Remote control intelligent trolley for logistics in industrial park

A remote control and smart car technology, applied in two-dimensional position/channel control, motor vehicles, non-electric variable control, etc., can solve the problems of slow logistics distribution and low running speed of the car, to avoid collision offset, Avoid the effect of low delivery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

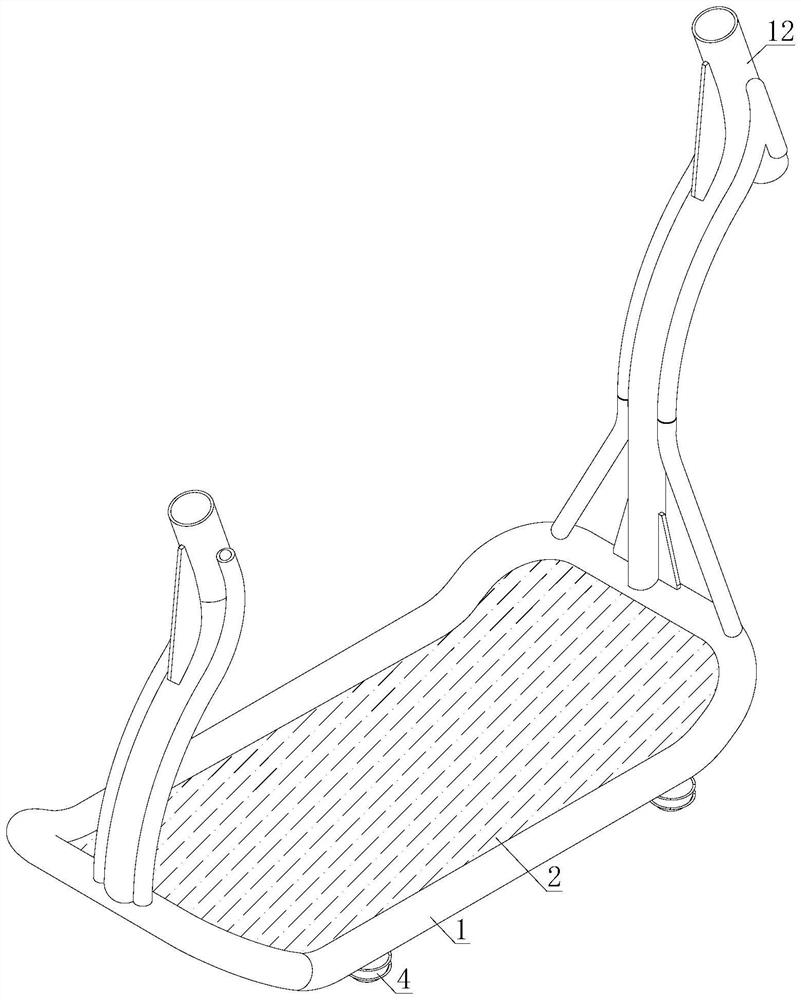

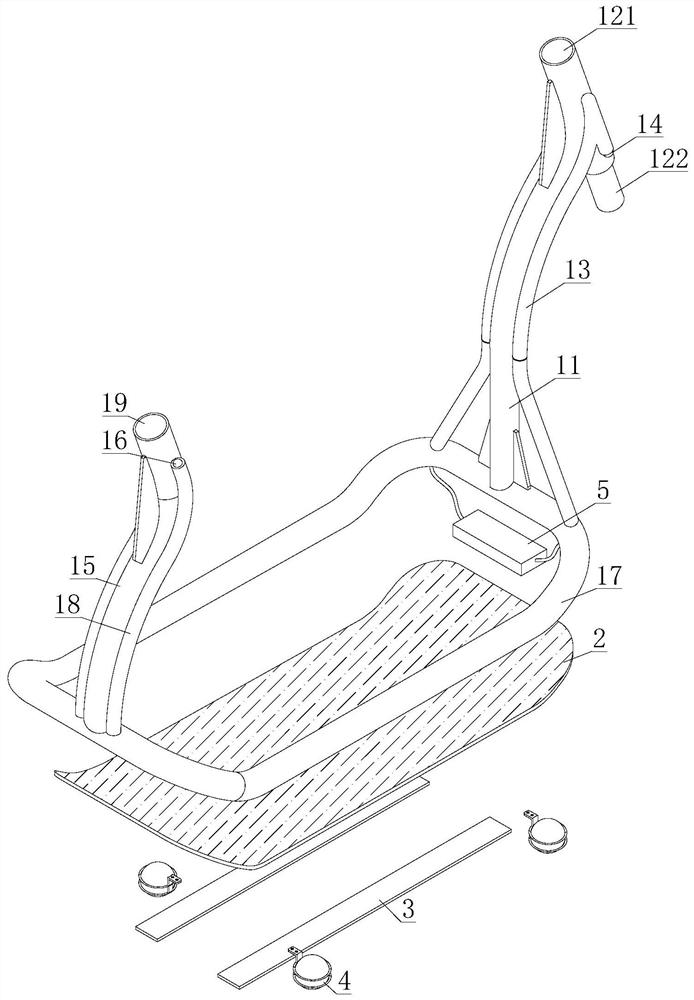

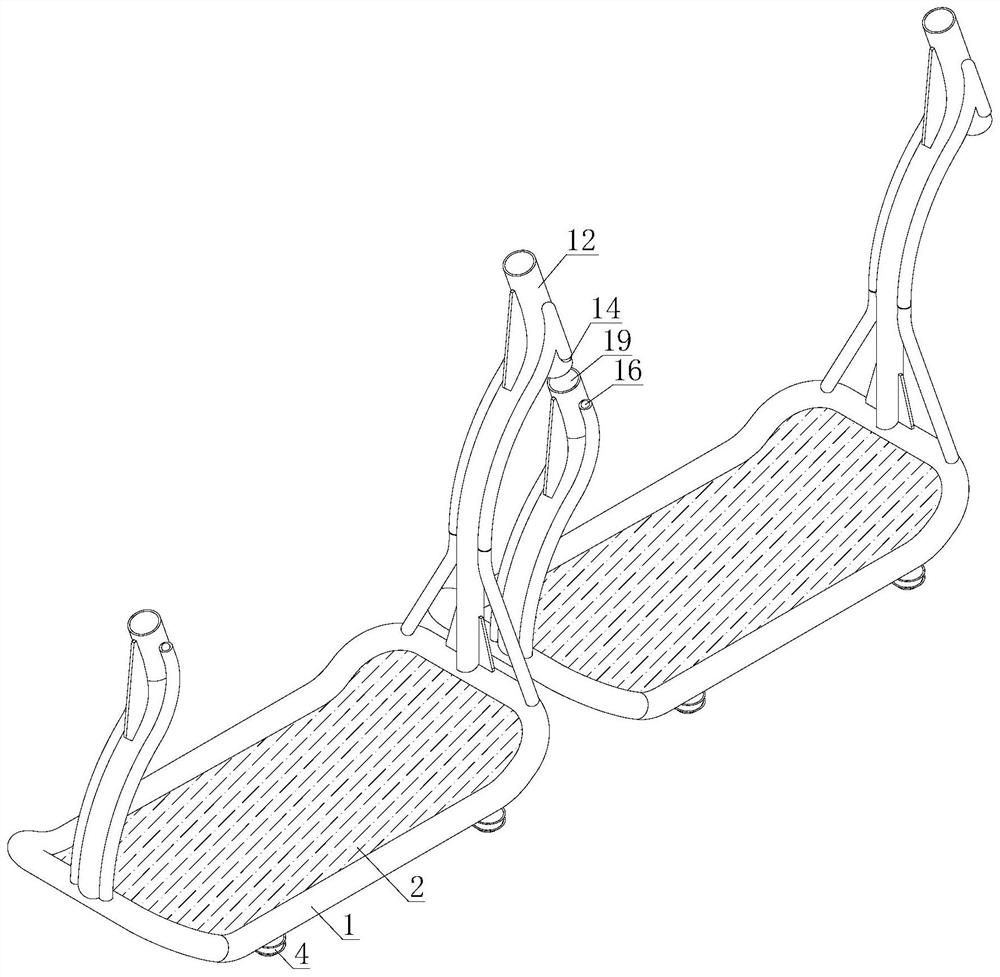

[0030] refer to Figure 1 to Figure 3 , a remote control smart car used for internal logistics in industrial areas, including a frame 1, a bottom plate 2, a magnetic strip 3, a roller assembly 4 and a control center 5, the bottom of the frame 1 is welded with a bottom plate 2, and the bottom surface of the bottom plate 2 The top is fixedly connected with a magnetic strip 3, and the four corners of the bottom surface of the bottom plate 2 are fixedly connected with a roller assembly 4 by bolts, and a control center 5 is installed on the front end of the vehicle frame 1; a magnetic circuit is laid on the ground below the vehicle frame 1. The line and the magnetic strip 3 attract each other through magnetic force. The smart car is an AGV car that uses magnetic guidance as the driving force. The planned magnetic line is laid in advance in the logistics factory area, and the VGA car moves along the magnetic line.

[0031] The vehicle frame 1 includes a front support rod 11, a cylin...

Embodiment 3

[0036] refer to Figure 6 to Figure 7 The difference between the present embodiment and the first embodiment is only that a handlebar 6 is added in this embodiment, the upper end of the cylinder body 121 is provided with a handlebar 6, and the handlebar 6 includes a cylinder body 61, a screw rod 62, a T frame 63 and a handle 64 , the cylinder body 61 is welded to the upper end of the cylinder body 121, and the inner wall of the cylinder body 61 is threaded, and a screw rod 62 is screwed through the thread, the upper end of the screw rod 62 is welded with a T frame 63, and both ends of the T frame 63 are fixedly connected With the handle 64, the dolly after adding the handle 6 can not only move through magnetic guidance, but also push the dolly to move by manually holding the handle 64.

[0037] Embodiment three

[0038] refer to Figure 8 to Figure 9 The difference between the present embodiment and the second embodiment is only that a buffer device 7 is added in this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com