Microphone capsule, microphone assembly comprising multiple microphone capsules, and method for calibrating a microphone array

A technology of microphones and carbon capsules, applied in the direction of microphone signal combination, electrostatic transducer microphones, sensors, etc., can solve problems such as error-prone, difficult and expensive, and result distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

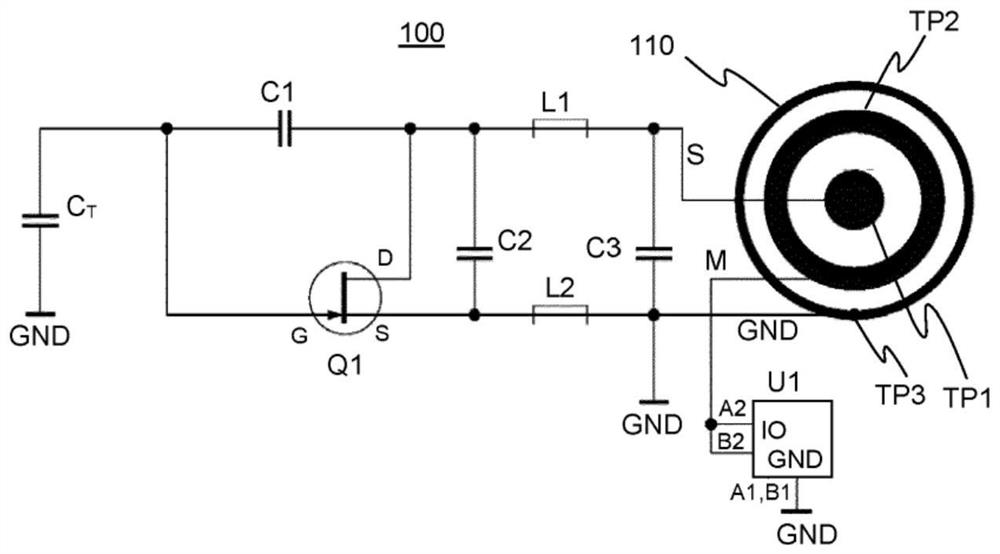

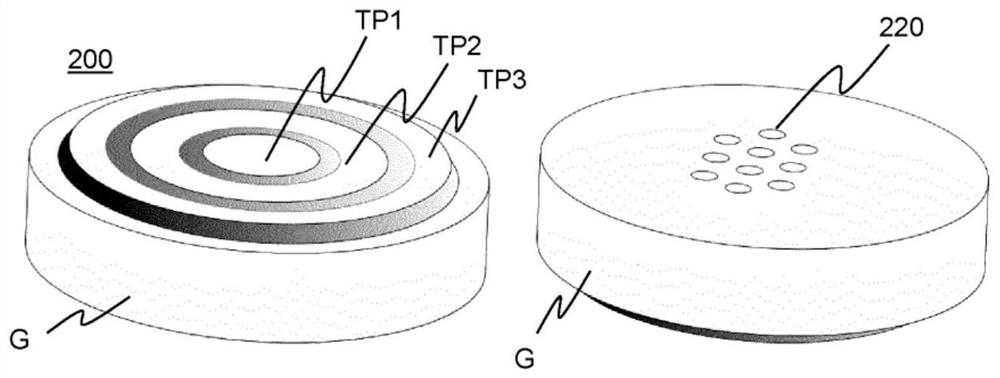

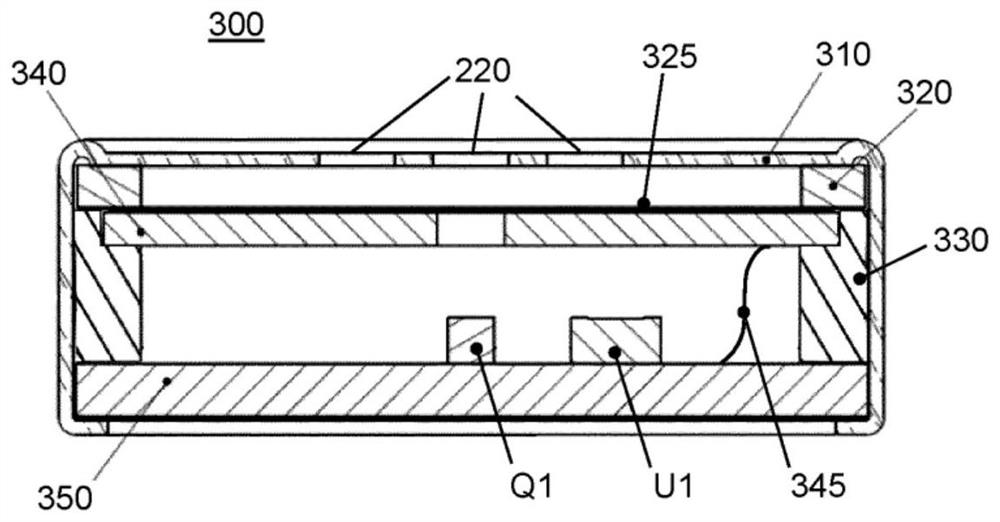

[0017] figure 1 In one embodiment, a circuit diagram 100 of a microphone capsule according to the invention is shown. In the housing of the microphone capsule there are: an electrostatic sound transducer CT, which is represented here by its equivalent circuit symbol as a capacitor; an amplifier element Q1 , for example a FET; and a memory element U1 . The electrostatic sound transducer CT can be, for example, an electret microphone or a condenser microphone. Amplifier element Q1 also acts as an impedance converter in the electret microphone and can thus have a very low gain, for example 1. In addition, different analog components C1-C3, L1, L2 are included for frequency response correction, interference protection, adaptation or pre-filtering. These are optional, but common in electrostatic microphone capsules. For example, C2, C3, L1, and L2 are used to filter out high-frequency interference signals. The microphone capsules are connected via electrical contacts 110 , whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com