Commutator automatic compression mold device

An automatic compression molding and commutator technology, applied in the field of commutator compression molding molds, can solve problems such as reducing compression molding efficiency, and achieve the effect of improving compression molding efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

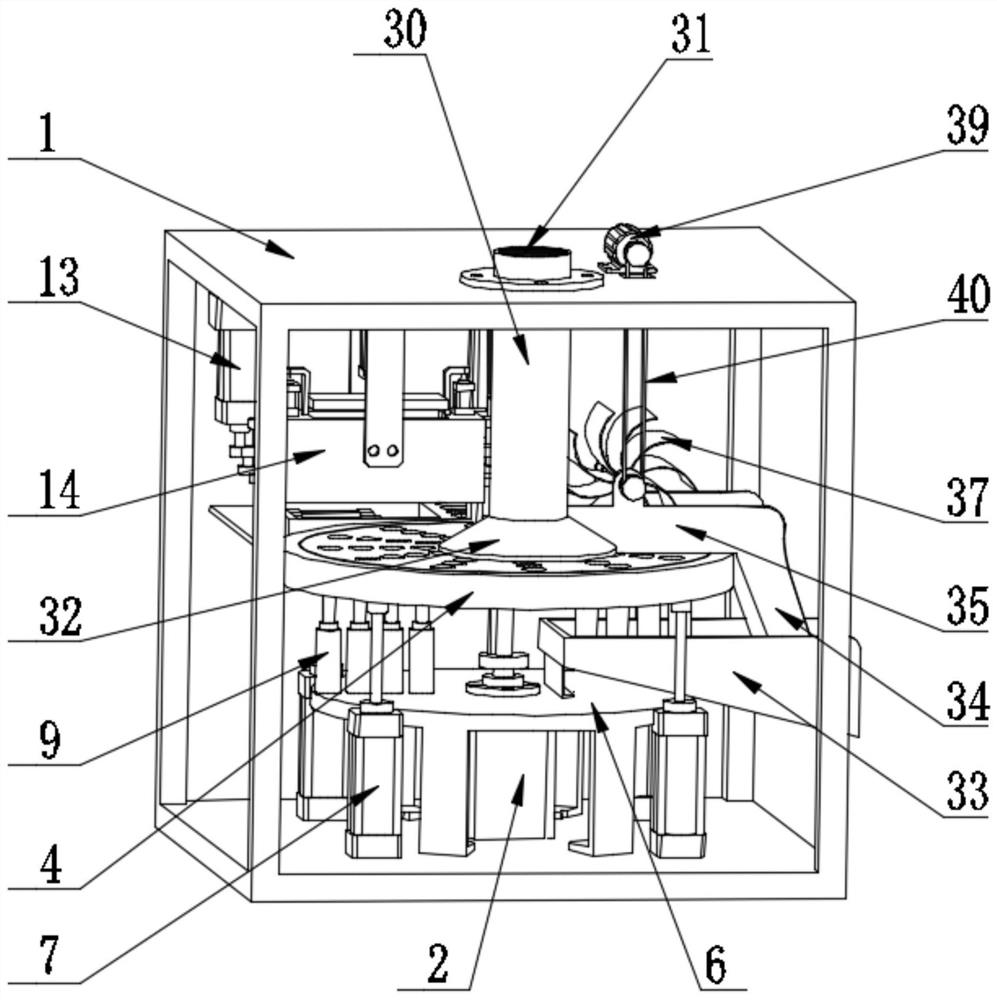

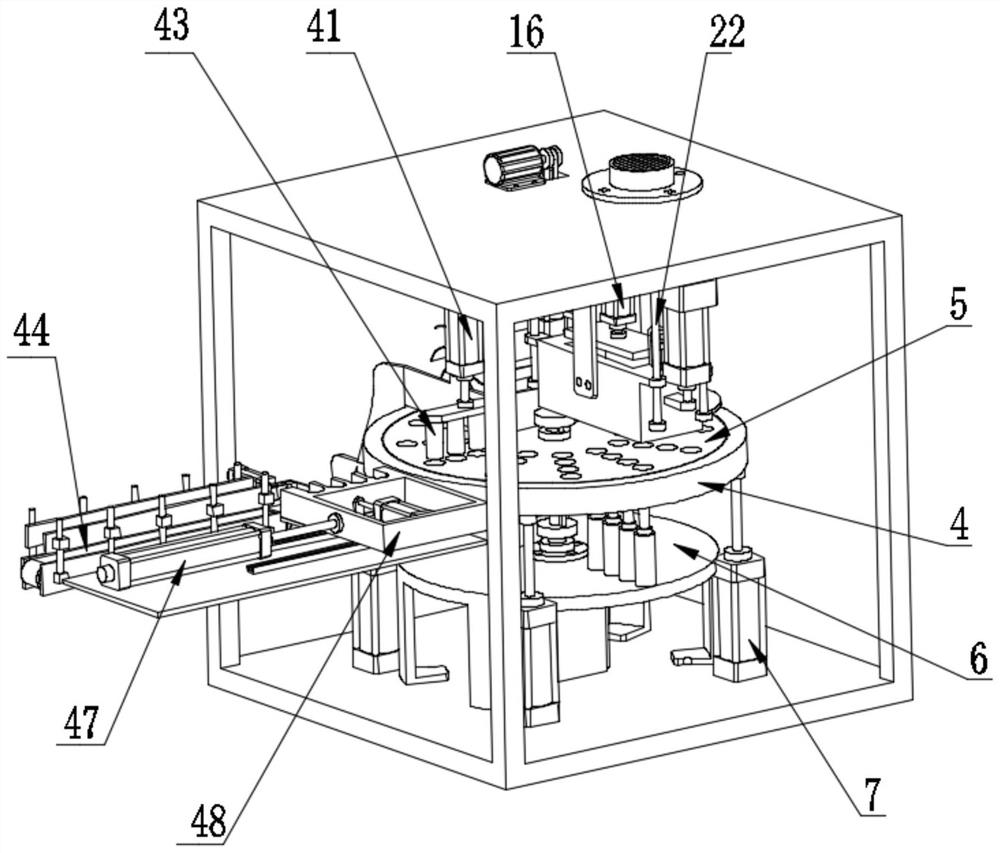

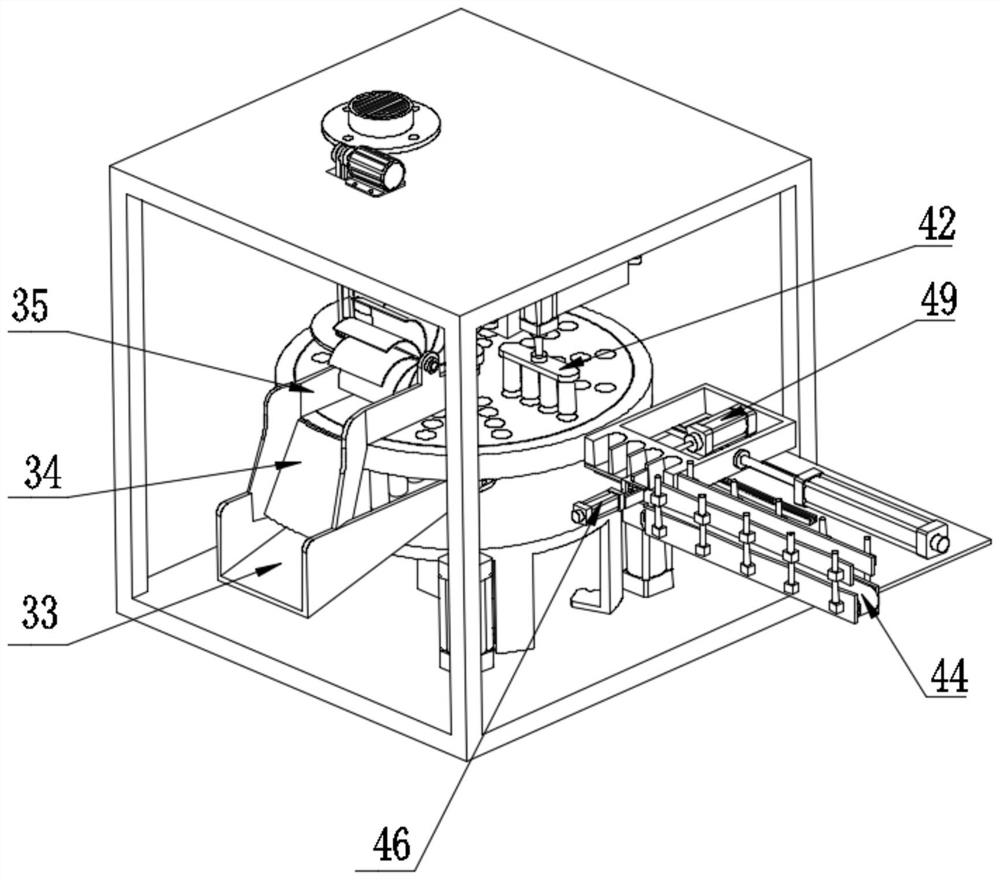

[0054] A kind of commutator automatic compression mold device of the present embodiment, refer to Figure 1-14 : Including the body 1, the inner and lower layers of the middle part of the body 1 are equipped with a transfer compression molding mechanism, which is used to transfer the arranged commutator segment group, transfer the wire change segment group to the compression molding station and perform compression molding into finished products, and transfer the finished products in sequence To the air cooling station and the discharge station;

[0055] The upper left part of the body 1 is equipped with an injection molding mechanism, which is used to inject the hot-melt plastic matrix into the compression molding station to form a finished product;

[0056] An air-cooling mechanism is installed in the upper layer of the front part of the body 1, which is used to cool the finished product by air cooling;

[0057] The middle and lower layer of the right part of the body 1 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com