Equipment in high-temperature ceramic sintering furnace

A technology of high-temperature ceramics and sintering furnace, which is applied in the field of high-temperature structural ceramics and can solve problems such as depressions and the influence of ceramic surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Figure 1 to Figure 6 Shown:

[0029] The invention provides a high-temperature ceramic sintering furnace equipment,

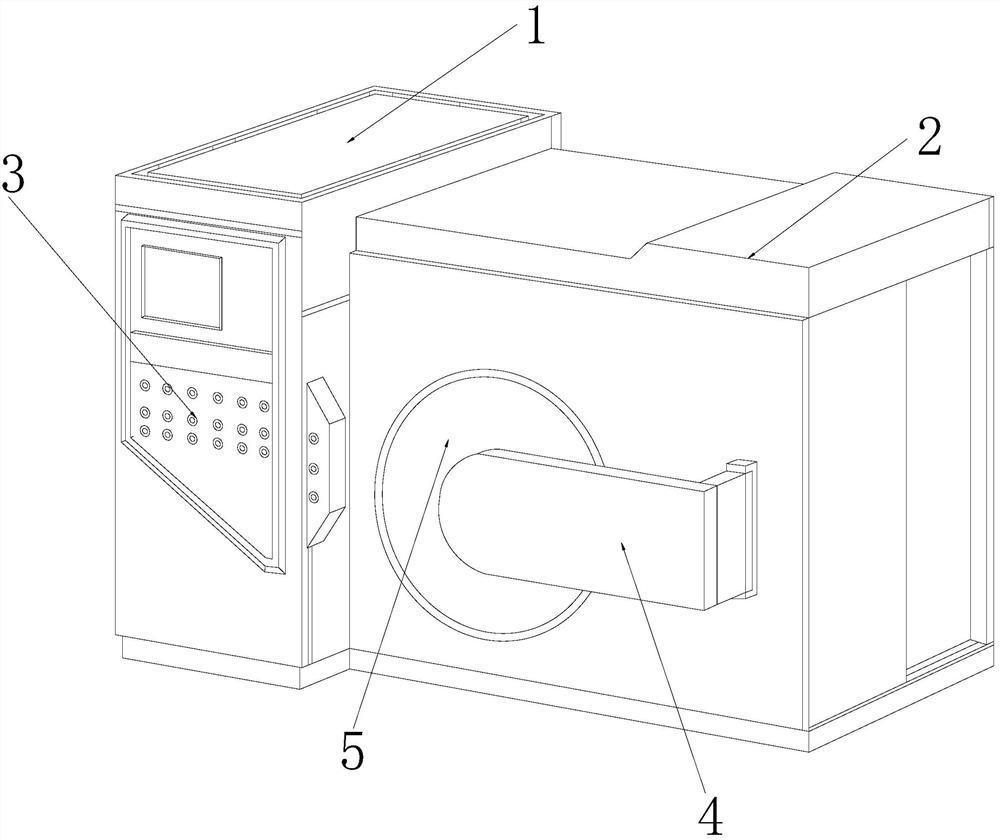

[0030] Its structure includes an electric control box 1, a furnace 2, a control terminal 3, a switch board 4, and a material inlet 5. The side of the electric control box 1 is electrically connected to the furnace 2, and the control terminal 3 is installed on the electric control On the end surface of the box 1 , the switch plate 4 is embedded in the front of the furnace 2 , and the material inlet 5 is movably connected with the switch plate 4 .

