Aerial cable

A high-altitude cable and cable technology, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of high work intensity of installers, difficulty in tightening the cable body, and large force of cable use, so as to reduce work intensity, simplify and save labor The effect of tightening and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

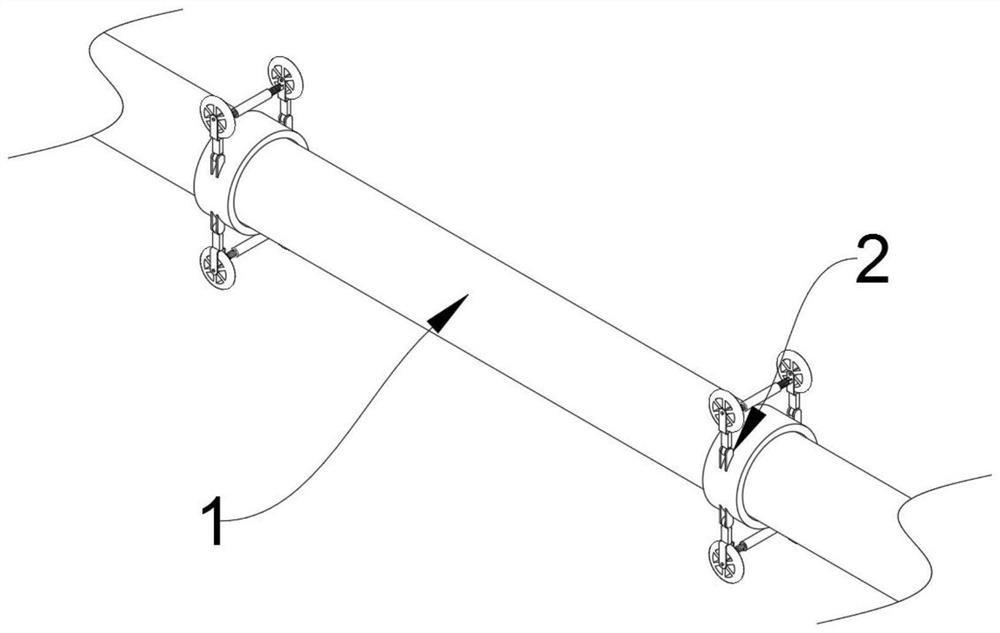

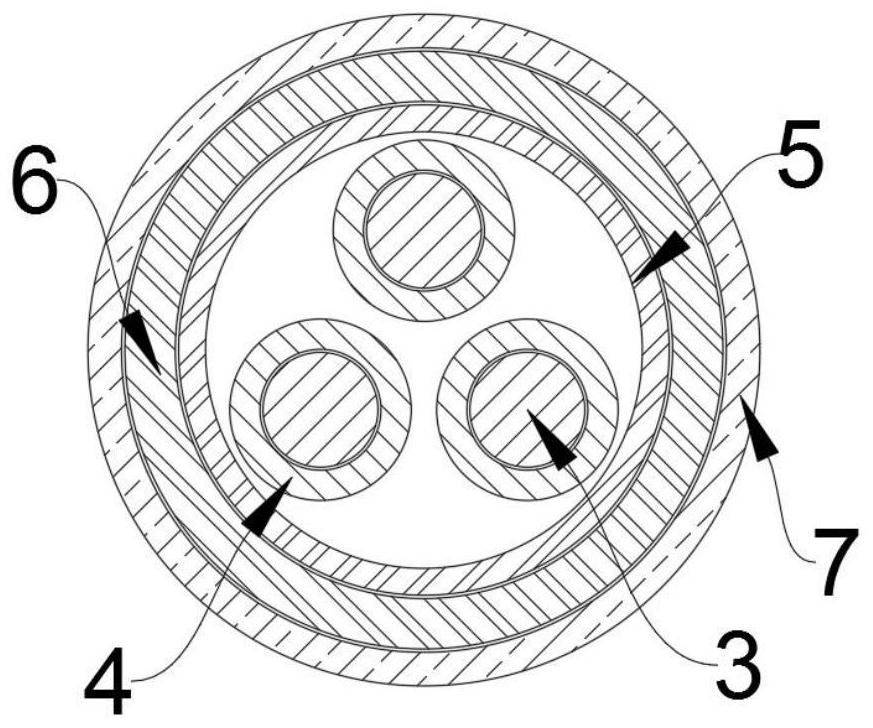

[0032] see Figure 1-4 As shown, the present invention is a high-altitude cable, including a cable body 1. The cable body 1 includes a plurality of cable copper cores 3, and the outer sides of the cable copper cores 3 are provided with copper core protective sleeves 4 for protecting the cable copper cores 3. To protect and separate the cable copper core 3 from the adjacent cable copper core 3, an insulating protective layer 5 is provided on the outside of the plurality of copper core protective sleeves 4 to isolate and insulate the electric energy released by the cable copper core 3 The outer side of the protective layer 5 is provided with a metal braided protective layer 6, which is used to protect the copper core protective sheath 4 to prevent the copper core protective sheath 4 from being damaged by external force, and the outer side of the metal braided protective layer 6 is provided with a cable protective layer 7 for Prevent the metal braided protective layer 6 from bein...

