Steel sheet and production method therefor

A manufacturing method and technology of steel plates, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of uneven structure and material, and achieve the effect of preventing large-scale collapse and excellent brittle crack propagation stop characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

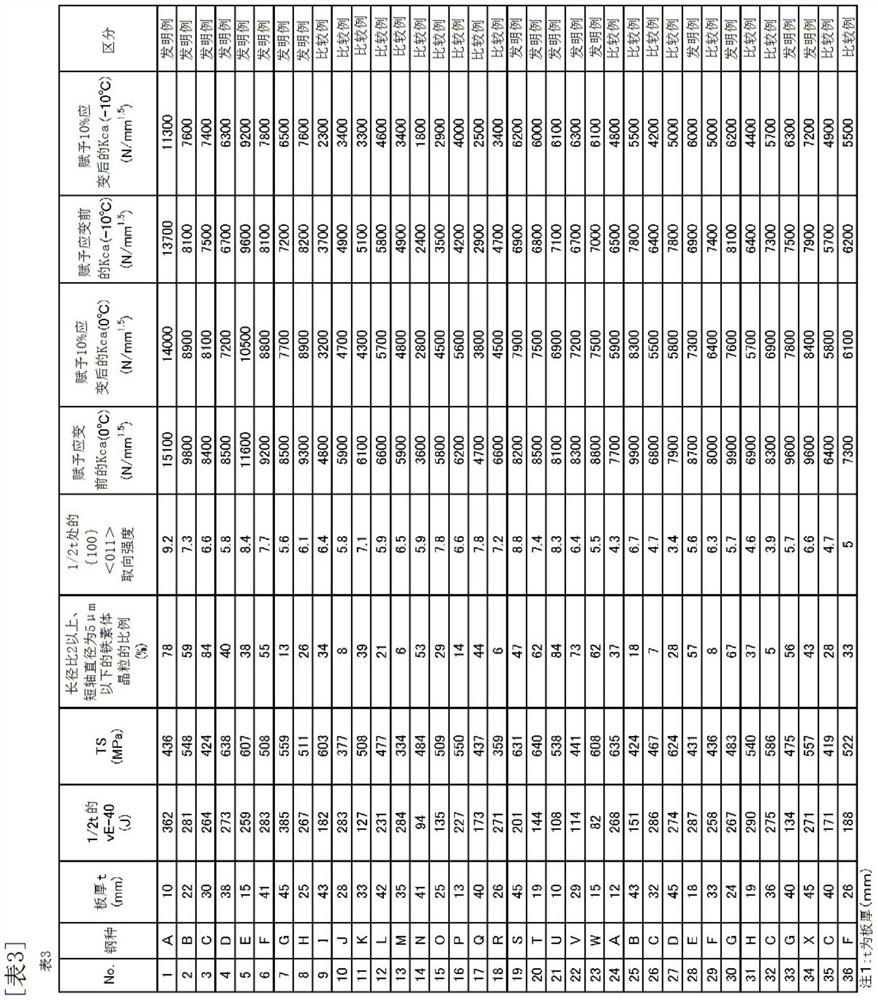

[0134] Examples (including comparative examples departing from the scope of the invention) of steel sheets produced according to the present invention and having good brittle crack propagation stopping properties even after being subjected to plastic deformation are shown below.

