Clamping jaw mechanism of vertical packaging machine

A vertical packaging machine and jaw technology, applied in the field of jaw mechanism, can solve problems such as inability to adjust the inclination angle, unqualified product packaging, insufficient accumulation, etc., and achieve the effect of simple structure, reasonable design, and reduced mutual impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

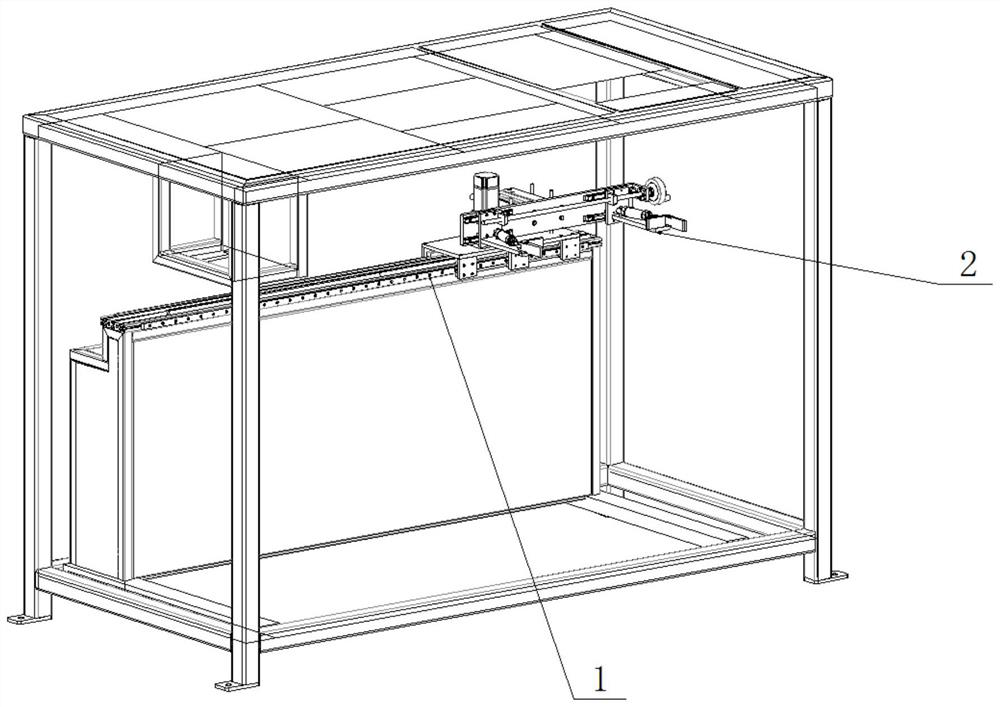

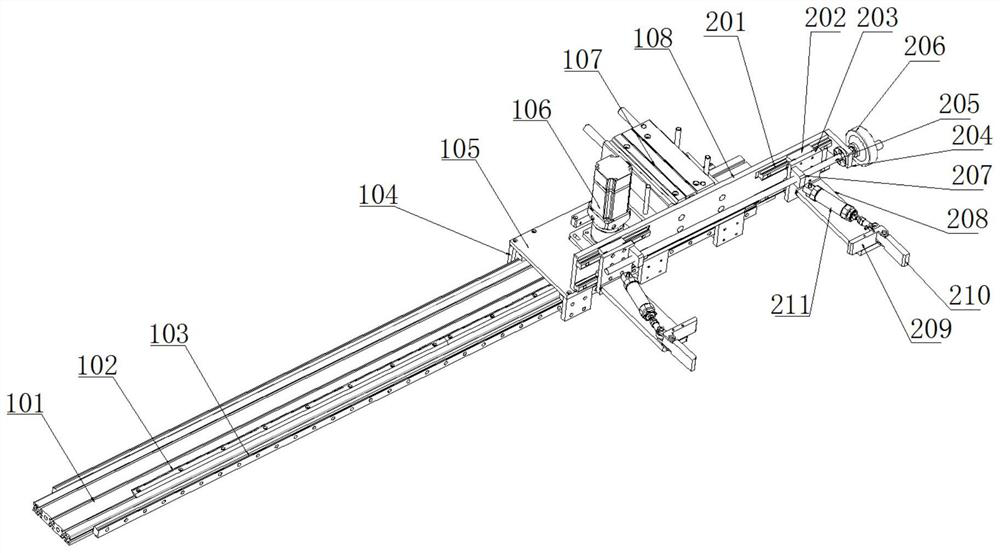

[0032] Such as figure 1 As shown, a jaw mechanism of a vertical packaging machine includes a stroke part 1 and a clamping part 2 connected to the stroke part 1, and the stroke part 1 drives the clamping part 2 to move along the X-axis or the Y-axis direction;

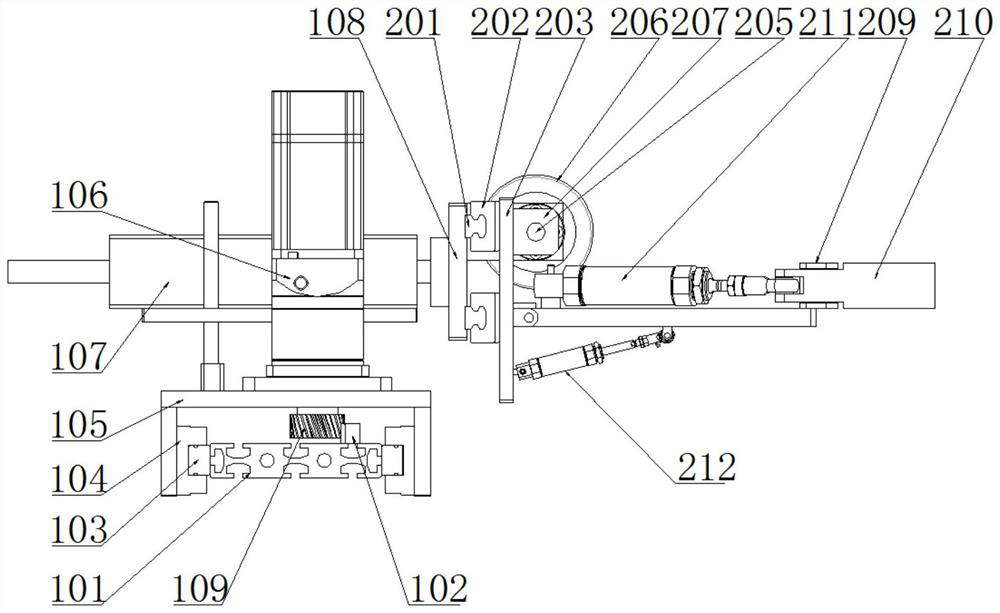

[0033] Such as figure 2 As shown, the stroke part 1 includes an X-axis moving component and a Y-axis moving component, the Y-axis moving component is connected to the X-axis moving component, and the clamping part 2 is connected to the Y-axis moving component;

[0034] The X-axis moving assembly includes a fixed plate 101, a rack 102 connected to the upper end of the fixed plate 101, a first chute seat 103 connected to the two side walls of the fixed plate 101, and several A first slide block 104, a support plate 105 connected to the upper end of the first slide block 104, and a travel motor 106 connected to the support plate 105, the output shaft of the travel motor 106 runs through the support plate 105, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com