Embodiment 2

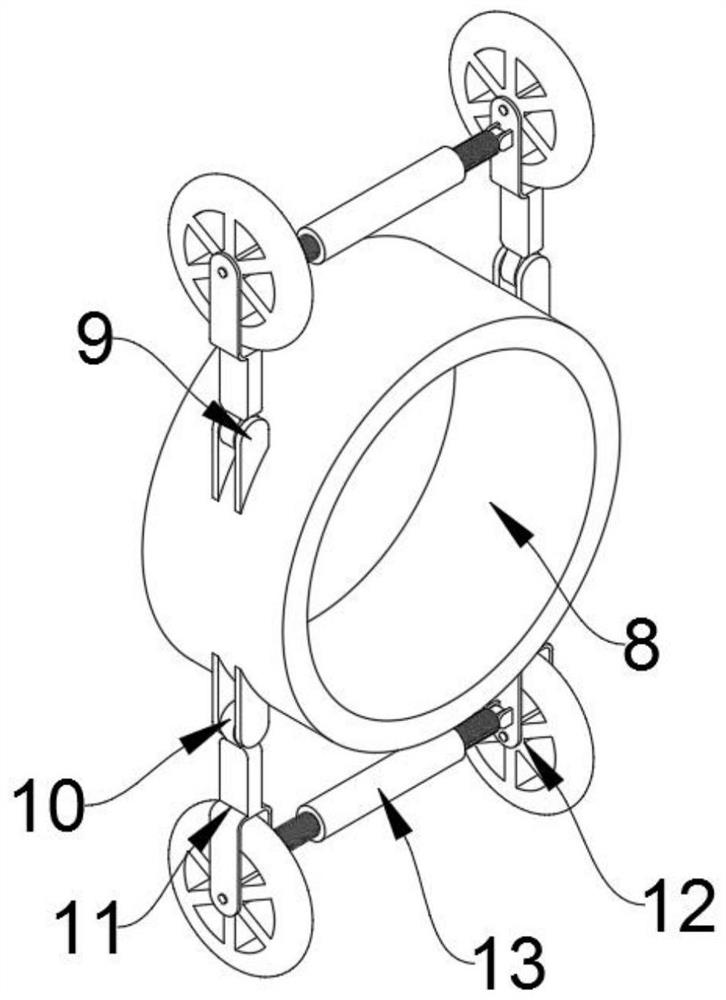

[0038] see Figure 5-8 As shown, another auxiliary mechanism 2 is disclosed on the basis of Embodiment 1. The auxiliary mechanism 2 includes a second cable fixing ring 29, and the upper end of the second cable fixing ring 29 is fixedly connected with a C-shaped fixing bracket 18, and the C-shaped The lower end of one side of the fixed frame 18 is fixedly connected with a shaft plate limit ring 19, and the inside of the shaft plate limit ring 19 is slidably connected with a lifting shaft plate 28, and the upper end of the lifting shaft plate 28 is fixedly connected with a guide shaft plate 24, and the guide shaft plate Both ends of 24 are provided with a first cable guiding slope;

[0039] The lower end of the shaft plate limit ring 19 is fixedly connected with a spring limit ring 20, and the inside of the spring limit ring 20 is provided with a return force spring 22, and the upper end of the return force spring 22 is fixedly connected with the lifting shaft plate 28;

[0040] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com