Placing rack for photovoltaic laminated part

A photovoltaic layer and rack technology, applied to internal accessories, rigid containers, containers, etc., can solve the problems of large output, high risk of hidden cracks, long time for front and rear line adjustment, etc., to facilitate turnover and reduce stacking area , The effect of reducing the risk of hidden cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

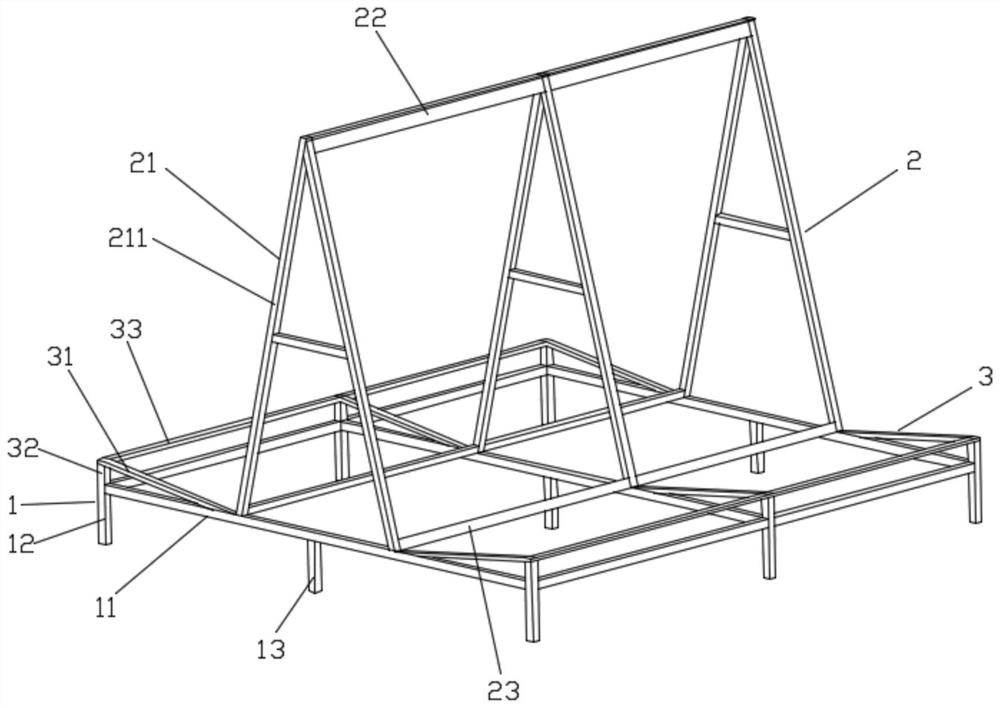

[0020] Such as Figures 1 to 2 As shown, a photovoltaic laminate placing frame includes a bottom frame 1, and a plurality of A-shaped brackets 21 are arranged side by side on the bottom frame 1. The rod 23 is fixed, and the two sides of the A-shaped support 21 respectively form side supports 2, and the bottom frame 1 is provided with a bottom support 3 at the lower end of the side supports 2, and the side of the bottom support 3 away from the side supports 2 is higher than the bottom frame 1. The plane, the side support 2 and the bottom support 3 are used to place the photovoltaic laminate, and the angle between them is greater than or equal to 90°.

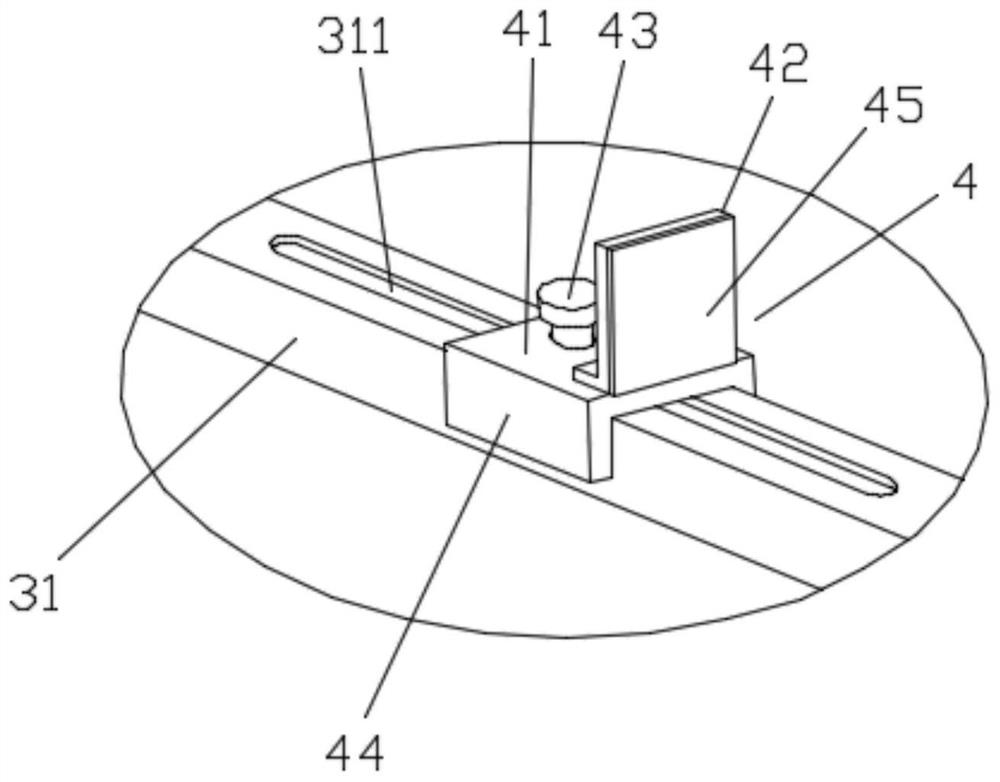

[0021] An A-shaped bracket is arranged on the inner side of the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com