Exhaust sensor fault detection method and device, air conditioner and storage medium

An exhaust sensor and fault detection technology, which is applied in the field of equipment fault handling, can solve problems such as false alarms of exhaust sensor faults, and achieve the effects of avoiding fault false alarms, solving false alarms of exhaust sensor faults, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

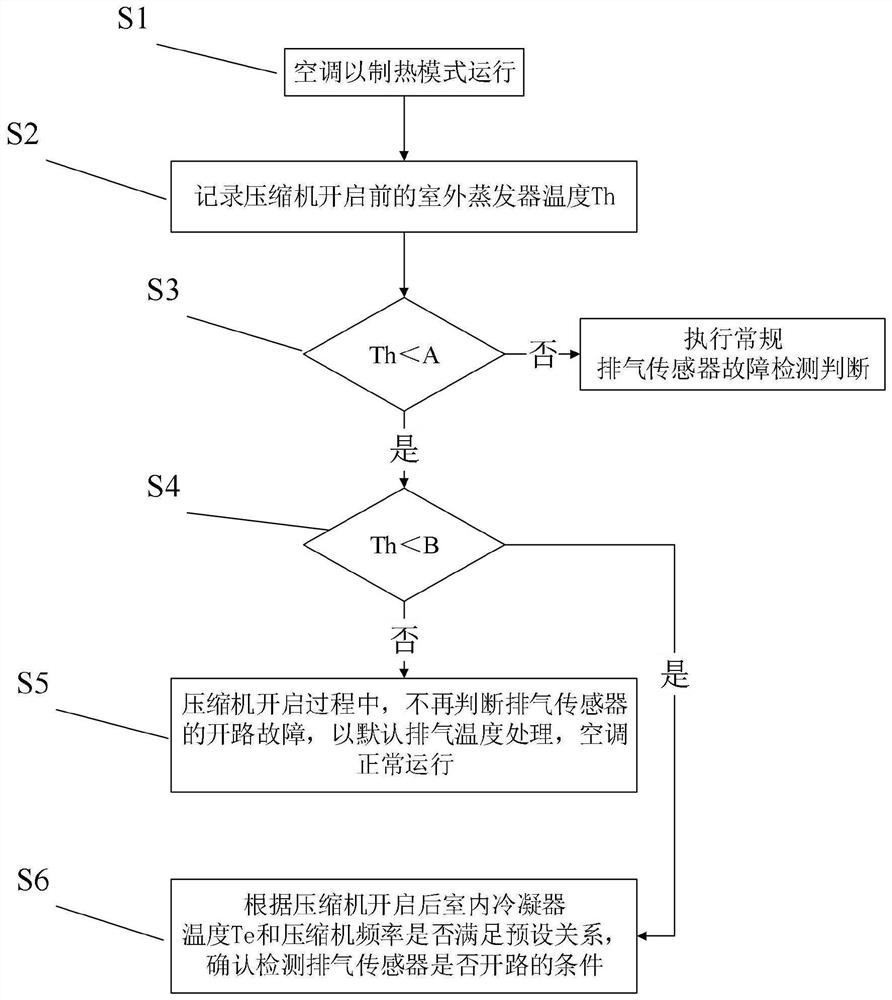

[0047] The invention discloses a fault detection method of an exhaust sensor, which comprises the following steps:

[0048] S1: The air conditioner operates in heating mode;

[0049] S2: Record the outdoor evaporator temperature Th before the compressor is turned on;

[0050] S3: Determine whether the temperature Th of the outdoor evaporator before starting the machine is lower than the first preset threshold value A, if not, perform a conventional exhaust sensor fault detection procedure; if so, enter S4;

[0051] S4: If the temperature Th of the outdoor evaporator before starting up is less than the second preset threshold B, go to S5;

[0052] S5: During the start-up process of the compressor, the open-circuit fault of the exhaust sensor is no longer judged, and the default exhaust temperature is used for processing, and the air conditioner operates normally;

[0053]Among them, the first preset threshold value A, the second preset threshold value B, and the default exhau...

