Light-absorbing flange lenses

A flange and refraction lens technology, applied in the direction of lens, optics, prism, etc., can solve the problems of low resolution and low image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

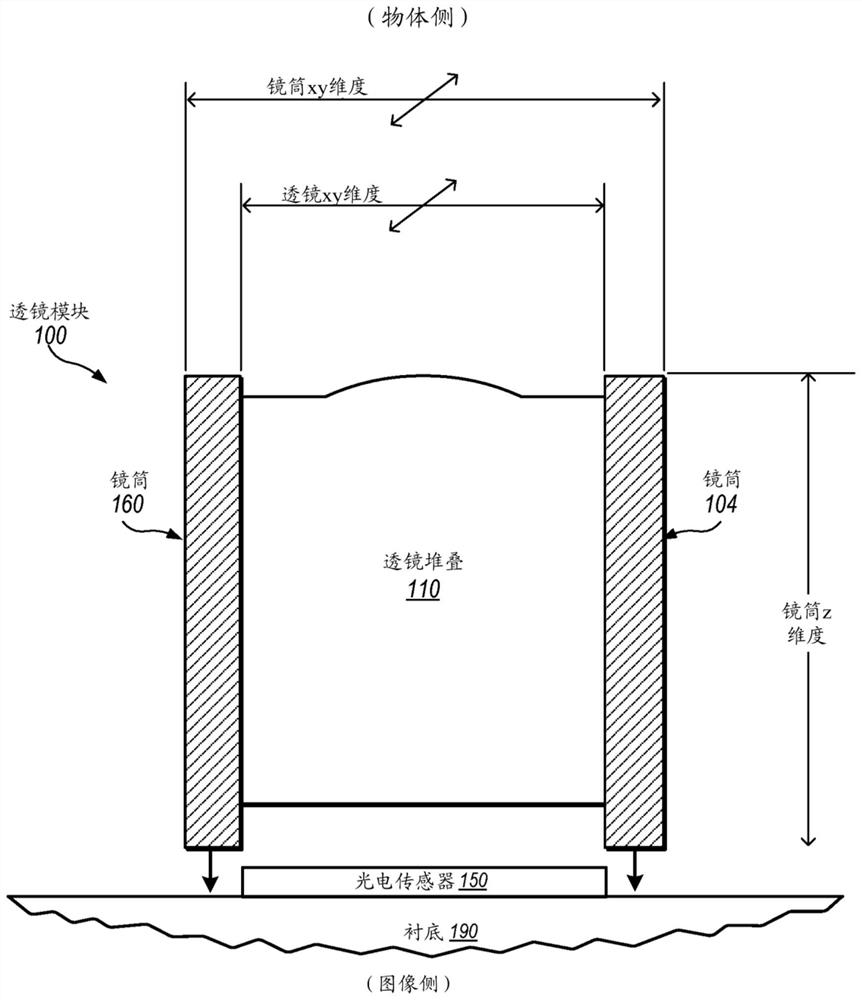

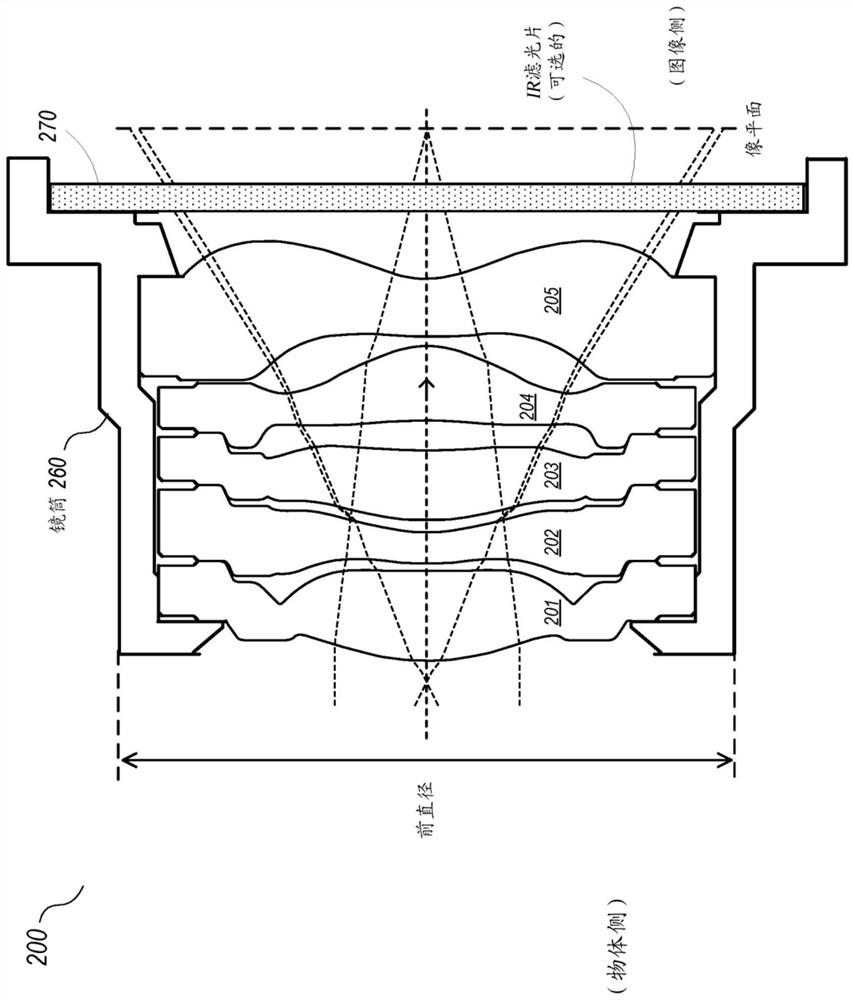

[0033] Embodiments of compact lens systems (which may also be referred to as lens systems) are described herein, which may include one or more refractive lens elements (referred to as lens stacks). Embodiments of the compact lens system can be used in cameras with a small package size (referred to as small format factor cameras). Embodiments of small format factor cameras are described herein, including but not limited to implementations of photosensors and compact lens systems.

