Preparation method and production device for moisture-proof and hydrophobic medium-temperature electrical-grade magnesium oxide powder

A magnesium oxide powder, electrical grade technology, applied in the direction of magnesium oxide, etc., can solve the problems of incomplete dispersion and coating of moisture-proof agent, inability to realize efficient utilization of silicone moisture-proof agent, failure to meet high standard requirements, etc., to achieve moisture-proof Excellent hydrophobicity, thin coating of moisture-proof agent, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

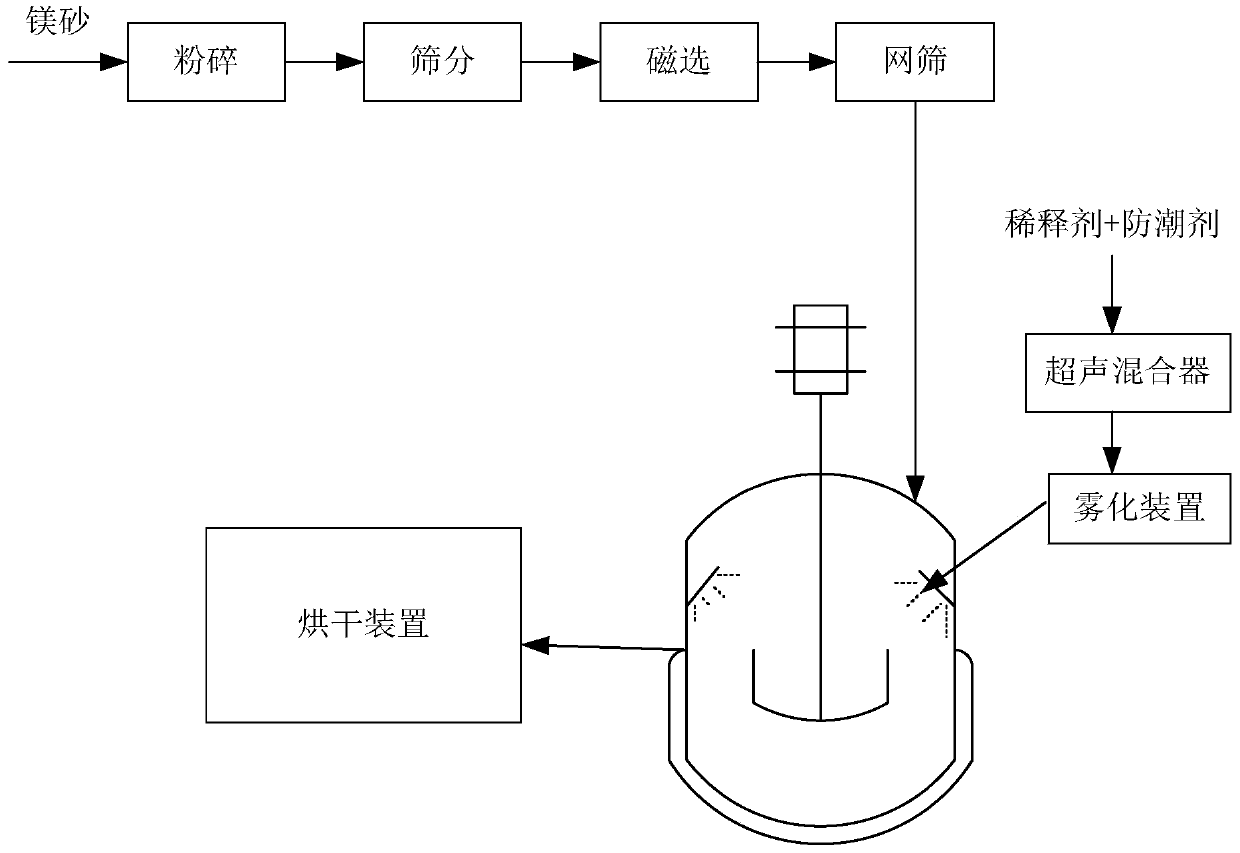

[0021] The invention discloses a preparation method of moisture-proof and hydrophobic medium-temperature electrical grade magnesium oxide powder, which comprises the following steps:

[0022] Step S1: Prepare an electrical grade magnesium oxide powder base material with a particle size of 50 mesh to 325 mesh. The specific preparation method is as follows: large crystal fused magnesia sand is pulverized, sieved, and magnetically separated to obtain large crystal magnesia powder; sieving machine and / or ultrasonic vibrating sieving machine) to make 50 mesh to 325 mesh electrical grade magnesium oxide powder base material. Other existing preparation methods of any electrical grade magnesia powder base material are also available.

[0023] Step S2: Use the ultrasonic mixing method to uniformly mix the moisture-proof agent and the diluent to prepare the diluted moisture-proof agent. The viscosity of the diluted moisture-proof agent is 50-60 (25°Cmm 2 / s). This viscosity range can...

Embodiment 1

[0035]1) The large crystal fused magnesia sand is pulverized, sieved, and magnetically separated to obtain a large crystal magnesia powder.

[0036] 2) Sieving the large crystalline magnesium oxide powder obtained in step 1) through a vibrating screen to prepare a 50-325 mesh electrical grade magnesium oxide powder base material.

