High-strength steel plate for high heat input welding excellent in brittle crack propagation stop characteristic and manufacturing method thereof

A technology of brittle crack propagation and large line energy welding, applied in the field of high-strength steel plates, can solve the problem of difficult control of production scale, and achieve the effect of excellent brittle crack propagation stop characteristics and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

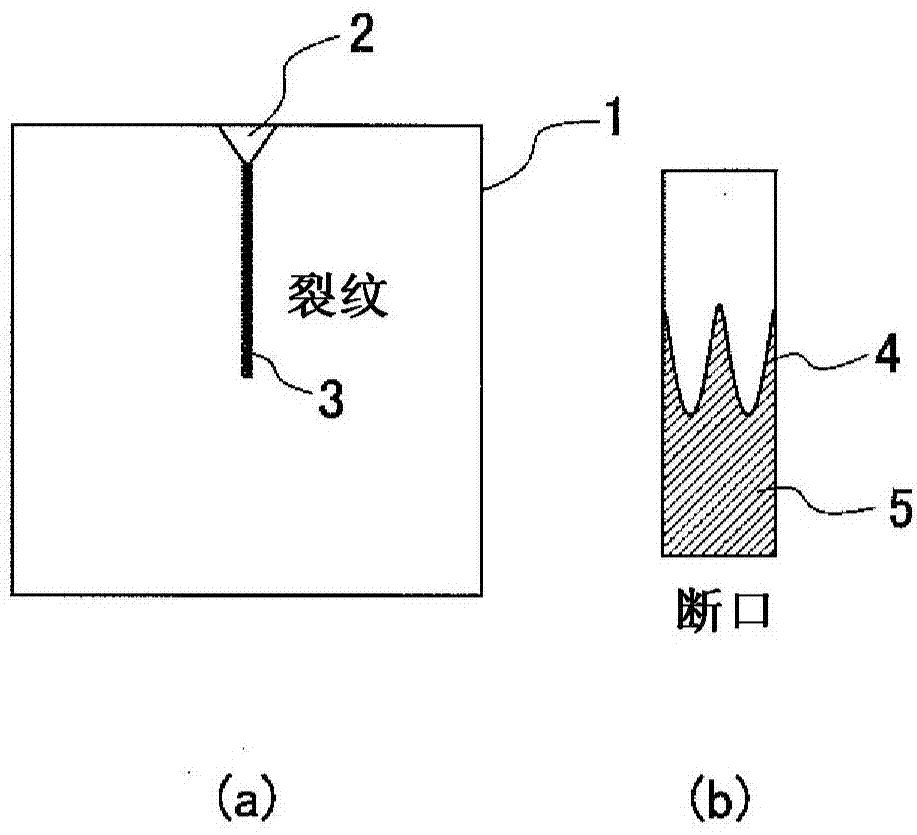

Image

Examples

Embodiment

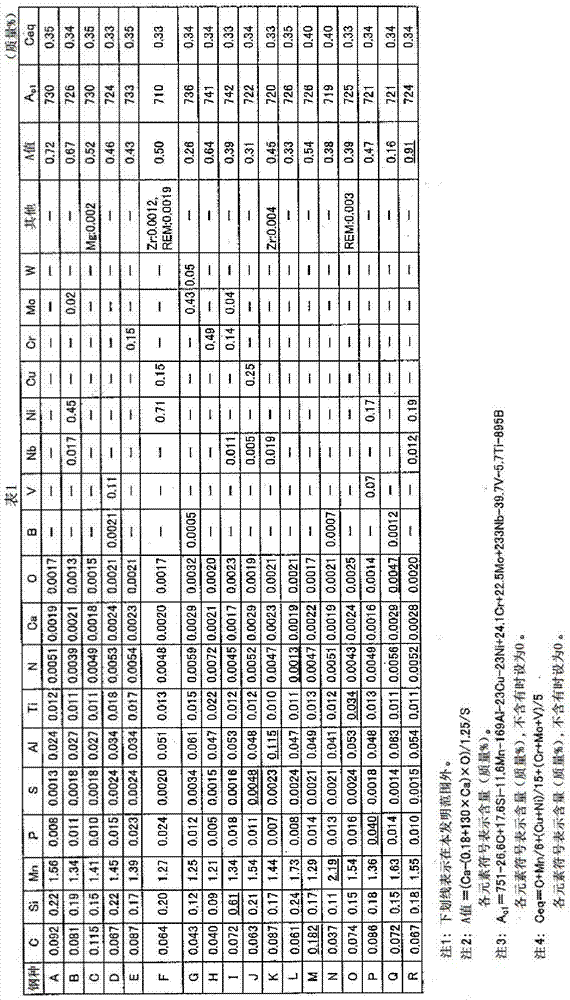

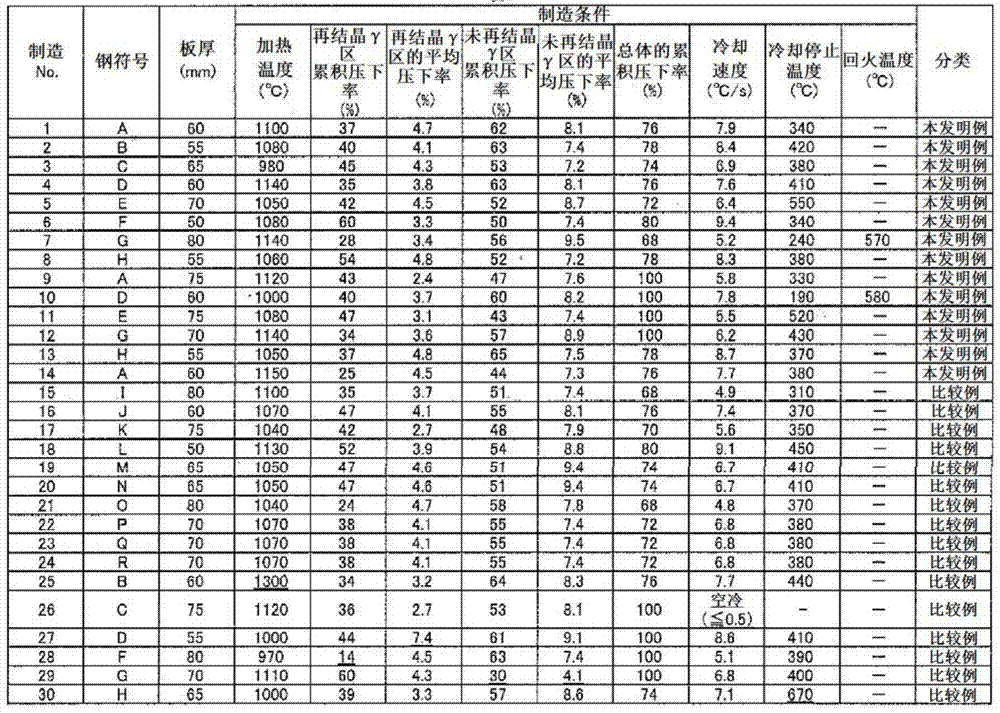

[0138] The molten steel (steel codes A to R) of each composition shown in Table 1 is smelted in a converter, and made into a steel raw material (slab thickness 250 mm) by continuous casting, hot rolled to a plate thickness of 50 to 80 mm, and then cooled. The test steels No. 1-30 were obtained. For some, tempering was also performed after cooling. Table 2 shows hot rolling conditions, cooling conditions, and tempering conditions.

[0139]

[0140] Table 2

[0141]

[0142] Note 1: The underline indicates that it is outside the scope of the present invention.

[0143] Note 2: "Cumulative reduction rate in the recrystallization γ zone" refers to the cumulative reduction rate in the central part of the plate thickness in the state of the austenite recrystallization temperature range.

[0144] Note 3: "Average reduction ratio in the recrystallization γ region" refers to the average reduction ratio per pass in the state where the central part of the plate thickness is in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com