Energy-saving and environment-friendly gasket cutting equipment

An energy-saving, environmentally friendly, gasket technology, applied in metal processing, household components, other household appliances, etc., can solve the problem of gaskets becoming waste, unable to guarantee edge parts, etc., to achieve the effect of easy trimming work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

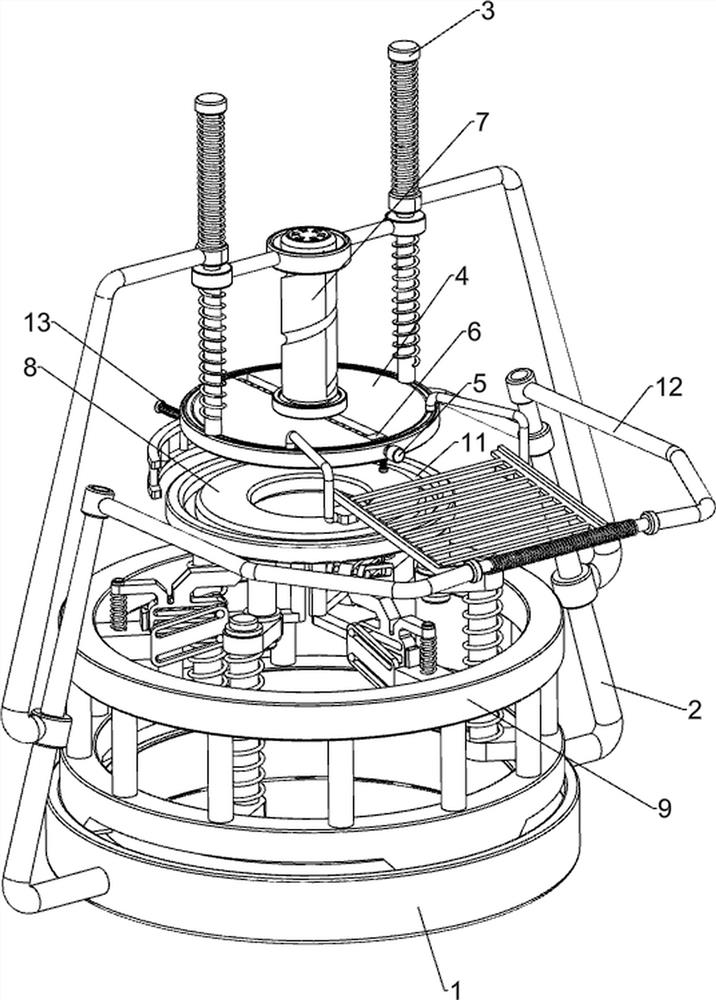

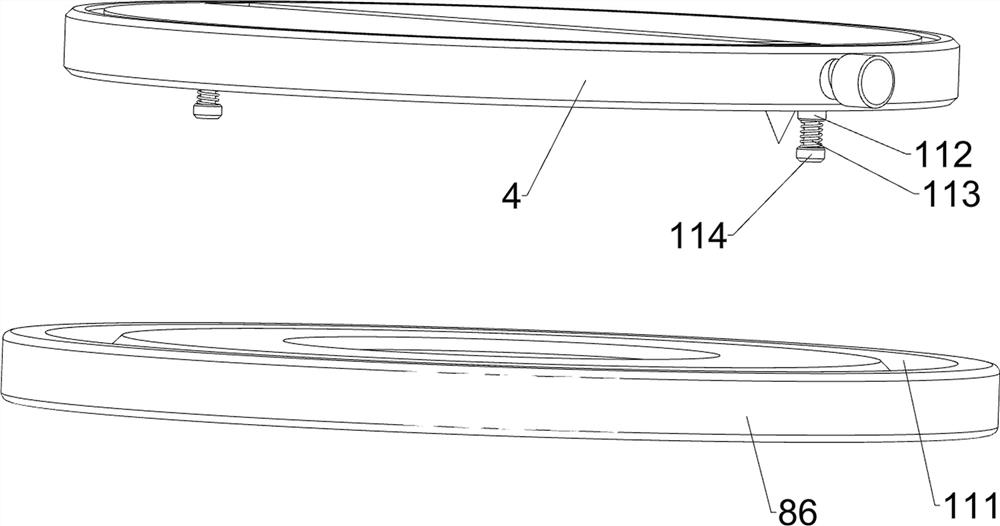

[0024] A kind of energy-saving and environment-friendly gasket cutting equipment, refer to figure 1 As shown, it includes a base 1, a first mounting rod 2, a guide rod 3, a mounting plate 4, a worm 5, a cutting tool 6, a trimming mechanism 7 and a placement mechanism 8, and the left and right sides of the base 1 are provided with a first mounting rod 2. , the trimming mechanism 7 is connected between the first mounting rods 2, the trimming mechanism 7 parts are slidingly provided with guide rods 3, the bottoms of the guiding rods 3 are slidingly connected with mounting discs 4, and the middle part of the mounting discs 4 is rotatably provided with a worm 5. A cutting tool 6 is threaded on the worm 5 , and a placement mechanism 8 is provided on the top of the base 1 .