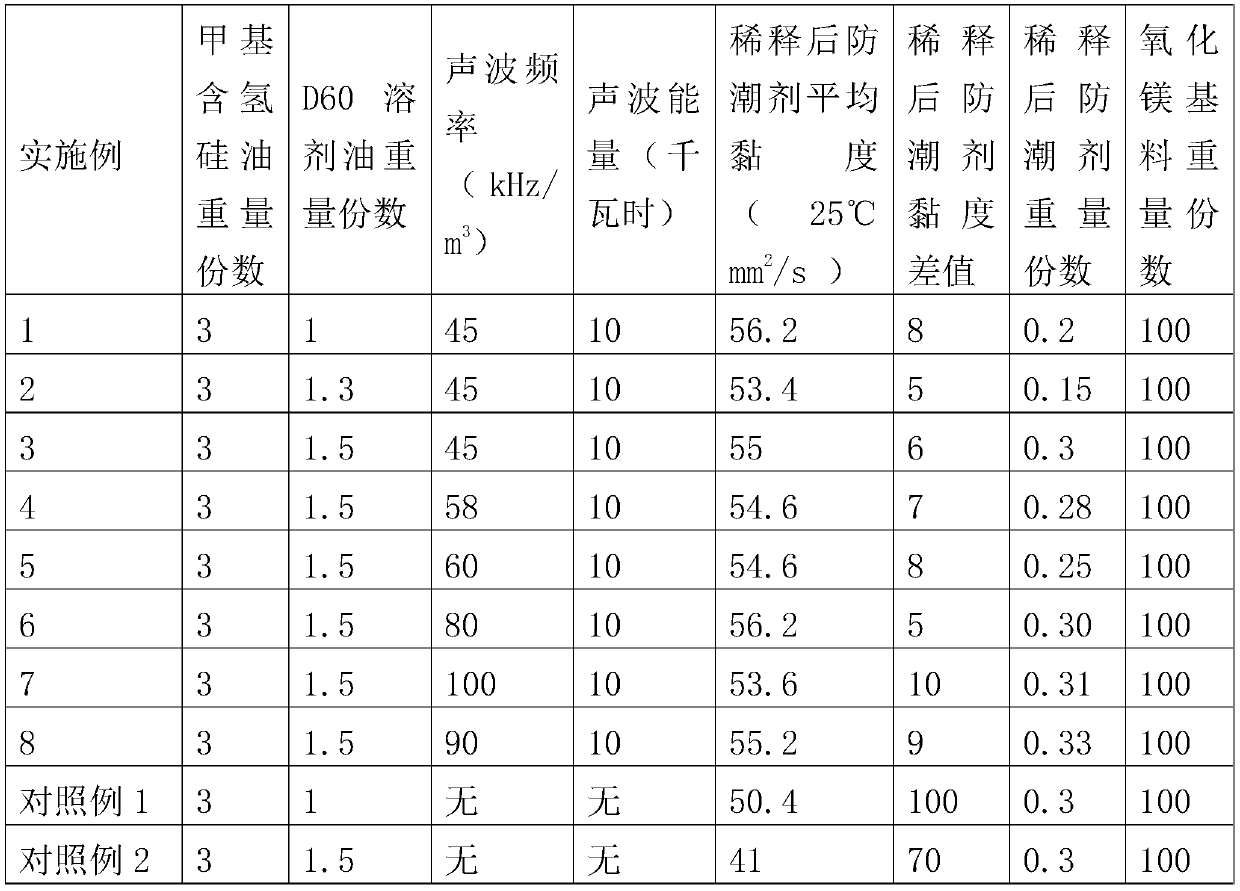

[0037] 3) Put the moisture-proof agent methyl hydrogen-containing silicone oil and D60 solvent oil at a weight ratio of 3:1 and mix them in an ultrasonic mixer for 15 minutes. The frequency range of ultrasonic mixing is 45kHz / m 3 , the energy is 10 kWh, and the diluted methyl hydrogen-containing silicone oil moisture-proof agent is prepared.

[0038] In this example, the hydrogen content of methyl hydrogen-containing silicone oil is ≥5.55 (﹪, m / m), and the viscosity is 500-1000 (25°C mm 2 / s).

[0039] 4) Place the diluted methyl hydrogen-containing silicone oil moisture-proof agent obtained in step 3) in a microwave atomizer, and carry out atomiz...

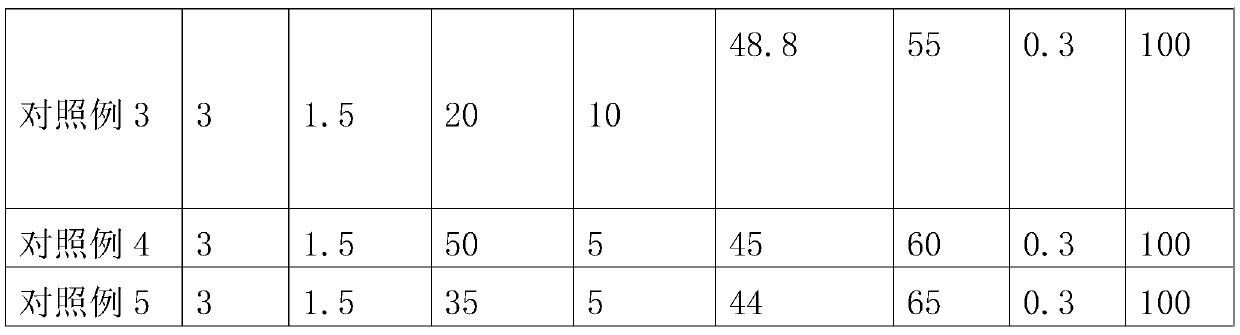

Embodiment 2~8

[0042] Prepared by the same method and steps as in Example 1, changing the weight and number ratio of methyl hydrogen-containing silicone oil and D60 solvent oil, the frequency of sound waves, and changing the weight and number ratio of the diluted moisture-proof agent and magnesium oxide base material, and the remaining parameters All unchanged, the finished product moisture-proof magnesium oxide was obtained. The parameters of the reaction are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com