Welded structure with excellent brittle crack propagation stop characteristics

A technology of brittle crack propagation and stop characteristics, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problem of high safety assurance, and achieve the effect of ensuring safety and excellent brittle crack propagation stop characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0097] Hereinafter, the present invention will be described in detail based on examples.

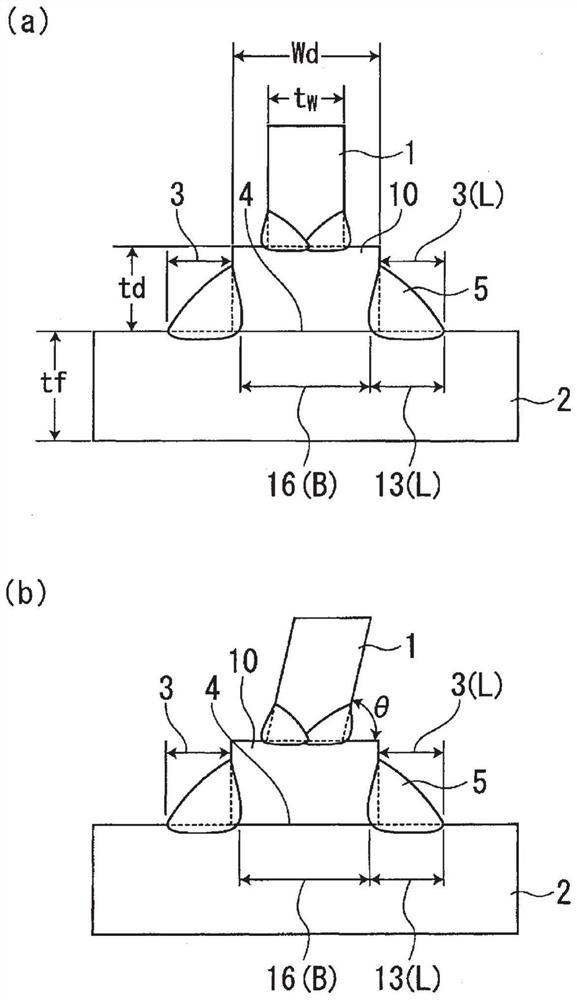

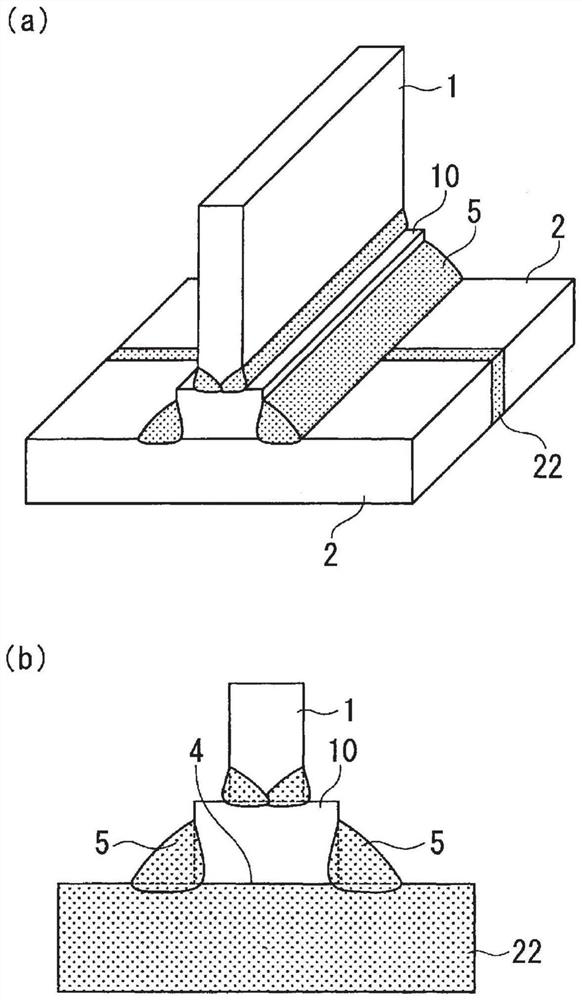

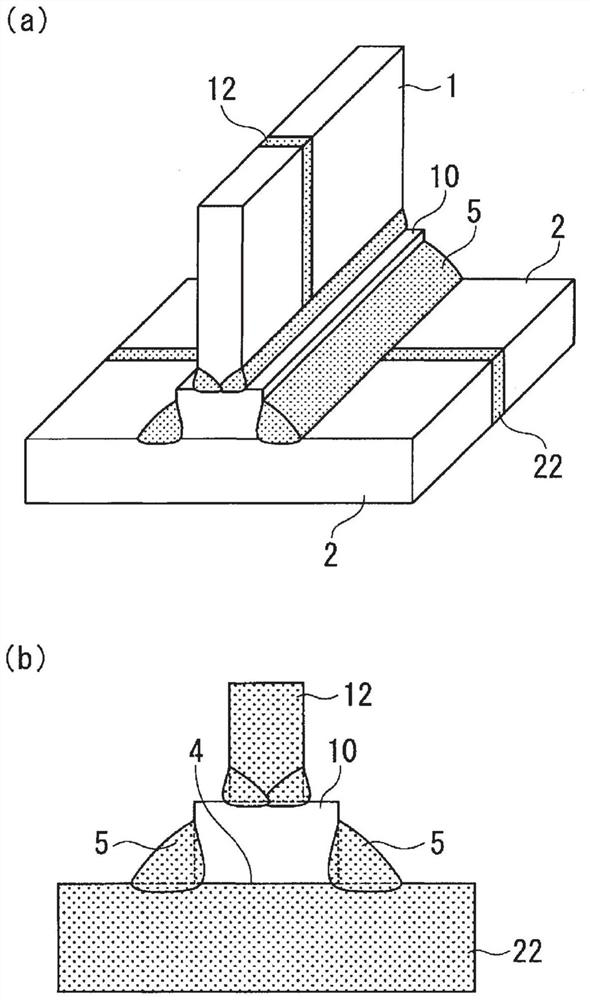

[0098] Using thick steel plates with the plate thicknesses shown in Table 1-1 and Table 1-2 as joining members (webs), doubling members and members to be joined (flanges), manufactured Figure 4 (a), (b), (c) and Figure 5 Large welded structural joints of actual structural dimensions in shapes shown in (a), (b), and (c). Figure 4 (a), (b), and (c) are diagrams assuming the occurrence / propagation of brittle cracks from the member to be joined (flange), Figure 5 (a), (b), and (c) are diagrams assuming a case where a brittle crack occurs / propagates from a joint member (web). It should be noted that, in the manufactured fillet joint, the ratio Y of the unwelded portion (=(width B of the unwelded portion / plate width of the doubled member Wd)) changes and exists figure 1 (a) Unwelded portion 4 as shown. It should be noted that no unwelded portion remained on the butt surface of the joi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com