Embodiment 2

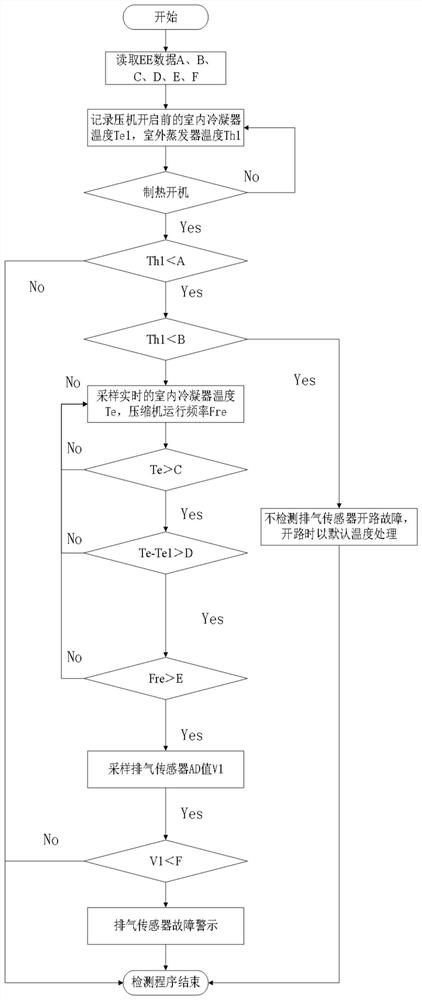

[0079] The invention discloses a fault detection method of an exhaust gas sensor, which specifically includes the following steps:

[0080] ST1: start the air conditioner;

[0081] ST2: Read pre-stored data first preset threshold value A, second preset threshold value B, third preset threshold value C, fourth preset threshold value D, fifth preset threshold value E, fixed threshold value F ;

[0082] ST3: Record the indoor condenser temperature Te and the outdoor evaporator temperature Th1 before the compressor is turned on;

[0083] ST4: Determine whether it is heating and starting, if so, enter ST5; if not, return to ST3;

[0084] ST5: Determine whether Th

[0085] ST6: Determine whether Th

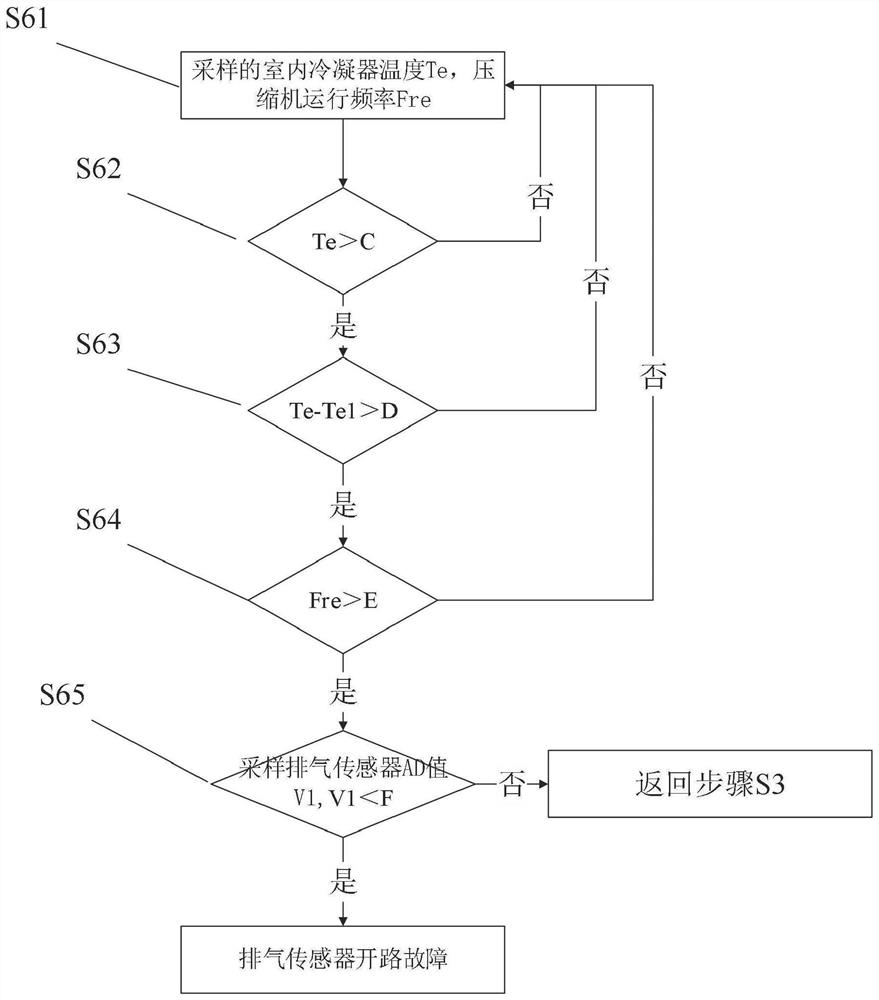

[0086] ST7: Sampling real-time indoor condenser temperature Te, compressor operating frequency Fre;

[0087] ST8: Determine whether Te>C, if yes, enter ST9; if not, return to ST7;

[0088] ST9: Det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com