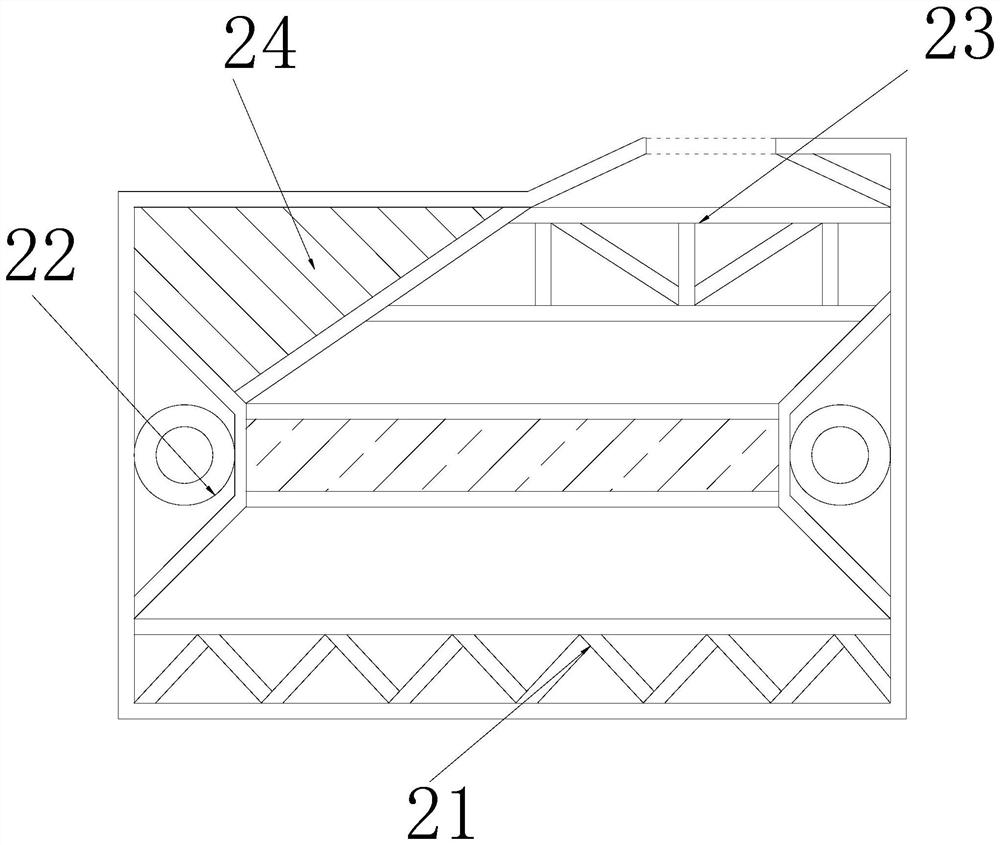

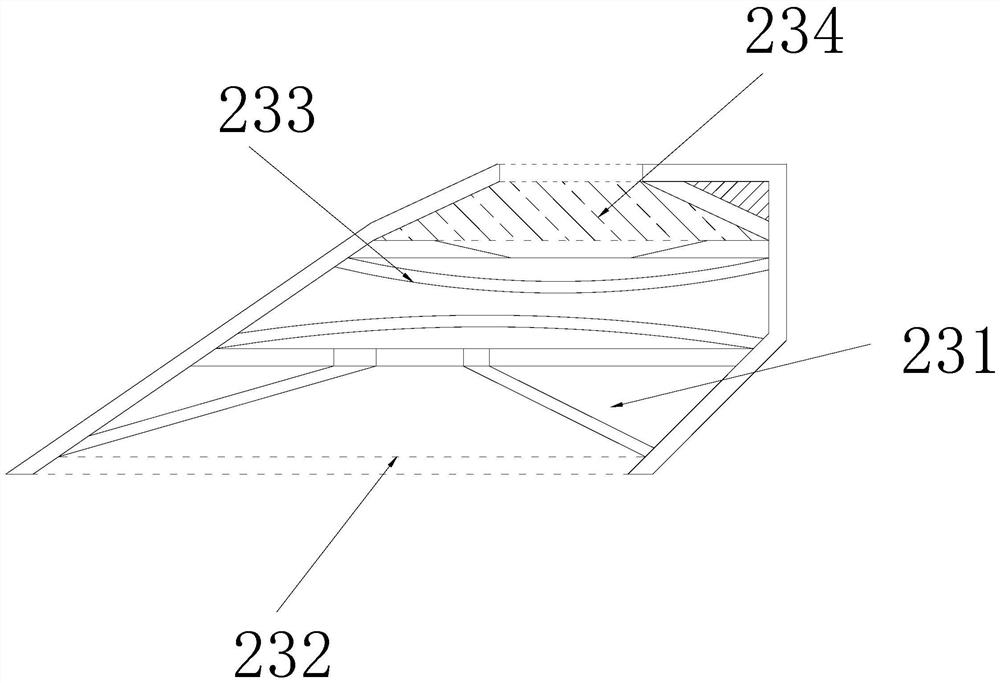

[0031] The sintering furnace 2 is provided with a forming table 21, a sintering device 22, a collecting device 23, and a fixed end 24. The sintering device 22 is installed above the forming table 21, and the collecting device 23 is installed above the side of the sintering device 22. The fixed end 24 is fixedly connected with the collecting device 23, the inside of the fixed end 24 is in a solid state, and i...

Embodiment 2

[0039] Figure 7 to Figure 9 Shown:

[0040] The invention provides a high-temperature ceramic sintering furnace equipment,

[0041] Its structure includes that the spray grid a4 is provided with a channel a41, a fixed box a42, and a filter layer a43, and the inner sides of the channel a41 are fixedly connected with the fixed box a42, and the filter layer b43 is embedded in the fixed box a42. The filter layer a43 is equipped with a multi-layer filter system, and the filter layer a43 can effectively isolate most impurities in the gas through its internal multi-layer filter, so that the finally discharged gas is clean gas.

[0042] Wherein, the fixed box a42 is provided with a bonding plate c1, a frame c2, a contact end c3, a fixing grid c4, and a spring c5, the side of the bonding plate c1 is integrated with the frame c2, and the contact end c3 is installed on the frame c2. At the upper end, the fixed grid c4 is embedded in the side of the contact end c3, the spring c5 is mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com