[0025] refer to figure 2 As shown, the trimming mechanism 7 includes a second mounting rod 71, a first spring 72, a second spring 73, a force plate 74, a groove tube 75 and a lower pressing rod 76, and the low...

Embodiment 2

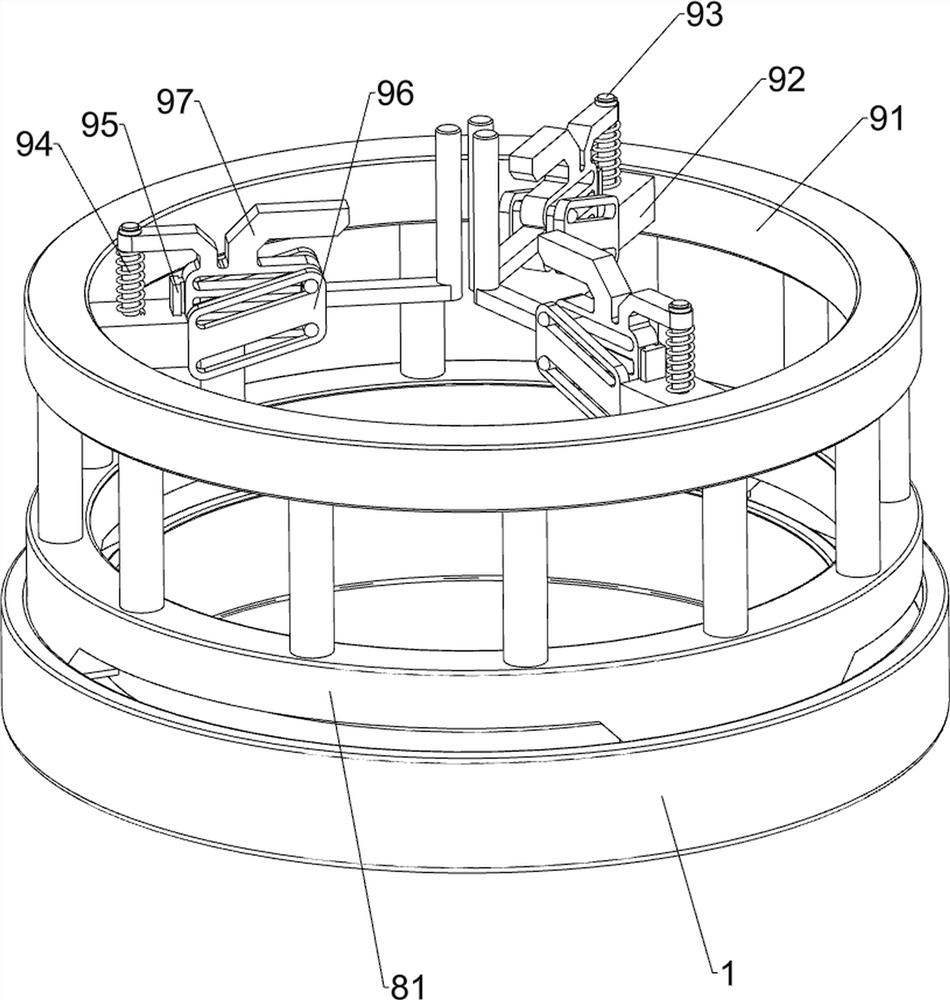

[0029] On the basis of embodiment 1, refer to Figure 4 As shown, it also includes a spreading mechanism 9, and the spreading mechanism 9 includes a spreading frame 91, a second mounting block 92, a first guide post 93, a fourth spring 94, a slide block 95, a slide plate 96 and a pressing plate 97, and the placement frame The top of 81 is provided with a stretching frame 91, and the inner side of the stretching frame 91 is evenly provided with three second mounting blocks 92, and the top of the second mounting block 92 is provided with a first guide column 93, and the sliding type on the first guiding column 93 is provided with a slide block 95 , the inner side of the slider 95 is provided with a pressure plate 97, the fourth spring 94 is connected between the pressure plate 97 on the same side and the first guide column 93, and two slide plates 96 are arranged on the inner side of the second mounting block 92, and the slide plate on the same side 96 and the pressing plate 97 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com