is connected to the inner side wall of the outer box 11, and a plurality of mounting plates 12 are arranged at intervals along the vertical direction. The blowing assembly 2 is located in the air inlet 111 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com