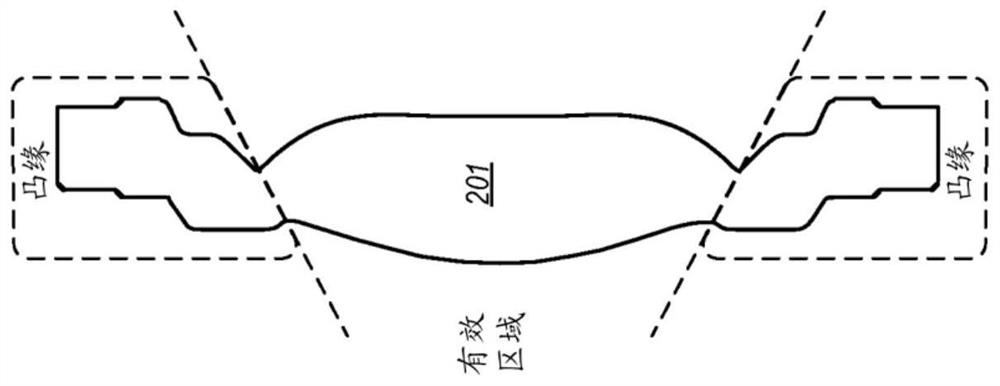

[0034] Conventionally, lens systems for small form factor cameras include lens stacks consisting of two or more refractive lens elements. Each lens element in the lens stack can include an active optical area and a flange area, and can be formed from a transparent optical plastic or glass material. For example, the lens elements may be injection molded optical plastics. While one or more of the lens elements may be formed from transparent optical materials having different optical properties (e.g.,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap