Testing device for simulating flow erosion corrosion of pipeline

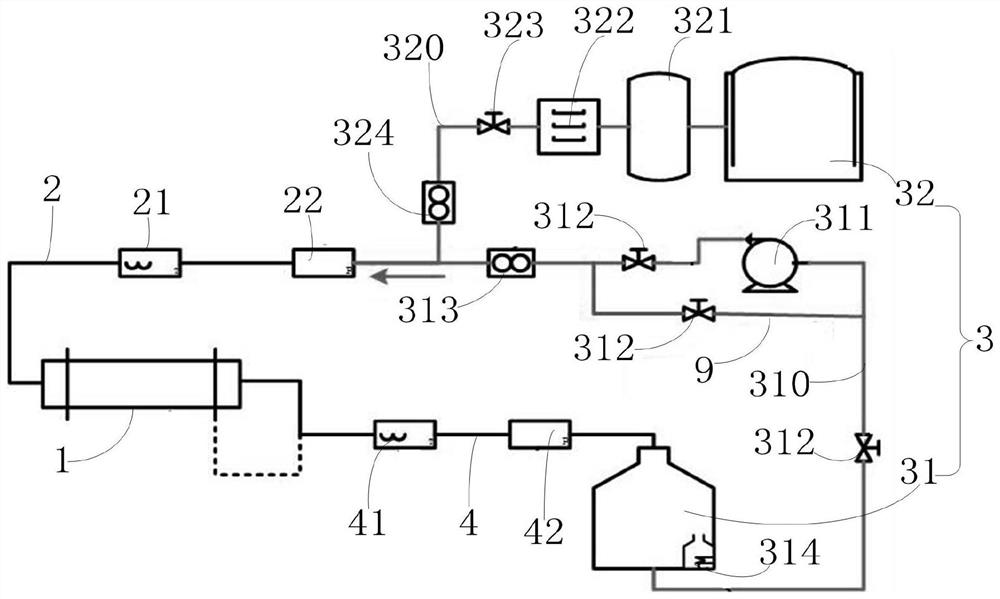

A test device and scouring corrosion technology, which is used in measuring devices, testing wear resistance, instruments, etc., can solve problems such as difficulty in avoiding losses, inability to arbitrarily adjust the inclination of test pipe fittings, and inability to simulate the effect of erosion and corrosion, and eliminate the flow field. perturbation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

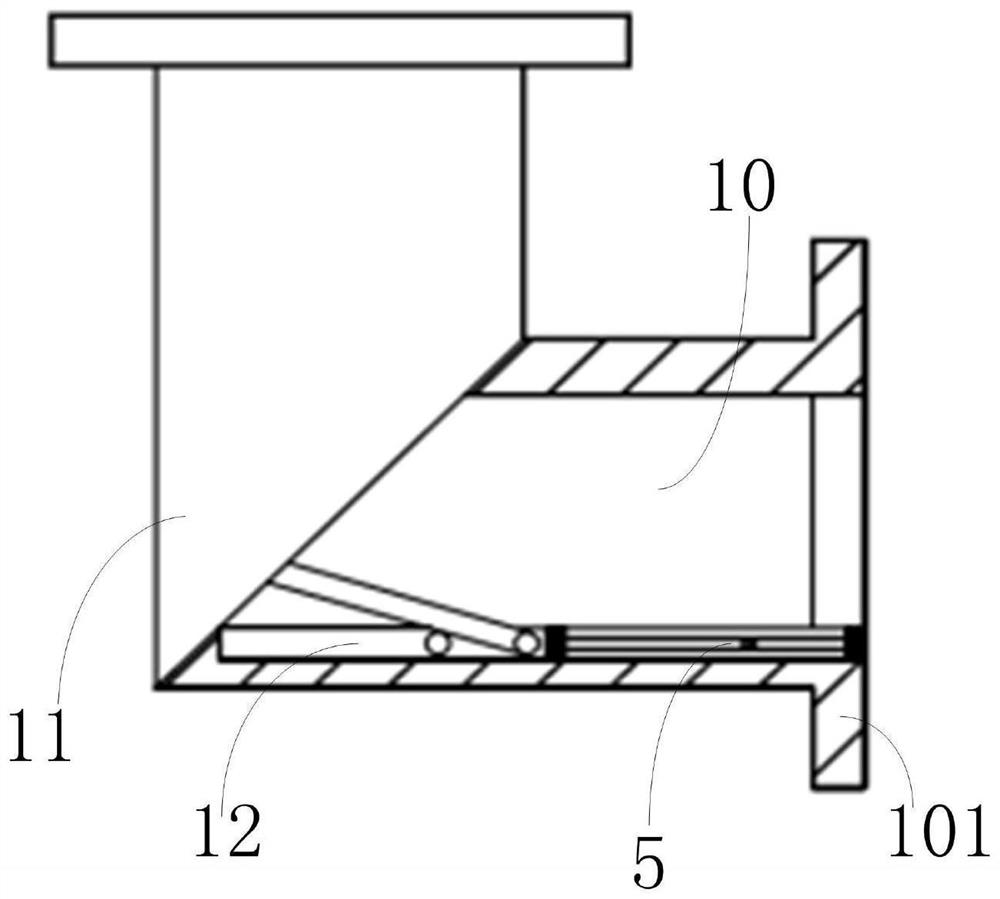

[0114] The invention provides a test device for simulating pipeline flow erosion and corrosion. The working principle of the simulation test for changing the angle of the test pipe fitting sample is as follows:

[0115] Cut a small piece from the pipeline for transporting fluid medium in actual working conditions as a test pipe sample, fix the test pipe sample on the test piece fixing plate 123 of the test piece fixing fixture 12, and then clamp the bottom plate 121 of the test piece fixing fixture 12 Connect it to the draw-in groove 110 provided on the inner wall of the test pipeline section 11 (the test pipeline section 11 is an elbow section), and adjust the length of the fixture fixture 5 according to the length of the draw-in groove 110 at the same time. Insert a plurality of clamp fixtures 5 so as to ensure that the length of all clamp fixtures 5 in the specimen fixture 12 and the draw-in groove 110 is the length of the draw-in groove 110, and at the same time make the fi...

Embodiment 2

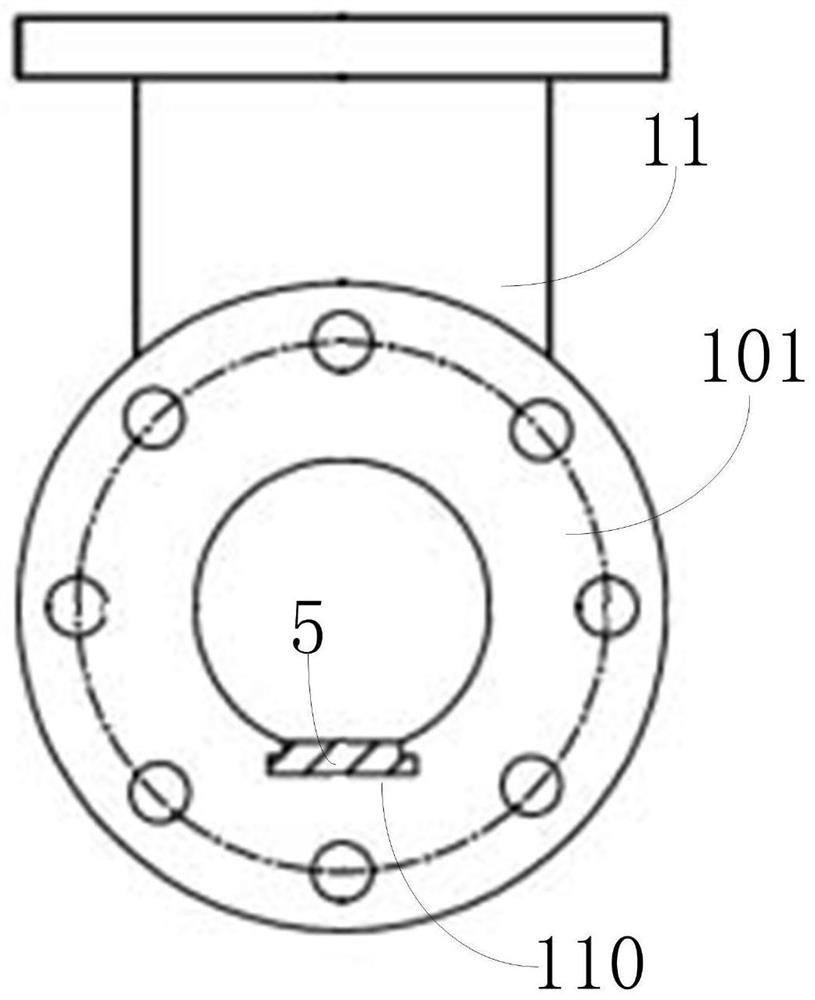

[0119] Embodiment 2: the present invention provides a kind of simulated pipe flow erosion corrosion test device, the working principle of the simulated test of the constant angle of the test pipe fitting sample is as follows:

[0120] Cut out a plurality of small pieces from the pipeline for transporting fluid medium in actual working conditions as a plurality of test pipe fitting samples, and fix the plurality of test pipe fitting samples one by one on a plurality of horizontal test piece fixing fixtures 13, and then fix the horizontal test piece The clamp 13 is clamped in the slot 110 provided on the inner wall of the test pipeline section 11 (the test pipeline section 11 is a straight pipe section), and at the same time, the length of multiple clamp fixtures 5 is adjusted according to the length of the slot 110, so as to ensure that the specimen is fixed. 12 and the length of all clamp fixtures 5 in the draw-in groove 110 are the length of draw-in groove 110, so that after a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com