Combined type spray pipe of solid rocket engine

A solid rocket and engine technology, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of expansion ratio and vector control that are difficult to achieve at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described now in conjunction with accompanying drawing:

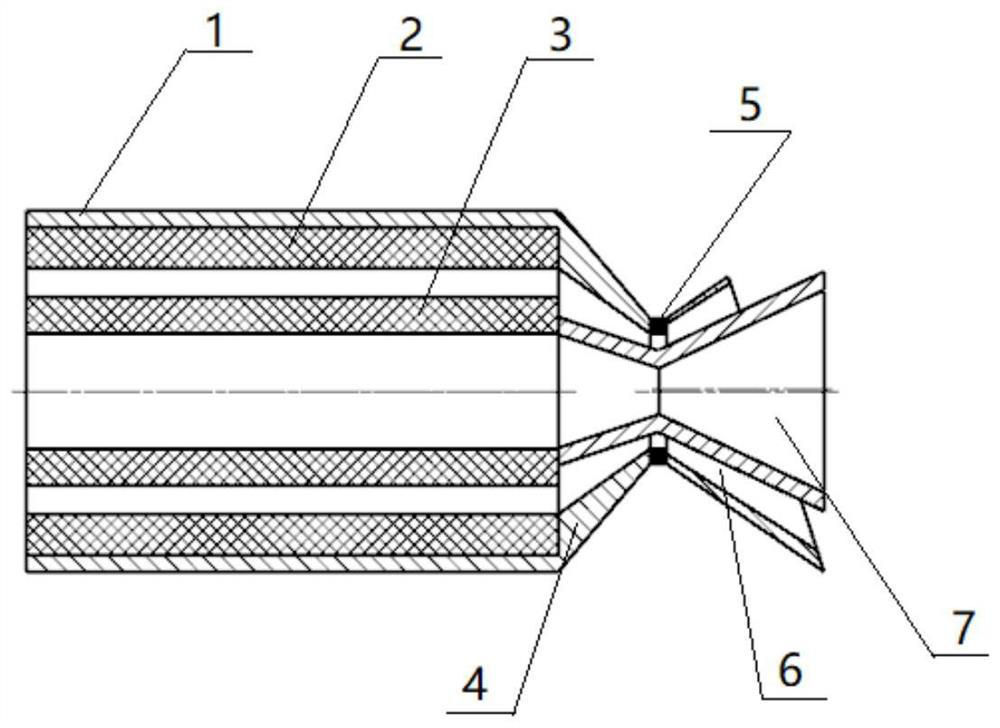

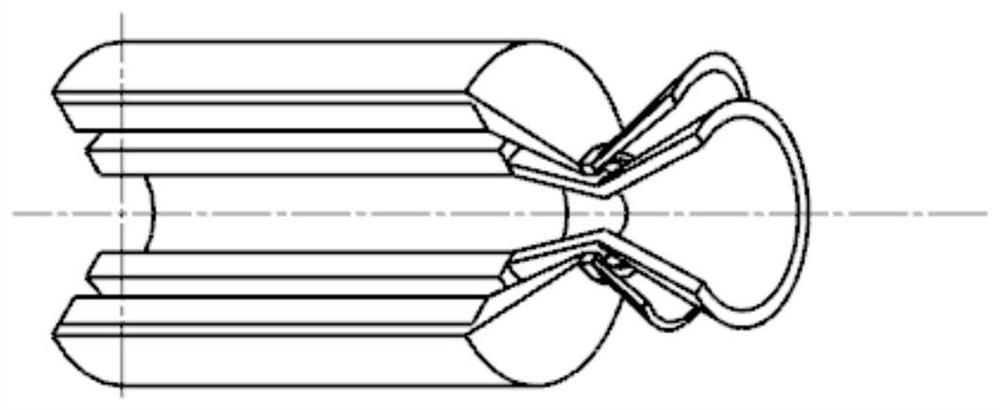

[0020] combine figure 1 , the invention provides a combined nozzle of a solid rocket motor capable of generating vector thrust while ensuring the maximum expansion ratio.

[0021] Specific process:

[0022] The design limit boundary is certain, and the nozzle in this invention adopts the form of a combination of a single-slope expansion nozzle and a Laval nozzle 7 . The outer ring tubular charge 2 burns, and the gaseous combustion products flow from the outer ring gas channel to the converging section 4 of the single-slope expansion nozzle, which is fixed and connected to the wall 1 of the combustion chamber to play a stabilizing role; They are connected by a flexible joint 5, so that the expansion section 6 of the single-slope expansion nozzle can swing within a certain angle range, thereby changing the exhaust direction of the high-sonic gas, generating vector thrust in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com