Automatic checking device for magnetic turning plate liquid level meter and use method

A magnetic flap liquid level and automatic calibration technology, applied in the field of instrument calibration, can solve problems such as poor accuracy, long time consumption, and cumbersome steps, so as to improve reliability, reduce the risk of equipment damage, and avoid calibration blind spots Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

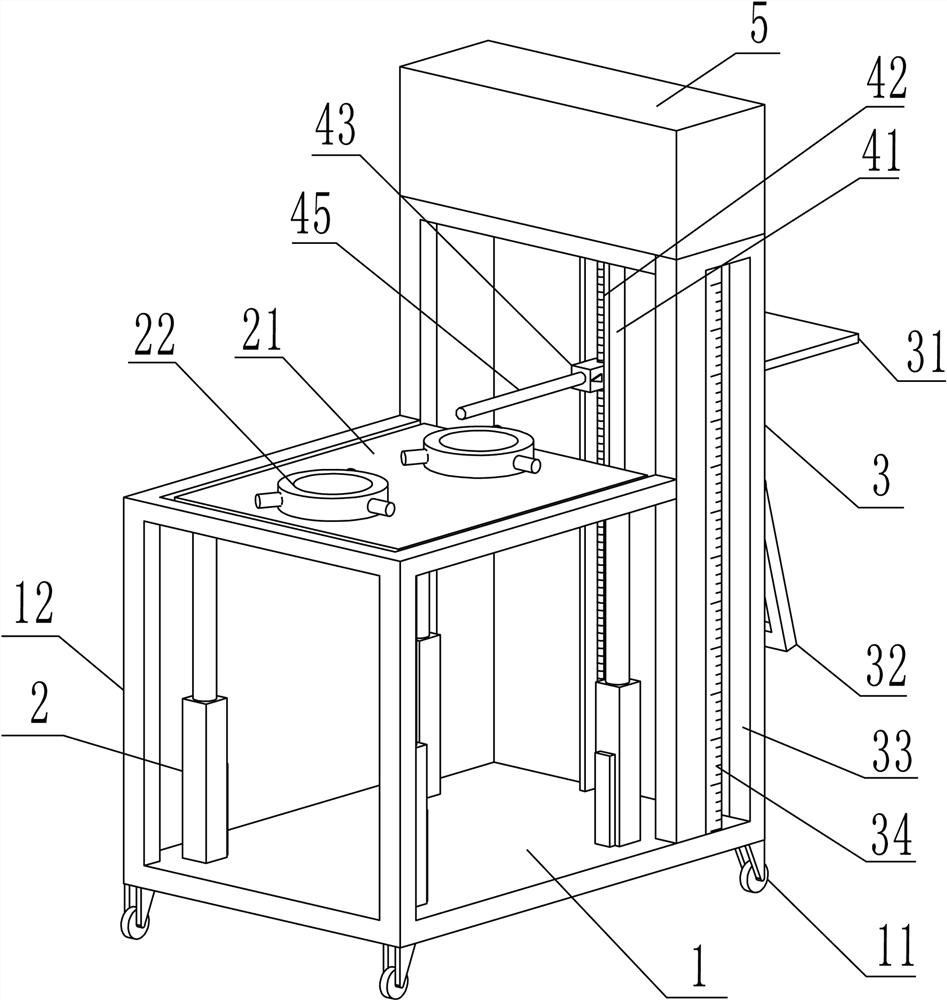

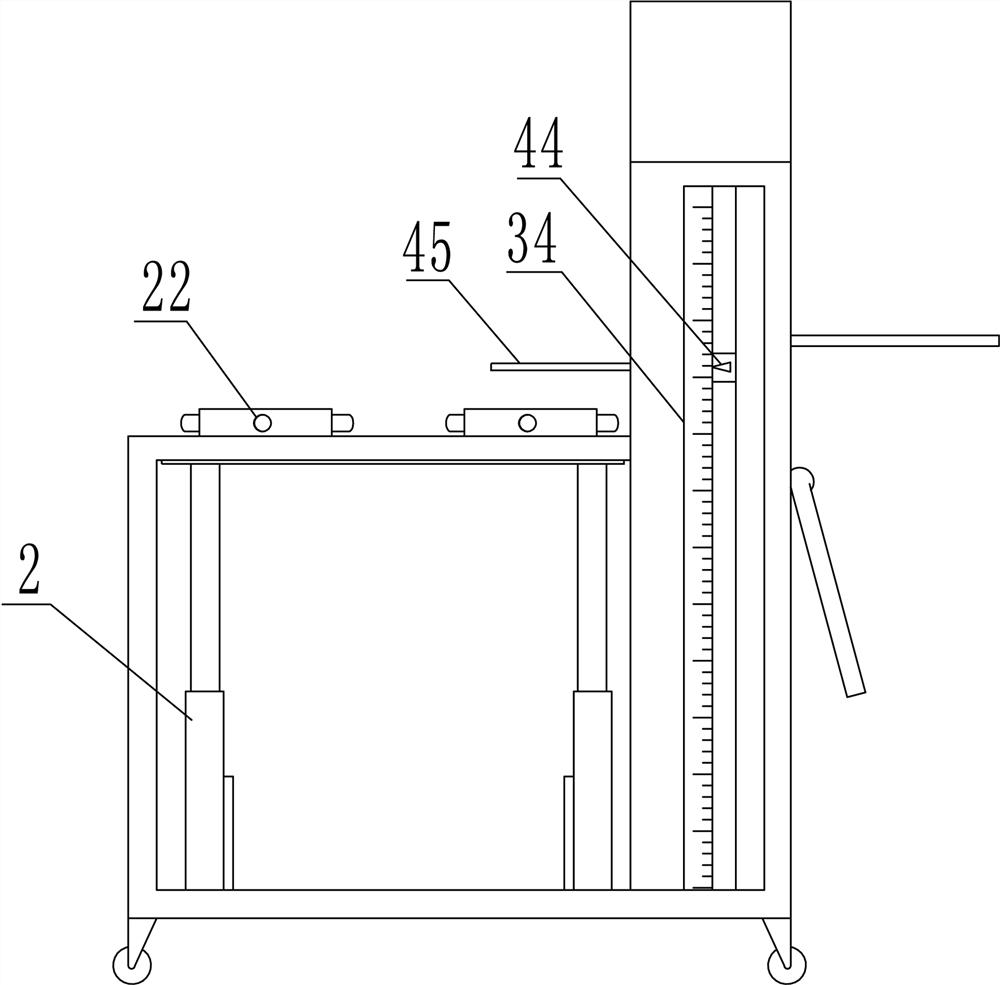

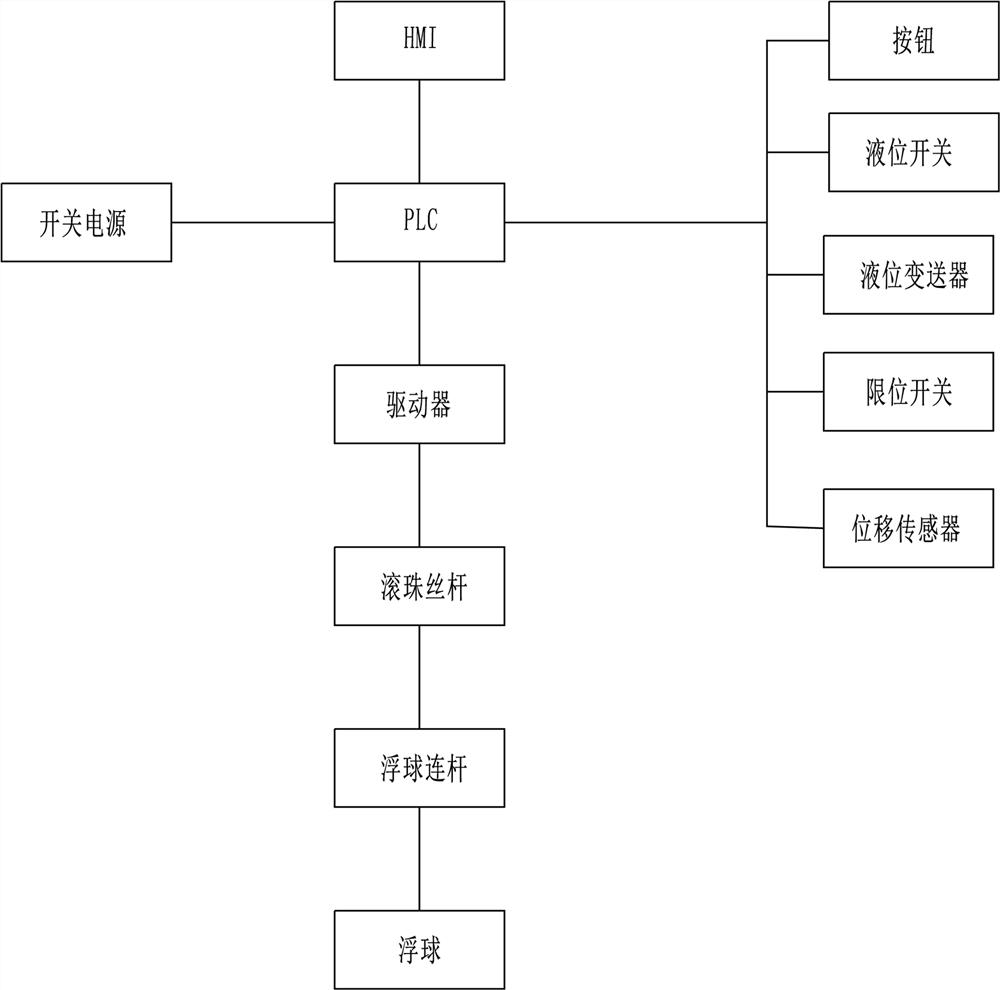

[0042] Such as Figure 1 ~ Figure 3 Among them, an automatic calibration device for a magnetic flap liquid level gauge, including a bottom plate and a universal wheel below the bottom plate; a support frame connected to a frame structure on the upper surface of the bottom plate; multiple electric push rods connected to the upper surface of the bottom plate in the support frame, The telescopic end of the electric push rod is connected upward to the lifting platform, and the upper surface of the lifting platform is connected with multiple chucks to cooperate with the magnetic flap level gauge; the upper surface of the bottom plate on one side of the support frame is connected to a side box, and the inner wall of the side box is connected to a lifting mechanism ; The top of the side box is connected with the equipment box.

[0043] Further, the chuck is a three-jaw chuck; the outer surface of the three-jaw chuck is provided with a threaded hole, and a screw rod is arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com