Fiber bragg grating testing method for flow-induced vibration of tube bundle structure

A technology of fiber grating and testing method, which is applied in the testing of machine/structural components, fluid dynamics test, measuring device, etc., can solve the problems of many strain measuring points and complicated test installation procedures, and achieves more measuring points and testing cost. The effect of low and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

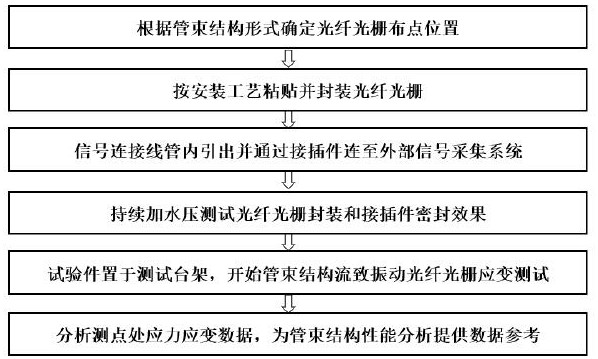

[0026] like figure 1 As shown, a fiber grating test method for flow-induced vibration of a tube bundle structure, the steps are as follows:

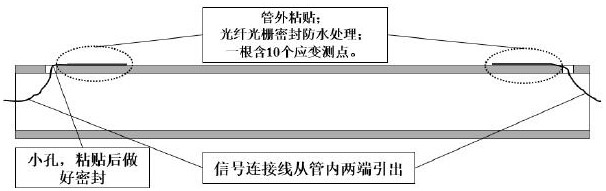

[0027] Step 1. Firstly, according to the structural form and boundary conditions of the tube bundle, determine the location with a higher strain response level of the tube bundle structure. Generally, the fluid inlet and outlet areas and the longer-span tubes have a larger strain response, so it should be selected as the fiber grating layout location, such as figure 2 shown;

[0028] Step 2, according to the selected fiber grating layout position, paste the fiber grating on the outer wall of the test tube in turn, the signal connection line is arranged in the test tube, one end of the signal connection line is drawn from the test tube through the threading hole, connected with the fiber grating, and for encapsulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com