Method for reducing content of higher alcohols in yellow wine

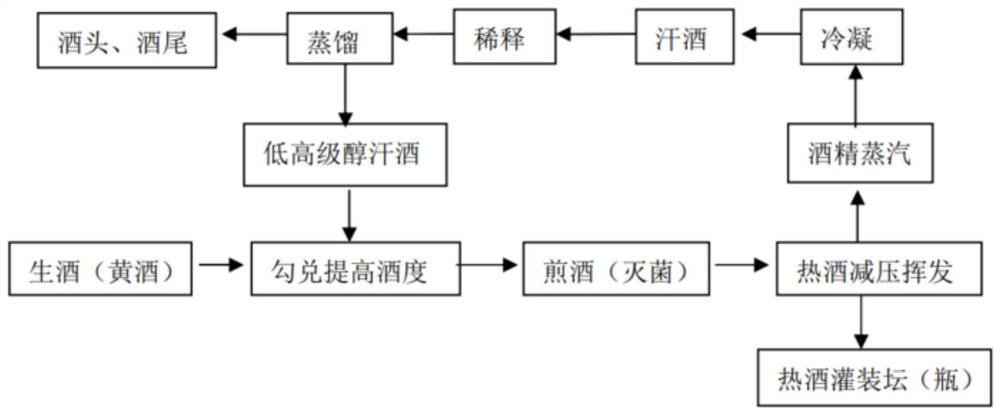

A technology with middle and high alcohol content, applied in the field of winemaking, can solve the problems of affecting fermentation performance, reducing rice wine, low alcohol content, etc., and achieve the effect of simple treatment method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Sweat wine redistillation: Dilute the sweat wine with an alcohol content of about 65% vol to 45% vol, add it to the still pot for re-distillation, use indirect steam heating for distillation, and cut off the head of 100kg of 45% vol sweat wine After 20kg, extract the 50kg redistilled sweat wine in the middle section for subsequent use.

[0028] (2) Blending: blending yellow rice wine raw wine with the redistilled perspiration wine with low and higher alcohol obtained in step (1), the alcohol content of the raw wine before blending is 18.5% vol, and the alcohol content of the raw wine after blending is 21.1% vol; Semi-finished rice wine without decoction obtained after the rice wine mash fermentation is completed and the distiller's grains are removed by pressing.

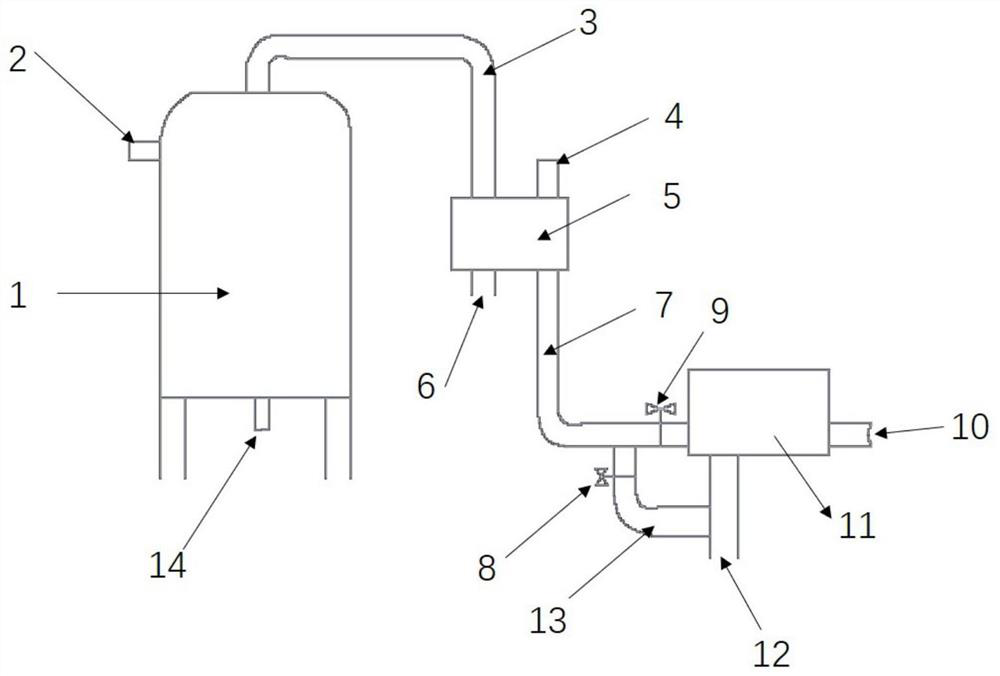

[0029] (3) Fried wine: heat the blended raw wine to 90-92°C and put it into a buffer tank.

[0030] (4) Decompression and volatilization: when the hot wine enters the buffer tank, open the first valve an...

Embodiment 2

[0039] (1) Sweat wine redistillation: Dilute the sweat wine with an alcohol content of about 65% vol to 45% vol with water, add it to the still pot for re-distillation, use indirect steam heating for distillation, and cut off the head of 20kg of 100kg of 45% vol sweat wine Finally, extract the middle section 50kg redistilled sweat wine for subsequent use.

[0040] (2) Blending: blending raw wine with the low-grade alcohol redistilled sweat wine obtained in step (1), the alcohol content of the raw wine before blending is 18.3% vol, and the alcohol content of the raw wine after blending is 21.2% vol; the raw wine refers to rice wine mash Semi-finished rice wine without decoction obtained by pressing to remove distiller's grains after fermentation.

[0041] (3) Fried wine: heat the blended raw wine to 90-92°C and put it into a buffer tank.

[0042] (4) Decompression and volatilization: when the hot wine enters the buffer tank, open the first valve and close the second valve. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com