Method for the 3D printing of two-component polyurethane compositions

A two-component polyurethane, 3D printing technology, applied in the direction of 3D object support structure, additive manufacturing, application, etc., can solve the problems of slowing down 3D printing, limiting printing speed, short service life, etc., to achieve improved mechanical properties and improved The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0127]The preparation of the two components is preferably carried out separately from one another with the exclusion of moisture. The two components are usually stored separately in their own containers. Further constituents of the polyurethane composition may be present as constituents of the first or second component, wherein further constituents reactive towards isocyanate groups are preferably constituents of the first component. Suitable containers for storing the individual components are in particular barrels, bottles, bags, buckets, tanks, cartridges or tubes. Both components are storage-stable, ie they can be stored for several months to a year and longer before use without changing their individual properties to the extent relevant to their use.

[0128] The two components are stored separately from one another prior to mixing the composition and are mixed with one another at or immediately before use. Said components are advantageously present in a package consist...

Embodiment

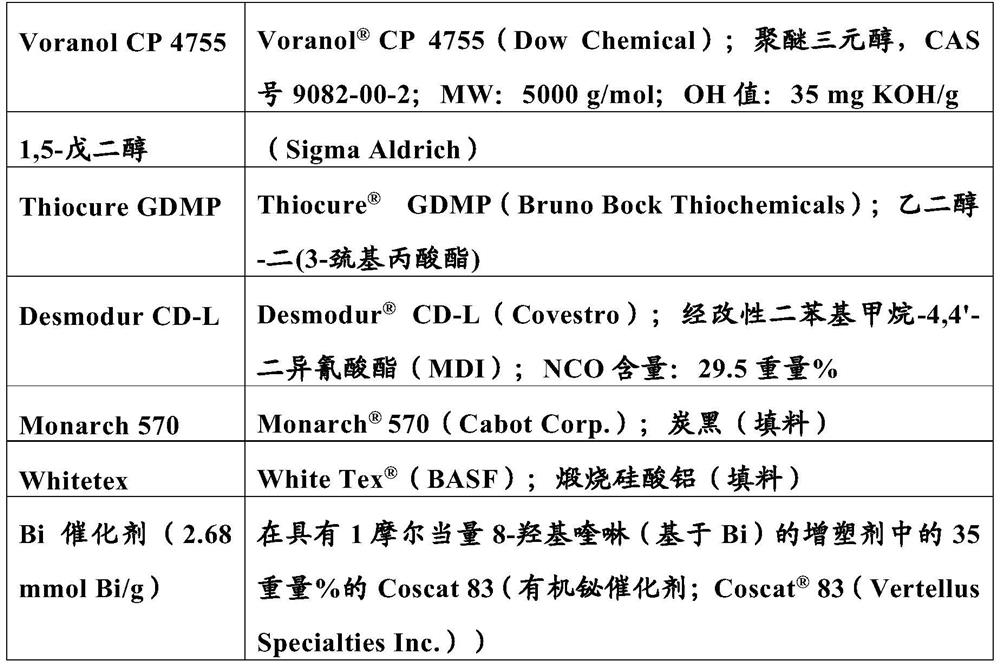

[0167] Substances used:

[0168]

[0169] Table 1: Substances used

[0170]Preparation of Components A and B

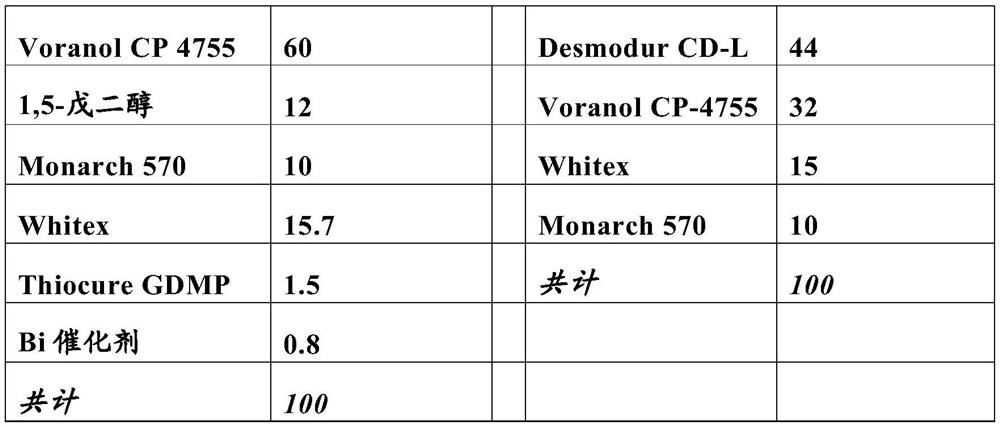

[0171] For each composition, the ingredients of the first component A given in Table 2 below were processed into a homogeneous paste in the given amounts (expressed in parts by weight or % by weight) by means of a vacuum dissolver with the exclusion of moisture And airtight preservation. Likewise, the ingredients of the second component B given in the table are processed and saved. Each of the two components is filled in one chamber of an airtight double cartridge.

[0172]

[0173]

[0174] Table 2: Two-component polyurethane compositions for 3D printing

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com