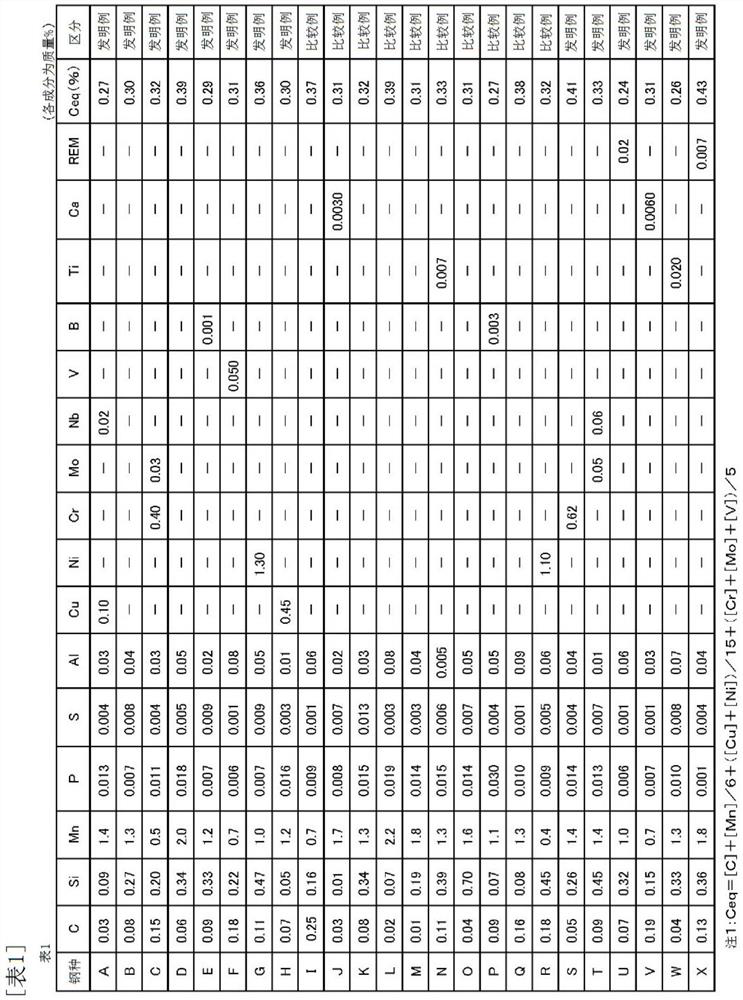

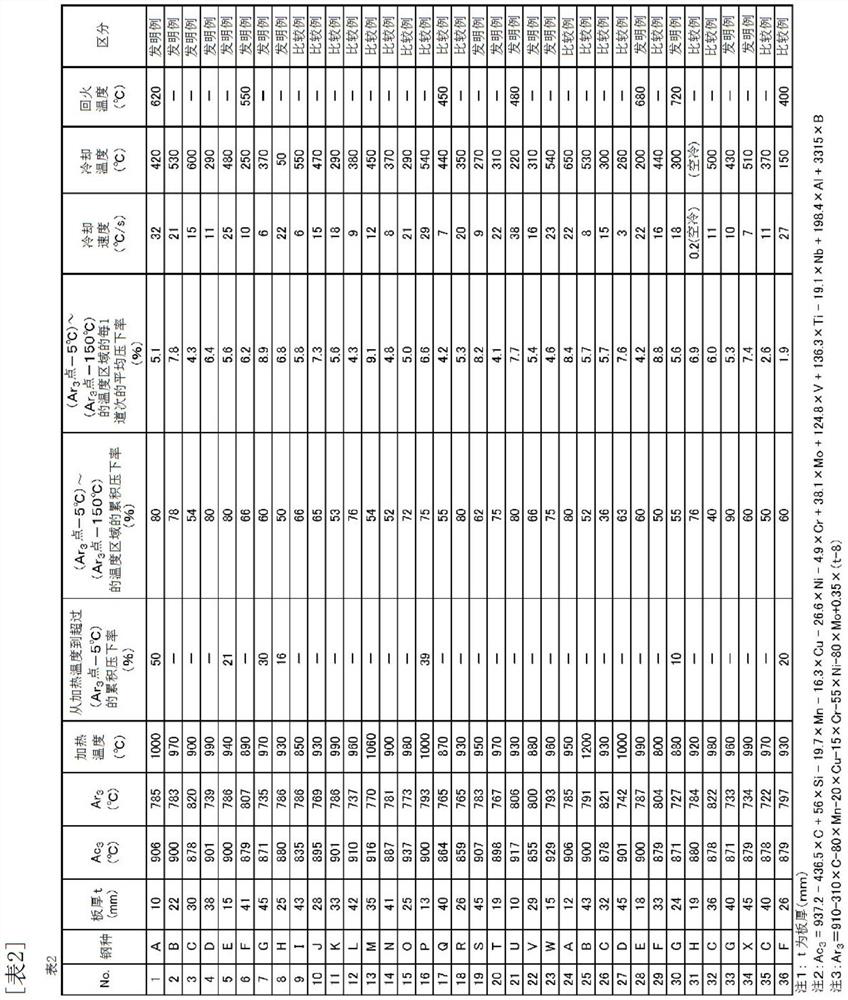

[0135] Table 1 shows the chemical composition of the test steels. Hot rolling was performed to produce steel sheets with a thickness of 10 to 45 mm from steel slabs having these chemical components, and properties of the obtained steel sheets were evaluated. Table 2 shows the manufacturing conditions of the test steel sheets. Ac obtained by calculation is also shown in this table 3 point and Ar 3 point temperature.

[0136]

[0137]

[0138] The toughness, tensile strength, texture, ratio (area ratio) of ferrite grains with an aspect ratio of 2 or more and a minor axis diameter of 5 μm or less, and brittle crack propagation stop characteristics of the obtained steel sheets were evaluated by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com