Whole vehicle short-mileage NVH verification method

A verification method and mileage technology, applied in the automotive field, can solve problems such as failure to complete, program change, cycle and cost increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

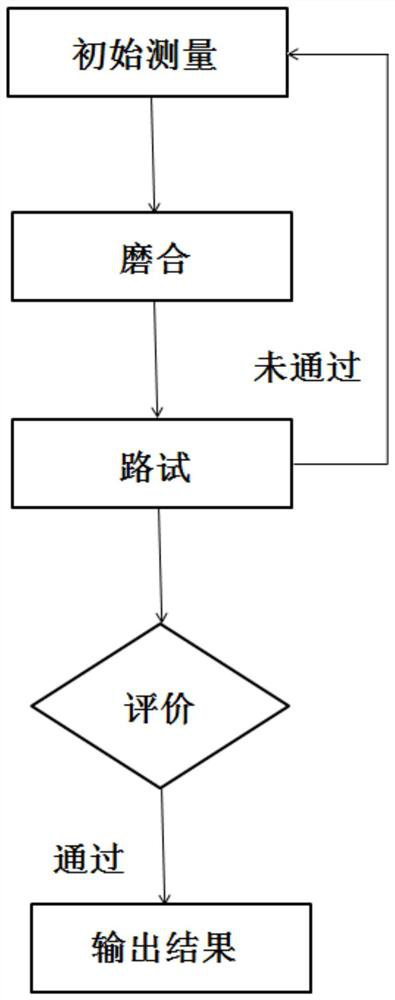

Method used

Image

Examples

Embodiment

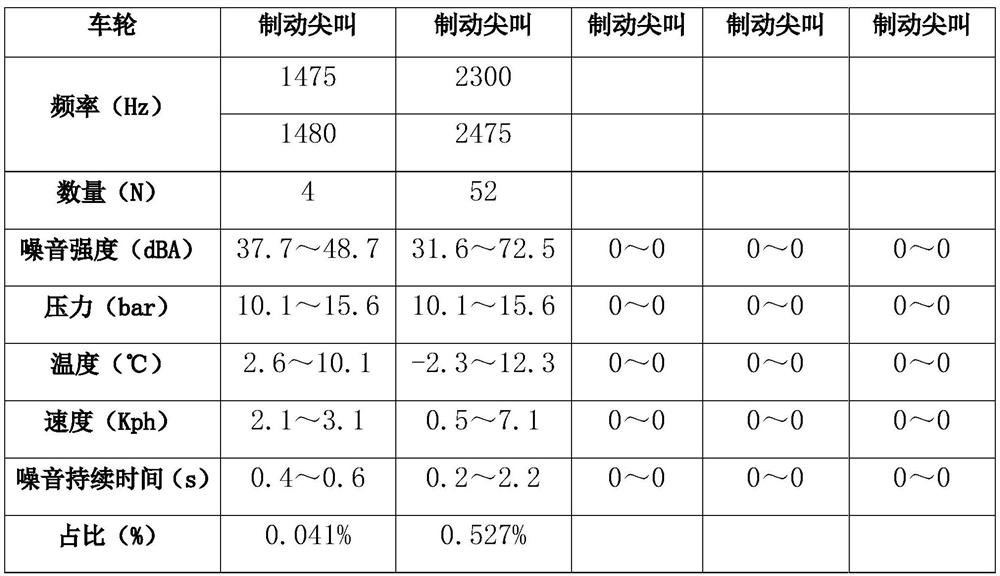

[0036] In a certain project development process, the vehicle short mileage NVH verification method of the present invention is adopted, and the specific data are as follows under each working condition:

[0037] Total braking times: 9871

[0038]

[0039] In summary, 1500hz and 2400hz low-temperature noises have been successfully verified, and the noise occurrence probability exceeds 3‰. Therefore, it is necessary to optimize the noises and provide a data basis for subsequent optimization schemes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com